Used plastic to oil recycling machine product introduction

Used plastic to oil recycling machine

Plastic products has been used widely, and waste plastic can be seen in streets, landfills, and oceans. It has seriously affected our environment on two aspects, such as visual pollution and potential hazards. Visual pollution means that aesthetic perception on living city affected by used plastic in everywhere. The accumulation of plastic scrap creates unsightly pollution, while the long decomposition time of plastics contributes to soil and water contamination. Thankfully, used plastic to oil recycling machine has supplied a new practical solution on disposal of waste plastic.

Used plastic to oil recycling machine

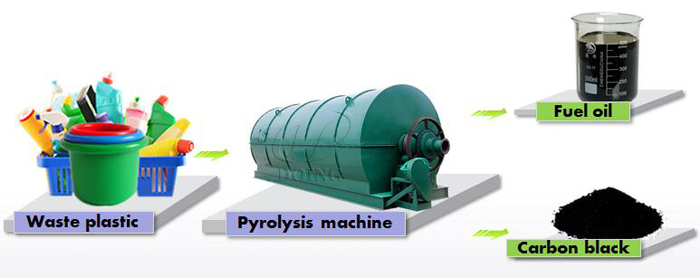

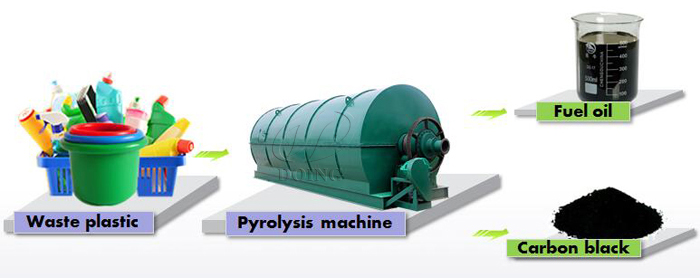

The used plastic to oil recycling machine can recycle and convert waste plastic into valuable fuel oil, syn-gas and carbon black. Nowadays, Used plastic to oil recycling machine uses pyrolysis technology. Pyrolysis is a chemical process, converting high- molecular compound into other low molecular compound by heat energy. This method offers a sustainable approach to dealing with the global plastic waste problem by converting waste plastics into renewable energy sources.

Used plastic to oil recycling machine is pyrogenic decomposition of waste plastic, depolymerizing agent and catalyst (optional); then macromolecule waste plastic will be converted into micromolecule fuel oil. Doing group used plastic to oil recycling machine takes full advantage of this technology, operates through a streamlined and efficient process, ensuring optimal resource recovery and minimal environmental impact.

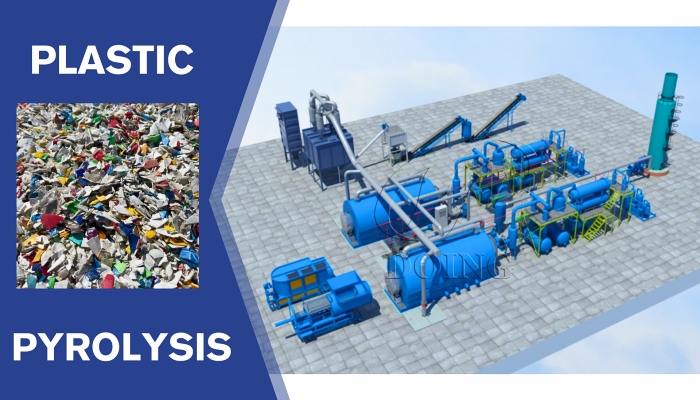

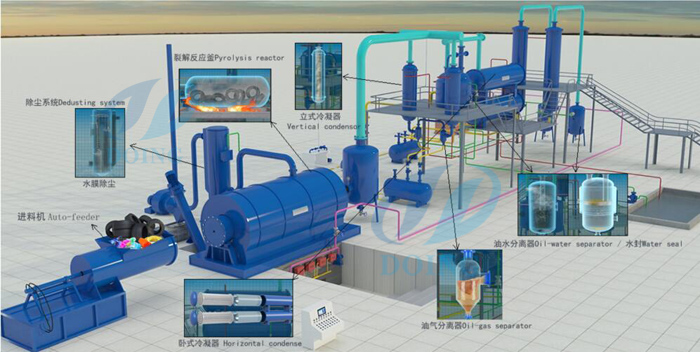

Used plastic to oil recycling machine working process:

Used plastic to oil recycling machine working process

1.Put waste plastic raw materials into pyrolysis reactor by auto-feeder(optional), then heat the reactor with any one of the following fuel materials: coal, wood, natural gas, oil. Do not stop heating the reactor, when the temperature reaches nearly 250 degree Celsius, waste plastic will be transferred to oil gas.

2. The liquid oil will be cooled by professional condenser from oil gas and then collected by oil tank. Besides that, the syn-gas which can not be cooled in normal pressure will be recycled to heat the reactor. In this way, you can not only saving energy, but also protecting environment.

3. Smoke produced by processing the plastics can achieve national emission standard through dual desulfurization and dusting removal device.

4. After you get crude oil(plastic pyrolysis oil), the temperature will be low, at this time, carbon black will be discharged automatically. Last, when the temperature falls to 50 degree Celsius(only for batches, the semi-continuous and fully continuous used plastic to oil recycling machines don't need to cool down batch by batch). After all these steps, you can start another batch.

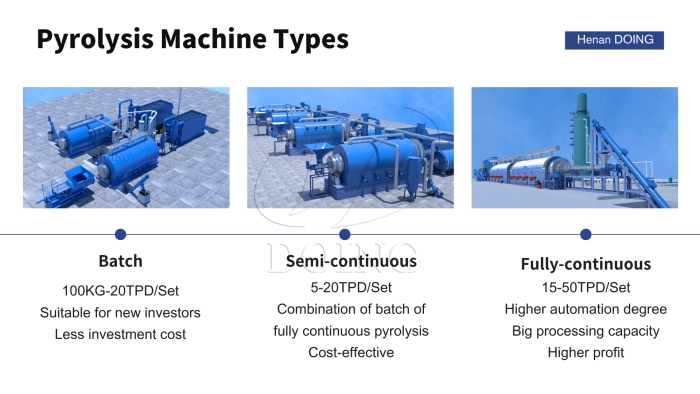

Used plastic oil recycling pyrolysis machine types

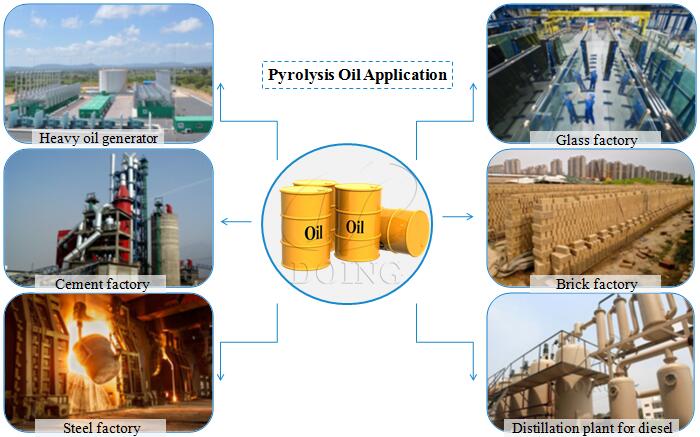

Final Product Applications

Fuel Oil (20% to 80%) : The main oil product produced by our used plastic to oil recycling machine is the plastic pyrolysis fuel oil, which is wide used for industrial and commercial heating purposes, such as boilers, cement/steel/cement/glas/china/aluminum alloy manufacturers and other companies that need to find alternative heating fuels. The regenerated plastic pyrolysis oil can be further refined into diesel, which can be used in trucks, heavy machinery, ships, tractors, and so on.

Plastic pyrolysis fuel oil application

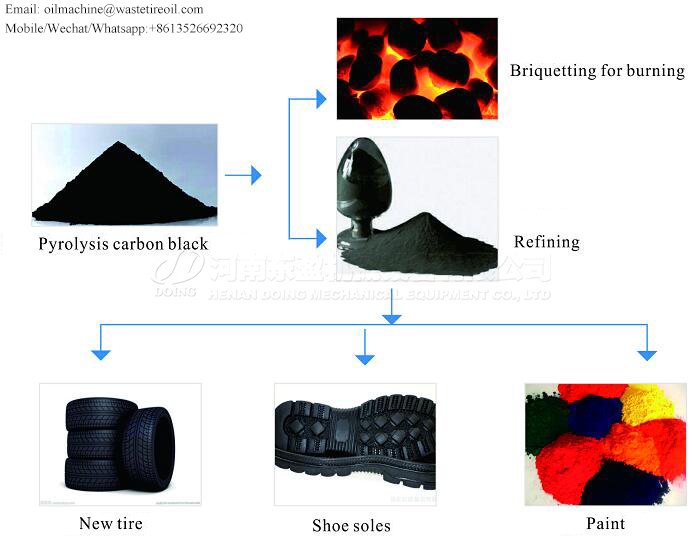

Carbon Black Powder (15% to 60%): The second product of used plastic to oil recycling machine is carbon black. The quantity of carbon black is about 10% to 60% according to plastic quality. The use of carbon black is as a chemical strengthener in rubber and coloring agent in pigment industries. This carbon black price is very competitive compare to petroleum carbon black, so our pyrolysis carbon black is good option in stead of petroleum carbon black.

Plastic pyrolysis carbon black application

Non-condensable Syn-Gas (5% to 15%): Reused within the system to enhance energy efficiency; any excess may be flared or utilized for auxiliary needs in compliance with local regulations.

Specifications and Parameters of Used Plastic to Oil Recycling Pyrolysis Equipment

Raw Material: Waste plastics like Polyethylene (PE), Polystyrene (PS), Polypropylene (PP), mixed plastic waste, medical plastic waste, composite alimunim plastic materials, and other non-chlorinated plastics(PVC and PET isn't suitable for pyrolysis).

Daily Output Capacity: Ranges from 100Kg/Batch to 50Tons/day per set(customizable by model and feedstock)

Feeding system: automatic feeder with material pre-treatment and sorting options

Heating Fuel Materials: coal, wood, natural gas, or oil burner

Temperature Range: 250°C to 500°C(adjustable within safe limits)

Automation: PLC control with HMI, remote monitoring, auto-feeding and auto-discharging

Footprint and installation: modular, skid-mounted for rapid deployment, or common options, covering 15-900㎡

Advantages of Plastic Pyrolysis as a Recycling Method

The Used Plastic to Oil Recycling Machine offers numerous benefits, both economically and environmentally:

Eco-friendly Recycling: The pyrolysis process reduces the burden of plastic waste on landfills and the environment. By converting waste plastics into usable products, fuel oil, carbon black, syn-gas, we can help reduce the negative impact of plastic pollution.

Convert used plastic into fuel oil and carbon black

Energy Conservation: By recycling exhaust gases to fuel the reactor, the process is energy-efficient and reduces the need for external fuel sources.

High-Value Byproducts: Fuel oil and carbon black are both valuable products, making the entire process not only environmentally friendly but also economically viable for businesses.

Sustainable Alternative: This recycling method provides a renewable energy source that can replace traditional fossil fuels, contributing to a more sustainable future.

Circular economy support: Reduces landfill burden and extends the life cycle of plastic materials by closing the loop through energy recovery and material regeneration.

Why Choose DOING Used Plastic to Oil Recycling Pyrolysis Solution?

Customizable and scalable: Multiple model types(skid-mounted type, batch type, semi-continuous type, fully continuous automtic type) and diverse sizes to fit your throughput requirements, space constraints, and capital plans.

Comprehensive support: Installation, operator training, spare parts, and ongoing technical assistance to maximize productivity and minimize downtime.

Regulatory alignment: Designed to help you comply with applicable environmental, safety, and product-handling standards.

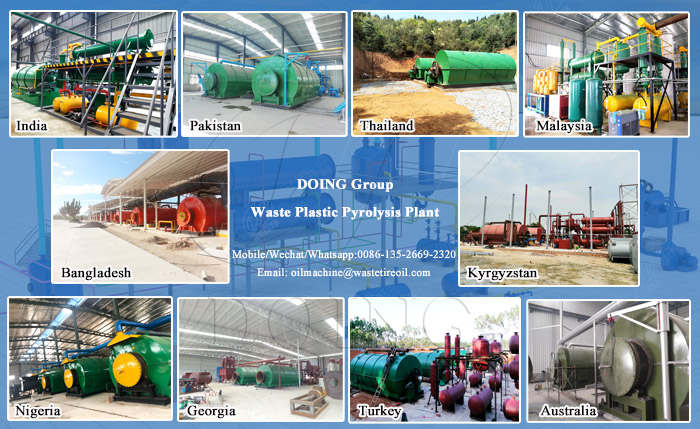

Successful Project Cases: Henan Doing Company has exported machines all over the world, covering 100+ countries, such as America(USA), Canada, Poland, China, India, Russia, Belgium, Korea, Brazil, Spain, Venezuela, South Africa, Nigeria, Indonesia, Fiji, Italy, United Kingdom, Thailand, Vietnam, Kazakhstan, etc. We have many successful waste to oil energy recycling pyrolysis machine running sites for your reference.

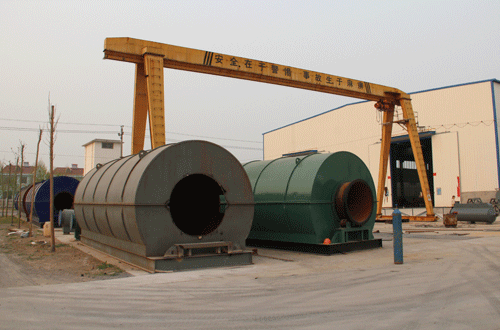

Used plastic to oil recycling machine in customer factory

If you‘re evaluating a practical, high-performance solution for plastic waste management, DOING Brand Used Plastic to Oil Recycling Machine can be customized to your capacity, feedstock mix, and regulatory requirements. Contact us for a consultations, a detailed proposal, or a quotation.

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd