The pyrolysis plant is a recycling machine that can convert waste plastic/tyre/oil sludge/coal tar oil to fuel oil. The final product of the pyrolysis plant is mainly fuel oil (can be further refined into diesel), carbon black, and signal gas. (Steel wire for waste tyre). The prolysis plant is a renewable and environmental equipment that deals with the waste and changes the waste into energy.

Waste plastics/tyres/oil sludge to fuel oil plant

◆ The principle of the pyrolysis plant is as below:

When the raw material waste tyre/plastic heated in the reactor, then raw material will generate some oil gas. When the oil gas goes into the condenser, the oil gas will be condensed into liquid fuel oil. The oil gas which cannot be condensed will be recycled to the burner to heat the reactor. So just little energy is required to run the pyrolysis plant. It's quite energy saving.

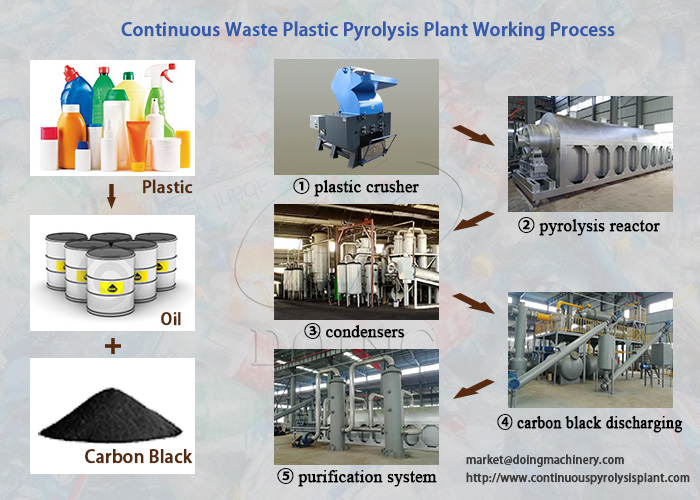

◆ Pyrolysis Plant Working Process:

Next, let's take the waste plastic pyrolysis plant as an example to see how the pyrolysis plant works.

1. Use the feeding machine to send the waste plastic into the pyrolysis reactor, and then heat the pyrolysis reactor with fuel;

2. When the temperature of the pyrolysis reactor reaches a certain temperature, oil gas will be produced, and the oil gas will be cooled down into pyrolysis oil through the cooling system.

Uncondensable but combustible gas can be recycled by industrial pressure vessel to heat pyrolysis reactor;

3. After the pyrolysis reaction is over, wait for the temperature of the pyrolysis reactor to drop below 40 degrees, and then open the carbon black discharge port of the pyrolysis reactor to discharge carbon black.

4. Collect the carbon black with the carbon black discharge device.

Workflow of continuous waste plastic pyrolysis plant

◆ Pyrolysis Plant Running Videos:

◆ The application of pyrolysis plant final products

1. Fuel oil.

Fuel oil is a good heating fuel, which can be used in many industries, such as steel factories, boiler heating, heavy oil generator, cement factories, etc. Besides, fuel oil can be refined by waste oil distillation machine into diesel fuel, which can be used in diesel generator, heavy machinery or diesel fuel for heating. The current market price of waste tire pyrolysis oil is about US$500 per ton, and the price is still rising. Therefore, waste tire pyrolysis oil can bring huge profits to customers.

Fuel oil application

2. Carbon black.

Carbon black can be made into pellets for burning and heating, just like coal, or refined into different standards, used as additives for paints, pigments, rubber products, etc. Many of our customers have obtained huge profits from carbon black, which has solved the problem of carbon black shortage in the market to a certain extent.

Carbon black application

◆ Different types of Pyrolysis Plant For Sale:

Doing Group provides two types of waste tire/plastic pyrolysis plant: batch waste tire/plastic pyrolysis plant and continuous waste tire pyrolysis plant. The daily capacity of our pyrolysis plant is between 100KG to 50+T.

1. Batch Type:

①Skid-mounted Pyrolysis Plant: 100KG, 500KG

Features: Free installation, easy for transportation and handling. Suitable for trial running or sciences experiment uses.

②Common Batch Pyrolysis Plant: 1-15TPD

Features: Cost effective, multiple uses, popular choice of most customers

2. Continuous Type:

①Semi-continuous Pyrolysis Plant: 1-15TPD

Features: Equipped with feeding system, labor&energy saving. Higher configuration of batch common batch pyrolysis plant.

②Fully continuous Pyrolysis Plant: 15-50+TPD

Features: 24/7 hours running, high professing efficiency, high profits. Suitable for customers who want to dispose of waste in a large quantity.

Different type pyrolysis plant

DOING Group's pyrolysis plants have been on hot sale in more than 100+ countries and regions, and in good running. By virtue of their stable operation, environmental protection and brilliant performance, our pyrolysis plants won good recognition.If you want to know more information about waste tires/plastic pyrolysis plants, welcome to consult us.