Continuous waste tyre pyrolysis plant product introduction

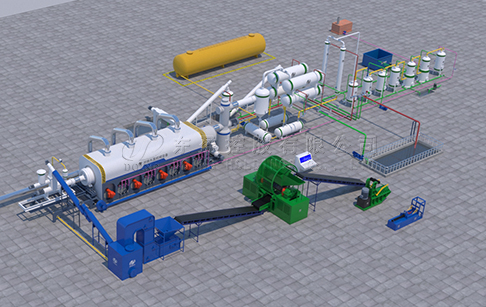

Continuous waste tyre pyrolysis plant

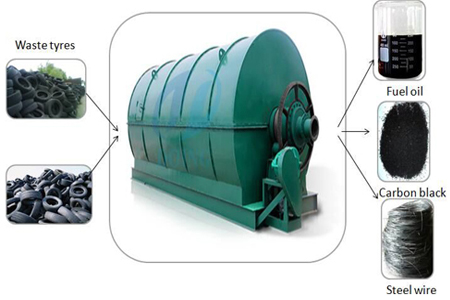

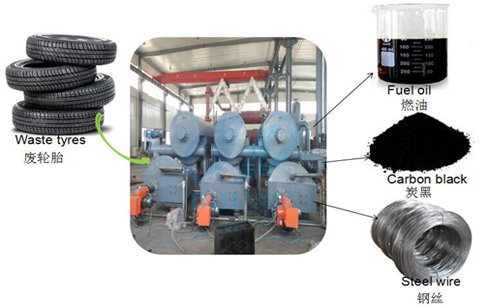

Continuous waste tyre pyrolysis plant of Doing is to convert waste tyre into fuel and energy .The material of continuous waste tyre pyrolysis plant is waste tyres ,waste plastics ,waste rubber and so on.The main feature of fully continuous waste tyre pyrolysis plant is feeding in every second and minute,automatic ejecting wastes residue,fuel product day and night,without pollution ,high effeciency.The final product of continuous waste tyre pyrolysis plant is fuel oil,carbon black,steel wire .All the products are used widely, in hotels,restaurants,bathing centers,power plants,engines,chemical sector etc.so you can sell them directly.

Continuous waste tyre pyrolysis plant advantage

Well water dedusting system can avoid black smoke.

2. The exhaust gas will be recycled for heating reactor, no gas pollution

3. Every junction of the reactor is in good sealing situation with professional sealing material.

Long service life:

1. Material: Q345R special steel plate, thickness 16mm

2. Welding: Automatic welding machine with heat treatment and x-ray detection will prolong the service life of reactor to the max.

3. The service life of the reactor will be approximately 8 years

Energy saving:

1. Well sealing for heating system, no gas leak and saving fuel.

2. The exhaust gas will be recycled for reactor heating.

Continuous waste tyre pyrolysis plant final product and application

Final product and application of continuous waste tyre pyrolysis plant

Continuous waste tyre pyrolysis plant tech data

| Raw material | Waste tyres ,waste plastic ,waste rubber ,waste mainery oil |

| Capacity | 6T 8T 10T |

| Working pressure | Ordinary pressure |

| Cooling ways | Water |

| Operation type | fully automatic continuous |

| Heating means | Hot blow ,flammable,gas ,coal and oil |

| Technical parameter of continuous waste tyre pyrolysis plant | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, waste plastic, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd