Used tyre oil to diesel fuel oil refining plant product introduction

Product specification of used tyre oil to diesel fuel oil refining plant:

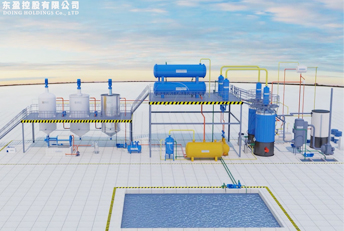

Our used tyre oil to diesel fuel oil refining plant is specially made mainly as the auxiliary equipment of our waste tyre/plastic pyrolysis plant. It can refine tyre fuel oil and plastic fuel oil got from the pyrolysis plant into diesel fuel oil.

However, Except tyre oil and plastic oil, this used tyre oil to diesel fuel oil refining plant can also refine waste motor/engine oil into diesel. This diesel oil can be used for boilers, trucks, generators, and low speed engine like digging machine/road roller/loading machine and so on.

The normal processing capacity for our used tyre oil to diesel fuel oil refining plant includes 3T/D, 5T/D ,10T/D and 20T/D.

Used tyre oil to diesel fuel oil refining plant

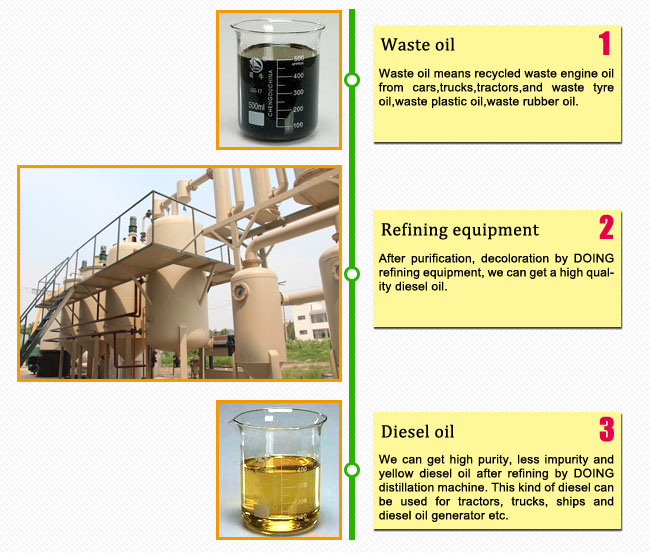

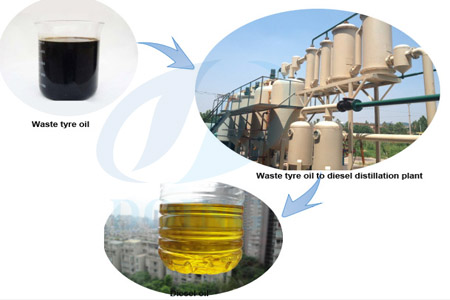

Feedstock& product of usedtyre oil to diesel fuel oil refining plant:

The feedstock can be tyre pyrolysis oil, plastic pyrolysis oil, waste engine oil, etc, the final product will be diesel oil

Working process of used tyre oil to diesel fuel oil refining plant:

1.Put tyre oil/plastic oil/engine oil into distillation reactor with oil pump

2.Heating system works to heat waste oil over 170℃

3.Distillation oil gas produced and cooling down to pure distillation oil by condensers

4. After distillation, the distillation oil is pumped into odor-removal tank where catalysts used to remove the smell

5. Then oil go into color-removal tank for de-coloring with the special catalysts

6. Finally, you can get about 85% pure diesel oil.

Main feature of used tyre oil to diesel fuel oil refining plant:

Used tyre oil to diesel fuel oil refining plant

New tech used tyre oil to diesel fuel oil refining plant is always known for its high working efficiency, high oil output and high oil quality since its first day appearing in the market.

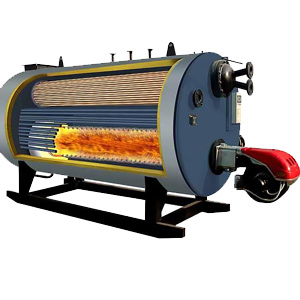

Why used tyre oil to diesel fuel oil refining plant is the new tech? That is because used tyre oil to diesel fuel oil refining plant has the revolutionary changes on the design of distillation reactor and the heating method. Used tyre oil to diesel fuel oil refining plant adopts vertical design distillation reactor and indirect heating by heating oil boiler, rather than the traditional horizontal design distillation reactor heated with open fire. The temperature of heating oil can reach 400℃,the refining process can be finished very fast with the heat from the heating oil, meanwhile indirect heating can greatly prolong the reactor life. The traditional waste tyre to diesel refining machine heated directly by open fire, and it will take very long time to finish the refining process and since it uses open fire heating, the reactor body will have short life time, besides, the distillation reactor is horizontal design, it is not easy to do the residue slagging. Anyway , used tyre oil to diesel fuel oil refining plant has many obvious advantages over the traditional one.

Technical parameters fo used tyre oil to diesel fuel oil refining plant:

| Technical parameter of plastic to diesel oil distillation | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

| Technical parameter of used tyre oil to diesel fuel oil refining plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | waste tyre, waste plastic, waste rubber, |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd