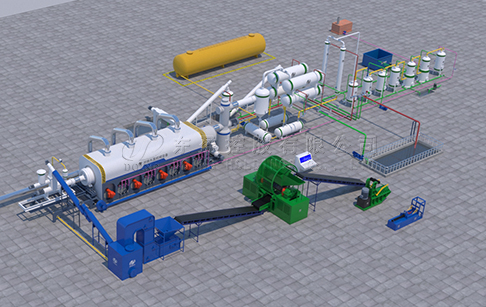

Used tyres into fuel oil recycling equipment product introduction

Used tyres recycling

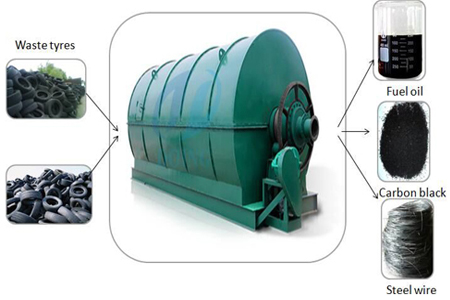

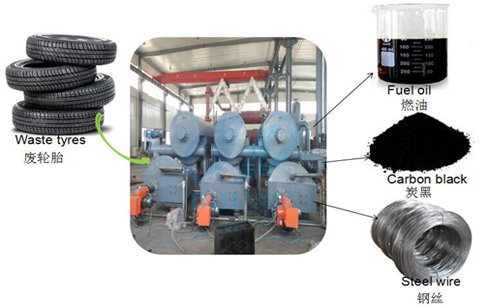

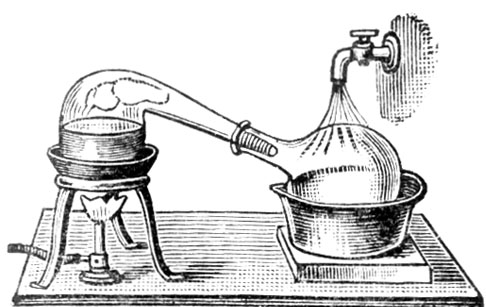

What is pyrolysis:

Plastic and tire pyrolysis involves subjecting plastic and tire

to high temperature of 400 to 450 degree Celsius, in absence of oxygen.

In case of oxygen is present plastic will start burning. During

pyrolysis plastic and tire breaks down into smaller molecules of

pyrolysis oil, pyrolysis gas and carbon black. Like plastic and tire,

pyrolysis end products are also hydrocarbons. Pyrolysis is great way of

recycling waste plastics and tires.

Pyrolysis reaction simulation

Given below are benefits ofused plastic and tyres pyrolysis:

1.Torecycle the used tyres/plastic into usable fuel.

2.To recover the wastes into renewable energy source.

3. To eliminate the pollution of used plastic/tyre.

4. To convert waste into energy.

5.Environment protection.

Fina products of used tyres into fuel oil recycling equipment can have more applications:

| Items | Application | Sales Market |

| Pyrolysis oil | 1. Add it into heavy oil generator to produce electricity. 2. Used as heating material. 3. Sell it into oil refining factory to further process it. | Ceramic factory, glass factory, electric power factory, steel making factory, boiler factory…etc. |

| Carbon black | 1. Deep process it into N220, N330 Carbon black. 2. Make it into pellet or briquette for burning 3. Further process it into color master batch as basic material to make pipes, cable jacket…etc. | Coal briquette factory, plastic factory, cable factory, etc. |

| Waste gas | Recycled into fire furnace to heat reactor to save fuel material. | |

Oil rate of general Rubbers:

| Big truck tires | 45% |

| Small car tire and bike tire | about 35% |

| Rubber electric cable and shoe sole | about 35% |

| Mixture shoe sole | about 30% |

| Sport shoes | 20%-30% |

| Waste chemical fiber carpet | more than 30% |

| PMMA | 40% |

| Technical parameter of used tyres into fuel oil recycling equipment | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste plastic, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd