Continuous waste tire pyrolysis plant product introduction

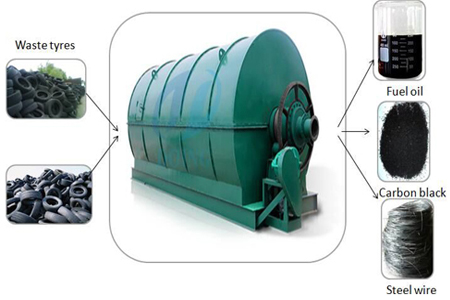

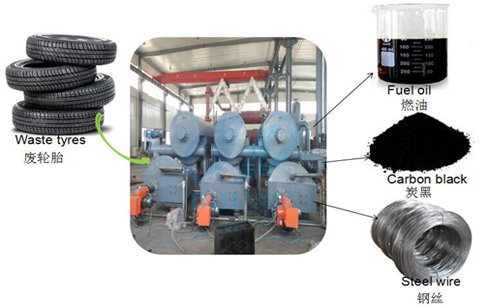

Waste tire pyrolysis plant is a specialized equipment used to convert waste tires into fuel oil. It employs pyrolysis technology, which is a chemical change that converts a substance (usually a high molecular compound) into one or more substances (usually low molecular compounds) by heating with high temperature. Doing new type continuous waste tire pyrolysis plant has better performance on operation, energy-saving, labor-saving, time-saving and oil output.

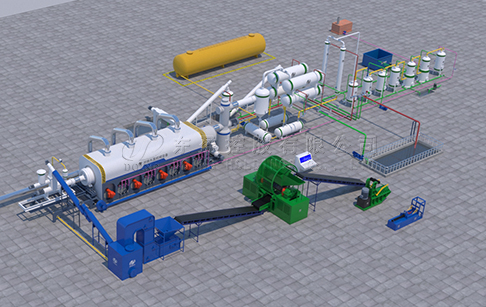

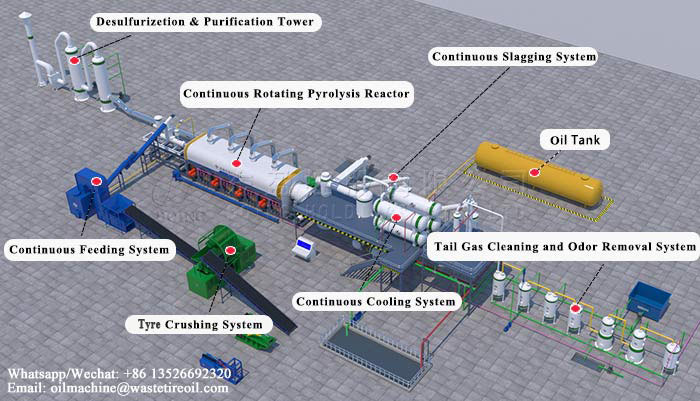

The main components of continuous tyre pyrolysis plant: waste tire to rubber powder processing system (including waste steel wire drawing/tire side wall cutting machine, tire cutting machine, tyre shredders, etc.), screw feeder, pyrolysis reactor, multistage oil-gas condensers, oil tanks, water cooled screw discharger, carbon black storage bags, syn-gas purification system, exhaust gas cleaning devices, dust collection system, etc.

Components of continuous waste tire pyrolysis plant

The detailed process of continuous waste tire pyrolysis plant is as follows:

Continuous tire pyrolysis plant working process

1. Drawing steel wire

Put the waste tires into the steel wire drawing machine to pull out steel wire.

2. Crushing waste tires

Crush the leftover waste tires in the shredder to get fine pieces of tires.

3. Pyrolysis

Convey the finely shredded tire pieces, rubber powder into the pyrolysis reactor to pyrolyze them into oil gas, non-condensable gas, and carbon black.

4. Condensation

The oil gas is buffered by the buffer tank and then enters the condensing system which has sufficient contact area and high efficiency. Finally, the condensed oil, also called tire pyrolysis oil (TPO)/ tire derived fuel (TDF), is collected into the oil tank.

5. Non-condensable gas

After condensing, there is some non-condensable gas, such as methane and ethane, left. It will be recycled to heat pyrolysis reactor after cleaned by tail gas purification system.

6. Purifying flue gas

The flue gas from furnace will be purified by desulfurization tower, and then discharged to air meeting the environmental protection standards.

7. Slag discharging

The carbon black obtained from pyrolysis of waste tires is discharged through the carbon black discharging device including spiral elevator and wind transport system.

DOING Continuous Waste Tire Pyrolysis Plant Advantages Display:

1. Various capacities (covering from 15Ton to 50Ton per set), Customized design, configuration adjusted to meet your different requirements and save your investment cost.

DOING continuous tire pyrolysis plant with different capacities

2. Fully enclosed feeding and carbon black discharge system with good sealing effect ensures a clean production environment.

3. Multiple stage oil-gas cooling system, on the one hand, can ensure sufficient cooling efficiency and high oil output rate, and on the other hand, it can also ensure that the pipeline is not easily blocked.

4. It adopts environmental exhaust gas treatment and protection design, such as desulfurization tower, denitrification tower and dedusting system, which can be adjusted according to the local EIA standard and ensures the legal emission of exhaust gas.

Environmental equipment of continuous waste tire pyrolysis plant

5. Intellegient operation and control PLC system, with real-time monitoring and stage statistics of the continuous waste tire pyrolysis to fuel oil production process, can realize the precise feeding, temperature& pressure control.

Continuous Pyrolysis Plant Manufacturer-Henan Doing Group

As an experienced and world-leading manufacturer of continuous waste tire pyrolysis plants, Henan DOING Group takes pride in investing in machine R&D, innovation, improvement and delivering a one-stop service to all our customers.

Continuous waste tire pyrolysis plant manufacturer services

Henan DOING Group understands the important role of installation experience, successful practices and associated customer service. That’s why Henan Doing provides seamless pre-sales, on-sale and after-sales support. From project initiation to completion, our dedicated sales manager and expert technical engineers will assist you in setting up the waste tire pyrolysis plant.

For continuous pyrolysis project cases, our Henan Doing Company is one of the very few manufacturers and suppliers with rich installation experience. Great integrated strength is why so many customers choose DOING Group for their waste tire to oil recycling pyrolysis recycling projects.

The following is an example of our successful fully continuous waste tire pyrolysis plants for your reference.

If you are interested in DOING continuous waste tire pyrolysis plant for sale, please leave your contact information below, and our project manager will contact you ASAP. Henan Doing Group can also provide you with customized waste tire pyrolysis plants according to your needs or budget.

| Technical parameter of continuous waste tire pyrolysis plant | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd