Waste oil distillation plant product introduction

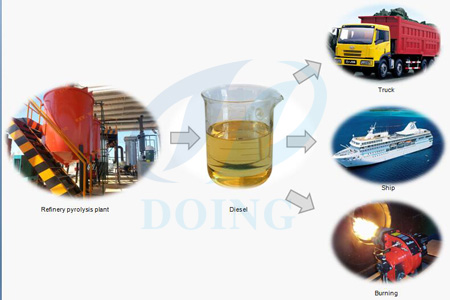

The waste oil distillation plant is mainly to convert the the waste oil to diesel,it is an industry process that crude oil is processed and refined into more useful products such as petroleum, diesel, heating oil,and liquefied petroleum gas.We Xinxiang doing renewable energy equipment co.ltd waste oil distillation plant is used to convert the used motor oil, used engine oil,plastic oil and tyre oil to diesel with great financial profits. The speciations of the plant are as below:

1. We can get stand diesel, after the waste oil such as waste tyre oil, waste plastic oil waste engine oil processed we will get stand diesel.

2. High oil yield rate. We have a special designed equipment to improve the oil yield rate.

3. The plant is very profitable

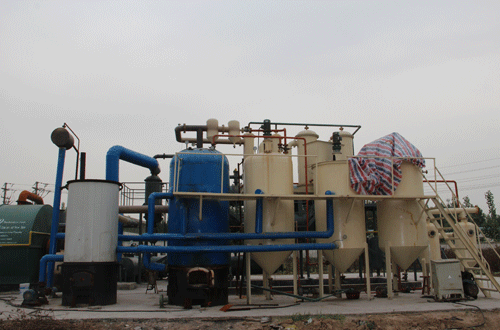

The process of the waste oil distillation plant:

Feed liquid waste oil-heating-catalytic cracking-cracking-fractionation-cooling liquid-decompression-flammable gas recovery-flammable gas combustion-desulfurization

The raw material and the oil yield we analysis:

Waste engine oil:85%-90%

Waste plastic oil: 90%

Tyre oil: 85%-90%

The final products of the waste oil distillation are fuel oil(mainly used for making electricity, waste gas(recycled to furnace for heating reactor) , Slag

| Technical parameter of waste oil distillation plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | waste oil, plastic oil, tyre oil, |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd