Latest generation plastic to oil machine product introduction

we are xianxiang doing renewable equipment co,ltd.Professional supplier and manufacturer and trader in the plastic/tyre to oil industry in the world.We are the leading company with the original technology.we are the earlist company to engage in the plastic/tyre to oil industry in china.With abundant experience mature technology we imported our products to more than 20 countries in the world.Our pyrolysis plant gains huge reputation for its reliable operation,reasonable price,good quality.

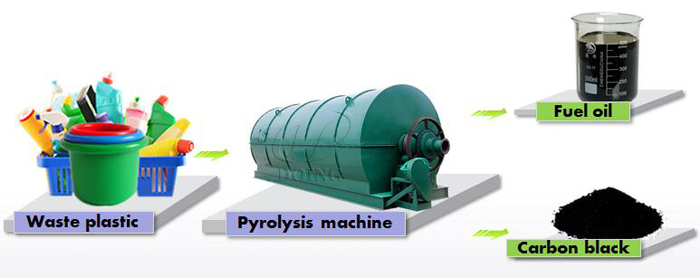

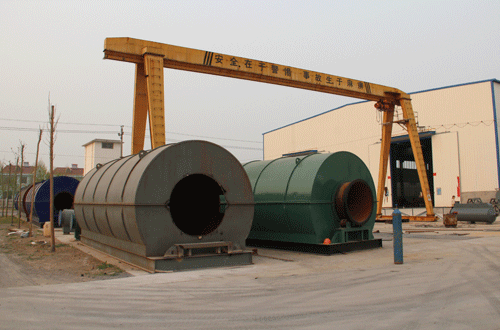

The latest generation convert plastic to oil machine is absolutely new disigned by us.The great advantage of the latest generation plastic to oil machine is that both waste plastic and waste tyre can be processed in the same reactor.As one of the leader of suppliers and manufacturers of plastic to oil pyrolysis plant,the latest generation plastic to oil pyrolysis plant will convert the waste plastic to oil without any pollution. And the quality of the oil is higher than before.

Plastic is playing a more and more important role in our life .it is widely used in facilities manufacturing industries, aspects of our life and so on .it is the sign that symbolizes the advance of the technology in 21century. Everything has two aspects, as we are enjoying the convenience the plastic brings, we got a serious problem: white plastic pollution.

But seldom do we know that the waste plastic is an energy which is just misplaced. They can be recycled again, there is a way can convert the plastic to oil .As a Renewable Energy Equipment corporation , xianxiang doing renewable equipment co,ltd specialized in manufacturing waste plastic to oil recycling equipment which can convert plastic to oil. The latest generation plastic to oil machine we manufacture can process the waste plastic and get the crude oil, conductex, Steel, flammable gas as well. And the latest generation converting plastic to oil machine can produce higher quality oil. The environment of the world is becoming worse and worse because we are concentrating on the development of the economics. Environmental protection is attached more importance nowadays.

As a Renewable Energy Equipment manufacturing company we have the responsibility to protect the environment. In the notion of the environment protection, we keep enhancing our technology to protect the environment we have made great progress in the technology of manufacturing the latest generation machine that can convert the waste plastic to oil. The latest generation converting plastic to oil plant produces no pollution to the environment. And can save much raw material. the latest generation converting plastic to oil machine is environment protection. It is a green technology. The machine can not only protect the environment, but also make much contribution to the environment. The latest generation converting plastic to oil machine has higher quality oil compared with the machine before. What is more the latest generation machine converts plastic to oil has a higher output of oil. So it can create more economics profits.

Good reputation lead to success, we have customers all over the world. We serve them well. Their satisfaction is our engine. The latest generation converting plastic to oil machine is safer and produces little pollution. During the procedure of manufacturing the equipment we control the quality seriously; every accessory is checked by professional worker. We continue pursuiting perfect.

As a corporation we responsible for the nature and the society. we protect the environment by the progress in the technology of manufacturing converting plastic to oil machine. We stick to the notion of sustainable development. In the21 century, we will continue making progress in producing high quality equipment.

| Technical parameter of latest generation plastic to oil machine | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste plastic, waste tyre, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd