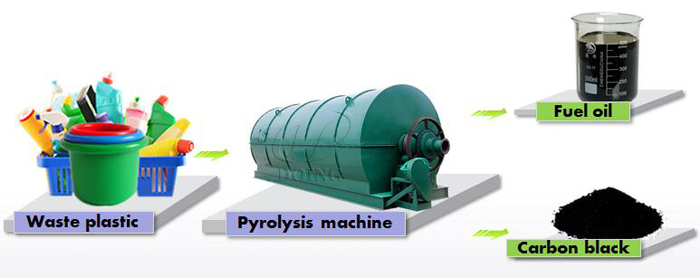

Convert waste platic to fuel oil plant product introduction

Convert waste plastic to fuel oil plant

The waste plastic now has become a serious pollution to our environment; always they are dumped or land filled. Thus will pollute the environment destroy the land.The plastic to fuel oil plan is an environmental friendly plant to convert the waste plastic to fuel oil.

Waste plastic to oil plant is widely applied worldwide. It will generate no pollution to the environment. The advantages of the waste plastic to fuel oil plant:

Energy saving:

1. Our plant is designed to use no external energy to heat the reactor. The natural gas is only used on the beginning when the plant starts. Once the machine is running the plant will use its own gas to heat the reactor. The waste gas will be recycled back to heat the reactor.

2. We have auto-welding technology to weld the reactor. The technology guarantees the sealing of the reactor thus improving the burning efficient and avoids blast.

3. The water used to cool the oil gas is non-contact with the process itself, keeping the water clean and uncontaminated.

Safe:

1. The vacuum system will guarantee the safety when plastic to fuel oil plant is running.The vacuum will prevent the oil gas from leaking.

2. The auto-welding technologies guarantee the sealing of the reactor. The technology makes the reactor seal well. Avoid accident.

3. It is dangerous to burn exhaust gas (C1 TO C4) without any safety equipments. During the process of converting waste plastic to fuel oil the waste gas will be transferred through the safety device first. Thus will guarantee the safety of burning the recycled off gas.

Environmental friendly:

We have well dedusting system to remove the ash to guarantee the lower commission to the environment.

The automatic carbon black discharging system will discharge the carbon black automatically which is seen as a solid waste. The carbon black is also a material of energy.

We have waste water disposal system to deal with the waste water. The water finally discharged is clean.

| Technical parameter of convert waste platic to fuel oil plant | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste plastic, waste tyre, waste rubber, | ||

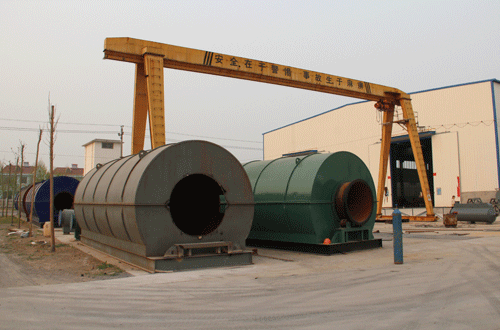

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd