How to choose waste tire pyrolysis plant? product introduction

For customers who want to start waste tire pyrolysis business, they will firstly consider that how to choose the waste tire pyrolysis plant. Professional waste tire pyrolysis plants suppliers tell you that if you want to buy a set of suitable waste tire pyrolysis plant, you can refer to the following aspects.

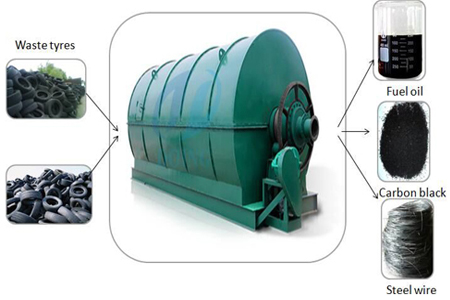

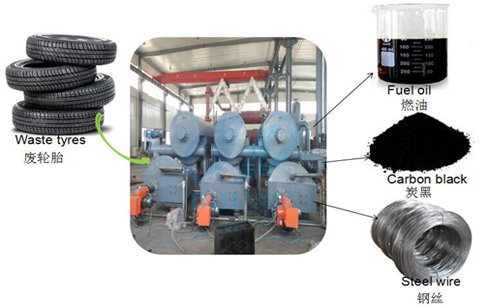

waste tyre pyrolysis plant

waste tyre pyrolysis plant

1.Choose a reliable supplier

It is very important to choose a reliable supplier. There are equipment manufacturing companies and equipment trading companies on the market. The equipment manufacturing companies can produce machines in their own factories, while equipment trading companies need to buy machines from equipment manufacturing companies and then sell them to customers at higher price. Therefore, You can investigate the background of suppliers by browsing their websites, searching industry rankings, Alibaba platform inquiries, etc., to find some suppliers with their own production factories and long-established companies, to eliminate some newly established suppliers and trading companies.

2.Choose a good quality pyrolysis reactor.

Pyrolysis reactor is the main part of a waste tyre pyrolysis plant. So the quality of the pyrolysis reactor directly decide the service life of the waste tyre pyrolysis plant, And the material, the thickness and the welding of the pyrolysis reactor decide the quality of the pyrolysis reactor is good or not. Doing Group waste tyre pyrolysis plant adopts 16mm Q245R boiler plate to produce the pyrolysis reactor. The Q245R boiler plate could make sure the pyrolysis reactor could bear the required high temperature heating. And 16mm thickness of the pyrolysis reactor plate is the best choice by considering about the heat transfer factor. Also our pyrolysis reactor is welded by auto-welding technology with three-step welding to make sure the welding of the pyrolysis reactor is perfect, thus to avoid the crack during long time high temperature operation.

the pyrolysis reactor

the pyrolysis reactor

3. Choose a professional supplier with an experienced installation team

Waste tire pyrolysis plant is not like a small product or common used daily supplies, without the professional instruction or guidance and training, it’s very hard for anyone to install and operate the waste tire pyrolysis plant well. So before you choose to buy the waste tire pyrolysis plant, better at first to make sure the supplier is professional with an experienced installation team, which could give you a better after-sale service after you spent the money on the machine. Henan Doing's engineers with over ten years’ waste tire pyrolysis plant installation experience will be dispatched to your place to provide technical service in guiding plant installation, plant commissioning as well as worker training, enabling your workers to master all the operating skills needed and can operate the plant on their own.

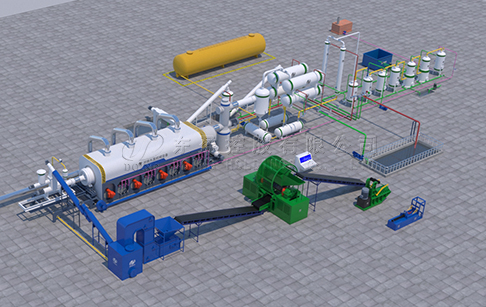

Doing Group instillation machine

Doing Group instillation machine

In addition to the factors mentioned above, there are many factors affect the waste tire pyrolysis plant quality. Doing Group suggests that customers should consider comprehensively when purchasing equipment. If you want to buy the waste tire pyrolysis plant at factory prices, please contact us feel free.

| Technical parameter of how to choose waste tire pyrolysis plant? | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd