waste lubricant engine oil oil to diesel fuel oil refining plant product introduction

Waste lubricant engine oil oil to diesel fuel oil refining plant

Waste lubricant engine oil is one important alternative fuel source proved to be the best substitutes for existing petrofuel, since waste lubricant engine oil from waste lubricant engine oil to diesel fuel oil plant represent more than 60% of waste lubricant engine oil. Therefore, waste lubricant engine oil is one of the most abundant pollutant residues that are generated nowadays, reaching the value of 24 million metric tonnes per year.

In recent years, recycling of the waste lubricant engine oil and utilizing of the products as fuels have become important topics for researchers. Most of the waste lubricant engine oil is generally obtained from petroleum resources. This kind of oil currently account for about 97% of the total lubricant production. However, these oils become waste lubricant engine oil harmful for environment after a certain time period. Recycling of the waste lubricant engine oil by purifying and converting them into fuels is very important in terms of protection of the environment.

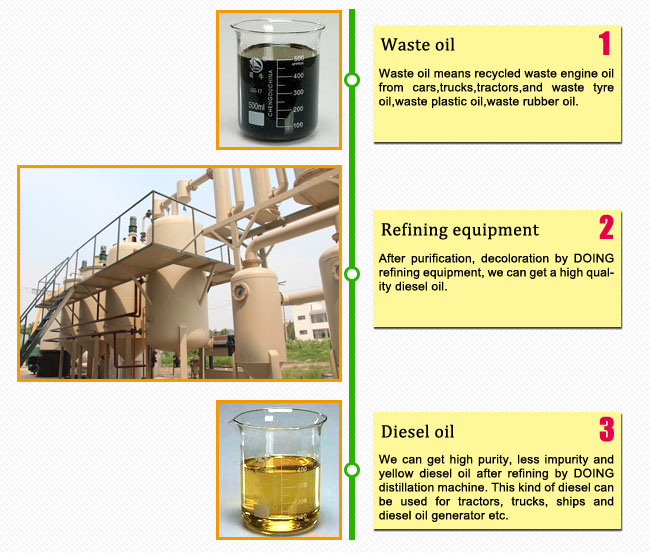

Waste lubricant engine oil

After waste lubricant engine oil is converted into fuels, they can be used as fuels in internal combustion engines. In recycling process, waste lubricant engine oil is exposed to various processes, and then used as fuel or they are converted into various chemicals in order to minimize the harmful effects of these wastes.

Millions of tons of waste lubricant engine oil is disposed through dumping on the ground or in water, land filling, or non-energy-recovery. The used or waste lubricant engine oil can be refined and treated to produce diesel fuel stock. On the other hand, the waste lubricant engine oil pose an environmental hazard due to both their metal content and other contaminants.

The high-volume waste lubricant engine oil can be turned into valuable fuel products by refining and treating processes which is a good way to dispose the waste lubricant engine oil.

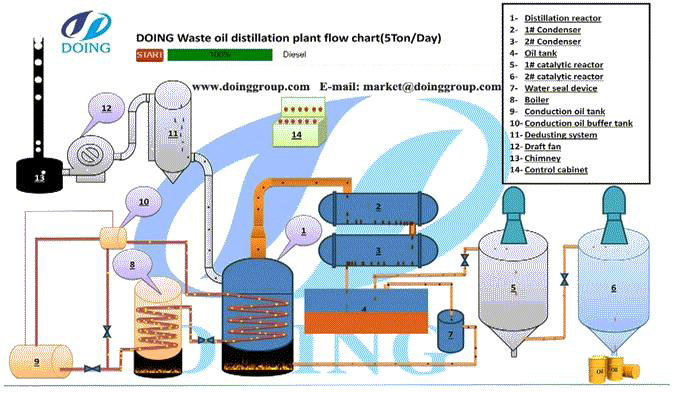

Now, let's see how the waste oil refining plant works. It mainly include four steps:

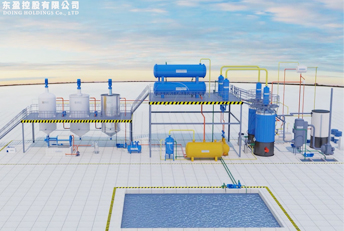

The working process of waste oil refining plant

1.Pump used motor oil to distillation reactor for further process

2.Heat the liquid oil through the heat conduction oil to make the liquid waste oil become oil gas

3.Cooling the oil gas through a cooling pipe to get distillation oil

4.Filtering the distillation oil through the solid catalyst, then we can collect the final products.

Utilization of the diesel fuel oil produced from the waste lubricant engine oil, and blending of the produced fuels with gasoline or turpentine decrease consumption of petroleum based fuels, protecting environment from toxic and hazardous chemicals. It also saves of foreign exchange, reduces greenhouse gas emissions and enhances regional development especially in developing countries.

| Technical parameter of waste lubricant engine oil oil to diesel fuel oil refining plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | waste tyre, waste plastic, waste rubber, |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd