Waste tyre oil plant product introduction

Waste tyre oil plant is the waste to energy recycling machine to convert the waste tyre to fuel oil, carbon black, steel wire, syn-gas. We Xinxiang doing renewable equipment co.ltd are the professional supplier and manufacturer of the waste tyre oil plant. With years of research, development and innovation, we have mature technology to manufacture high quality tyre oil plants.

1. DOING waste tyre oil plant for sale

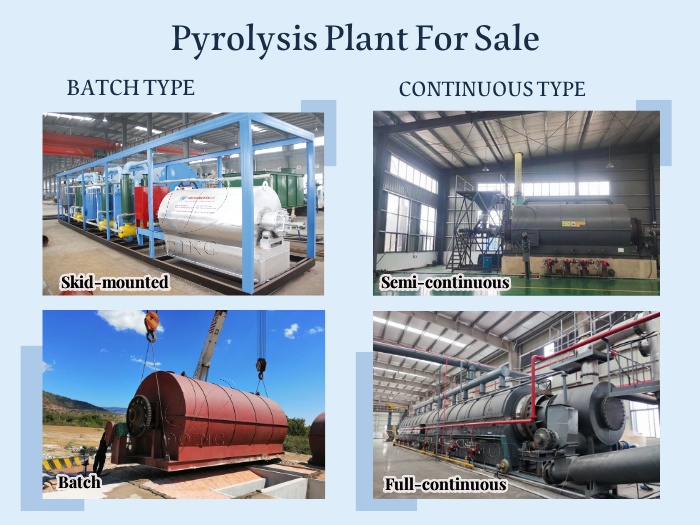

Capacity 100/500kg, 1-50TPD, various scales to choose from

Machine type skid-mounted, batch type, semi-continuous type, fully continuous waste tyre oil plant

Different types of waste tire oil plant for sale

2. Waste tire oil plant component parts and working process:

The pyrolysis reactor and condensers are the two key parts of the waste tyre oil plant. Pyrolysis reactor is the part that heats the waste tyre. The waste tyre in the reactor will be heated to a temperature, and then the waste tyre will vaporize. The oil gas will be condensed into liquid in the condenser. Then we can collect the liquid tire pyrolysis oil.

Here is the 3D video of our waste tire pyrolysis plant working process for your reference.

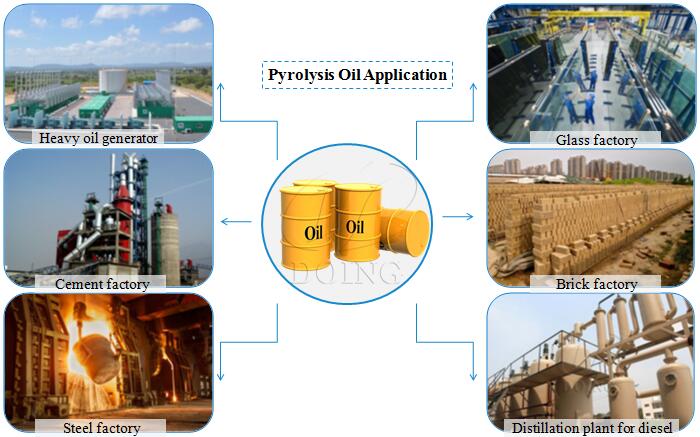

3. Waste tyre oil applications

The tire pyrolysis oil obtained from waste tyre oil plant is a good alternative energy to the traditional energy. It has good fuel value. The calorific value of tire pyrolysis oil is about 10000~10200 kcal, so the tire pyrolysis oil can be widely used in many industries, such as iron factories, steel factories, power plants, cement factories, restaurants, etc. And you can also further refine the tire pyrolysis oil into diesel fuel with our waste oil distillation plant.

Waste tire oil plant applications

4. The environmental protection devices of DOING waste tyre oil plant

During the process of converting waste tyre oil to fuel oil, there will be no waste generated. We all know that industrial pollution is mainly about waste water, waste dust and waste gas pollution. And DOING's engineer team took the environmental protection devices into consideration while designing the waste tyre oil plant.

(1)No waste water: The water used to cool the oil gas is non-contact with the process. So the water is clean and can be recycled many times.

(2)No flying dust: We have the carbon black discharging system to discharge the carbon black. It's totally sealed and has no dust.

(3) Gas emission: DOING waste tyre oil plant is equipped with the desulfurization system to deal with the waste gas. Therefore, it can meet different countries' gas emission standards.

Waste tyre oil plant project cases installed by DOING Company

Till now, we have exported the waste tyre oil plant to more than 90 countries in the world such as India, Russia, Italy, France, Mexico, Pakistan, Malaysia, Iran, Turkey, Nigeria, Brazil, South Africa and so on. We offer perfect service for pre-sale and after-dale service, and 1 year warranty time. For every set sold tyre oil plant, there will be one technician dispatched to your country to help install the plant, design the foundation, and train your workers and so on based on your requirements.

Please feel free to send us your inquiry about DOING waste tyre oil plants if you are interested.

| Technical parameter of waste tyre oil plant | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, waste plastic, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd