Continuous waste tyre pyrolysis plant product introduction

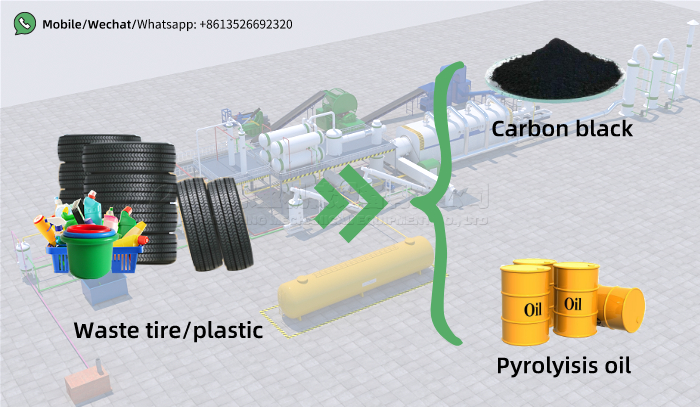

For continuous waste tyre pyrolysis plant, main raw material is waste tire/tyre, which can be easily available in many countries. The raw material is cheaper and can use waste tire, we get out put from waste as fuel oil,carbon black ,steel wire.

Continuous waste tyre pyrolysis plant for fuel oil extraction

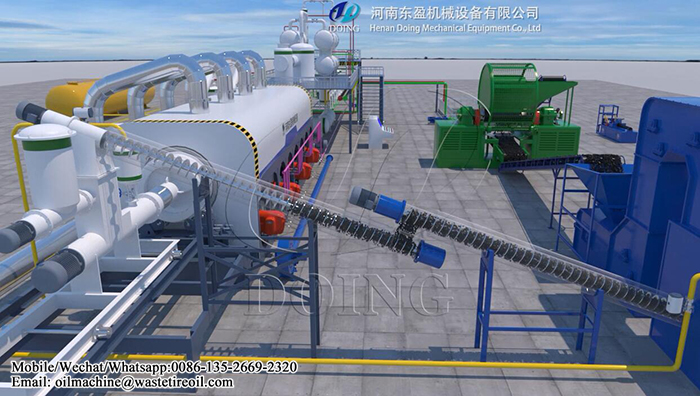

Continuous waste tyre pyrolysis plant working process:

To ensure the continuity of feeding, the tire pre-treatment equipment is necessary, such as tire, it need to be drawn out steel wire first and then broken into small pieces in case of jam during operation. The whole working process is as follows.

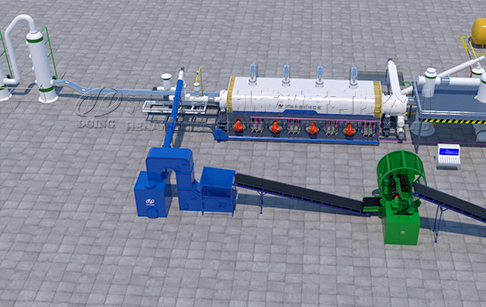

1. The pre-treated tyres will firstly be conveyed to the moving horizontal pyrolysis reactor through feeder system.

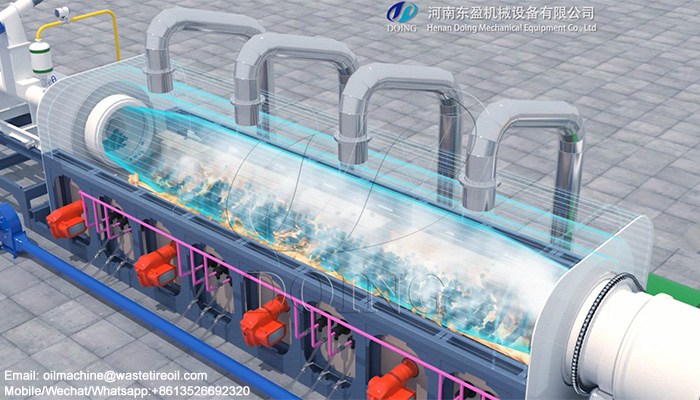

DOING horizontal pyrolysis reactor

2. Then the tyres start to pyrolysis and oil gas will be generated when temperature rises up to 100 degrees.

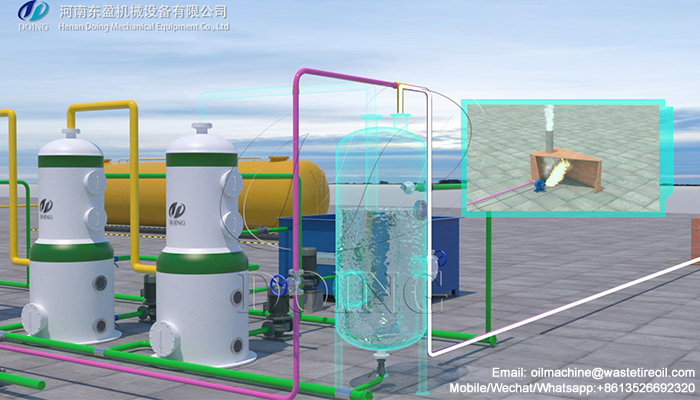

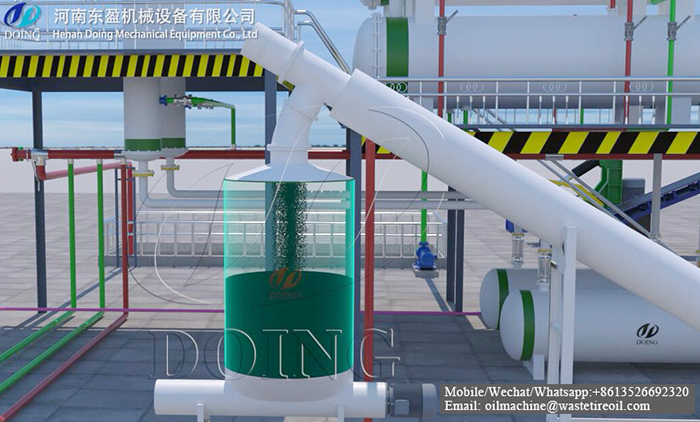

3. Then the oil gas will be cooled down by spray cooling system, it would be liquefied and then go into the oil tank. At the same time, some gas that can not be condensed to oil will come into hot air circulation heating system by secondary fire retardant damper.

Uncondensable gas is recycled to heating reactor

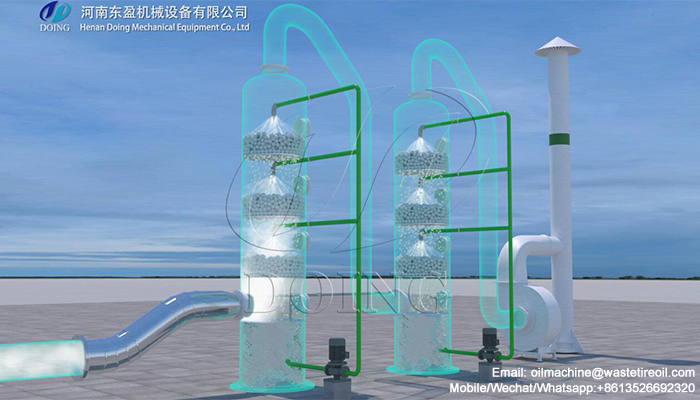

4. Then the gas will be recycled for heating reactor as gas material. The exhaust gas goes to the strong spray dedusting system for removing pollution, then the released gas will be environmental and can be discharged to the air.

5. After finishing oil production, the slag will be discharged automatically by two sealed discharging systems.

Sealed carbon black discharging system

Continuous waste tyre pyrolysis plant advantages:

1. The Continuous waste tyre pyrolysis plant have relatively larger processing capacities of 30-50 MT per day.

2. The Continuous waste tyre pyrolysis plant can achieve feeding of materials and discharging of slags automatically, and can also finish the two steps at the same time, which not only saves time, but also saves fuel.

Automatic feeding system

3. The reactor of the continuous waste tyre pyrolysis plant is stable and not rotary, which makes the temperature rise and pyrolysis react quickly. This special design makes the whole pyrolysis process efficient and can also save much heating materials.

4. The continuous waste tyre pyrolysis plant is equipped with safety device (alarm for over temperature and pressure, auto pressure releasing system, extra gas recycling system, fire fighting devices) and advanced dedusting system (water washing, water spray, ceramic ring adsorption and activated carbon adsorption), which will guarantee safety and no pollution in production.

Dedusting system to remove the smoke produced when heating

5. The continuous waste tyre pyrolysis plant can run for 24 hours a day without a stop and needn’t to be cooled before the second batch.

6. The continuous waste tyre pyrolysis plant adopts new type of condensers which has larger cooling area and better cooling effect. In addition, we can provide special catalyst, which is made from 24 chemicals. The catalyst can not only reduce sulfur content and density of oil, but also improve its flavor and color.

DOING special catalyst to help you get high quality fuel oil

The products of continuous waste tyre pyrolysis plant:

Fuel Oil (45% to 52%)

Fuel oil got from continuous waste tyre pyrolysis plant

The main application of oil products produced by our continuous waste tyre pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes. Such as power plant factory, glass factory, cement factory, ceramic fatory.

Carbon black (30% )

Carbon black produced by continuous waste tyre pyrolysis plant

Carbon black is the main product recycled by Pyrolysis technology. The amount of recycled carbon black is 30% to 35% of the total amount of scrap plastics recycled in the system. Carbon black can applied to electric cable jacketing, black nylon bag, rubber additive

Oil gas (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

Now the continuous waste tyre pyrolysis plant is more and popular with customers. If you want to learn more information about the equipment, feel free to contact us.

| Technical parameter of continuous waste tyre pyrolysis plant | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, waste plastic, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd