Tyre rubber recycling plant product introduction

Tyre rubber recycling plant

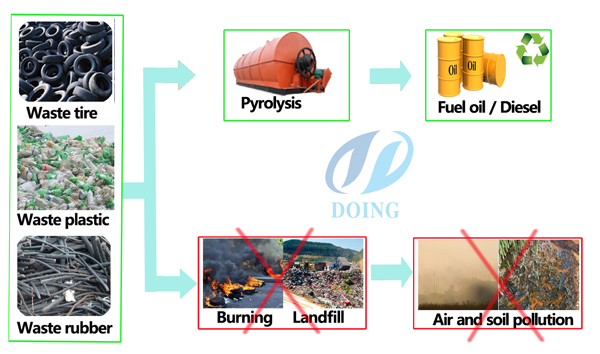

Approximately 1.5 billion tyre rubber are produced globally each year with 300 million in the USA, which will all eventually become waste tires. Waste tyre rubber are excellent candidates for recovery of energy, as well as solid, liquid, and gaseous by-products, via pyrolysis: made predominantly from the petroleum product rubber, they have a high heating value, the tyre rebber recycling plant adopts pyrolysis technology that recycling waste tyre rubber to fuel oil ,carbon black and steel wire.

Tyre rubber recycling plant working process

Tyre rubber recycling plant working process

Pyrolysis involves heating a feedstock to temperatures >400 °C without oxygen in order to volatilize and decompose the feedstock, producing oil, gas, and char . The oil resulting from pyrolysis may be used directly as a fuel, upgraded to a higher quality fuel, or used to produce chemicals. The gases typically consist of C1–C4 hydrocarbons and hydrogen with a high heating content, so that the gases can serve as a fuel for the pyrolysis process. The solid char consists of carbon black filler along with pyrolysis char .

Tyre rubber recycling plant advantage

Tyre rubber recycling plant

1. Every part of the tyre rubber recycling plant are well-designed and some of them has won national patent in China. For example, we add refractory materials outside of the pyrolysis reactor, so as to reduce heat consumption and protect the reactor.

2. We adopt automatic wielding techniques to improve the working efficiency and guarantee the quality of the machine.

3. We use a new heating system combining the advantages of wind-typed heating and direct heating together to improve heating efficiency and save energy.

4. We provide various types with different daily capacities and sizes of the plants. The clients have wide chioces in accordance with their actual production demands and site areas.

5. With high cost performance and energy-saving feature, our waste tyre pyrolysis plant cost is low.

6. Plastic wates, rubber and medical wastes can also convert to fuel oil through this tyre rubber recycling plant.

7. We have safety insurance for the operation. For example we employ 100% avoid-burning system and 100% explosion-proof technology.

8. For our clients, it is profitable because they can earn money from the end products of the tyre rubber recycling plant.

Fuel oil

Fuel oil application

1.Can be used as fuel or sold directly

2.Reprocessed into diesel and gasoline by waste oil distillation plant.

Carbon black

Carbon black application

1.Can be sold directly

2.Reprocessed into high quality carbon by carbon black grinding machine.

3.Make carbon brick by briquetting equipment.

Steel wire

1.Can be sold directly

2.Make steel bloom by hydraulic press-packing

Combustible gas

1.Can be as fuel heating the reactor

| Technical parameter of tyre rubber recycling plant | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, waste plastic, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd