Waste recycling machine product introduction

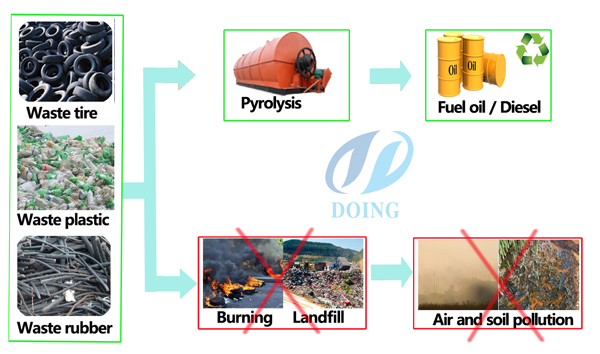

With the rapid development of the economics and society the rubbish are also increasing at a very fast speed. We faced more and more serious pollution such as waste plastics, waste tyres and so on. As the increasing stand of our life, we have a high stand for the environment we live we need clean air, green water. On the other hand we are consuming more and more limited energy such as the diesel in the car, the coal we used to generate heat and so on. We need the energy urge to relieve the pressure of increasing consuming speed. What is more we are facing the solid waste such as the dumped waste plastic, dumped waste tyre, and so on. If burned the waste plastic will generate waste gas to air, if dumped they will occupy the land we live. The discarded waste tyres which exposed to the environment for a long time will breed virus-carrying mosquitoes. It is harmful to both the environment and humans'health.

So to achieve the sustainable development the recycling method is becoming the best solution to solve the problem. For the waste plastic and waste tyre .we can convert the waste tyre/plastic to oil for fuel. The waste plastic/tyre recycling machine is to convert the waste plastic or waste tyre to fuel oil. The waste tyre/plastic recycling machine can not only deal with the waste plastic or waste tyre but also can generate fuel oil which will relieve the energy pressure on great extent. So let us introduce the waste tyre/plastic recycling machinein detail:

Advantages of waste tyre/plastic recycling plant:

1. Environmental friendly: the waste tyre/plastic recyclinig plant will convert the waste tyre/plastic to fuel oil. The process is clean without any pollution to the environment.

2. Energy saving: the plant is designed to use little external energy. The natural gas is only used when the plant starts. Once the pyrolysis plant is running the pyrolysis plant will use its own off-gas to heat the reactor. What is more, the plant will generate energy itself.

3. Profitable: For the cost of the waste tyre/plastic recycling machinethey are: the price of waste tyre or waste plastic, the electricity (the electricity used in the process is very little), the fuel used to heat the reactor (It is also very little).The final product of waste tyre recycling plant: fuel oil, carbon black, steel wire, oil gas. The oil yield rate: fuel oil: 40%-45%, carbon black: 30%-35%, steel wire: 10%-15% oil gas: 10%.The price of the fuel oil will be much higher than the raw material.

We Xinxiang doing renewable equipment co.ltd are the professional supplier and manufacturer of waste plastic/tyre recycling plant. With years'development and research we have mature technology to manufacture high quality pyrolysis plant. Established ourselves as one of the reputed suppliers of the waste plastic recycling pyrolysis plant, we have product ranges from10T to higher capacity. Reasonable price, huge reputation, perfect service. We have achieved this status by total years development and research.

| Technical parameter of waste recycling machine | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, waste plastic, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd