Plastic to diesel oil distillation pyrolysis plant product introduction

Product introduction of plastic to diesel oil distillation pyrolysis plant:

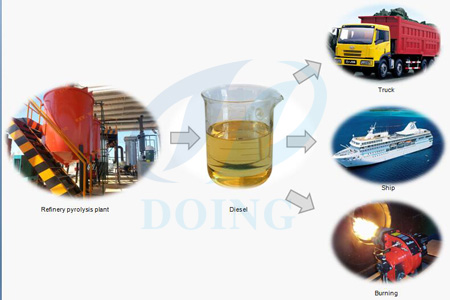

Plastic to diesel oil distillation pyrolysis plant can convert plastic fuel oil into plastic diesel oil. The plastic diesel oil is a very good diesel which is very close to common diesel. It can be used in diesel generator, tractors, trucks, agricultural vehicles etc.

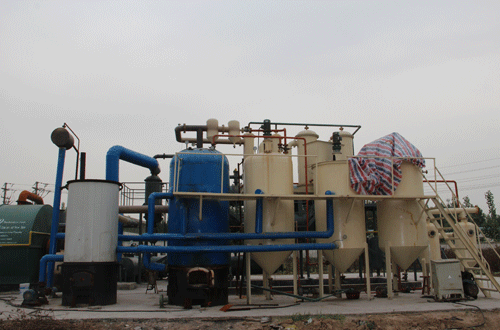

Plastic to diesel oil distillation pyrolysis plant

Feedstock & product of plastic to diesel distillation machine:

Plastic fuel oil will be pumped into the vertical reactor of plastic to diesel distillation machine. After finished whole processing, the final products are 85% diesel and the remaining is bitumen.

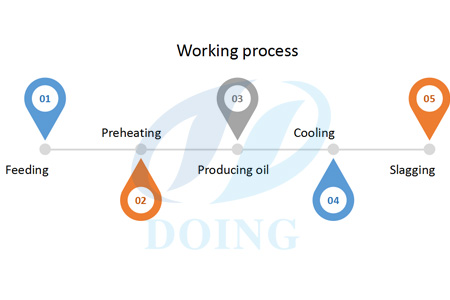

Working process of plastic to diesel distillation machine:

Plastic to diesel oil distillation pyrolysis plant

Plastic fuel oil will be heated into oil gas with indirect heating. Then oil gas will be cooled into diesel. With the processing of color and odor removal system, diesel quality will be improved a lot.

Main features of plastic to diesel oil distillation pyrolysis plant:

1.Fast.

The unique fast heating system is especially designed for shorten working time.

In market, mostly are horizontal reactor or old design for plastic to diesel distillation machine which take about 3-5days to finish one batch.

2.Easy slagging

Vertical reactor make slagging from bottom automatically and fast.

3.Energy saving

Fast heating system keep temperature even after slagging and you can use for next batch so is energy saving.

4.Safe

Strict quality control system and professional safety devices guarantee our plastic to diesel distillation machine running safely and win a good reputation from customers.

5.Environmental friendly

Professional dedusting systems ensure our plastic to diesel distillation machine runs zero pollution.

| Technical parameter of plastic to diesel oil distillation pyrolysis plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | waste tyre, waste plastic, waste rubber, |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd