Waste oil to diesel distillation plant product introduction

The Waste Oil to Diesel Distillation Plant is an innovative waste oil recycling solution, which is designed to refine a wide range of waste oils, including used engine motor oils, tire plastic pyrolysis oils(crude oil), used engine oils, and heavy mazut fuel, converting them into cleaner, higher quality diesel oil suitable for use in heavy machinery engines and generators. Waste oil to diesel distillation plant not only brings more substantial financial benefits for us, but also protects the environment by reducing pollution.

Waste oil to diesel distillation plant designed by DOING

Why Invest in a Waste Oil to Diesel Distillation Plant?

If someone asks what the most valuable resource in the world is, oil resource is the best answer without doubt. The value of oil lies in its critical role as a fuel source for transportation, industry, and energy production. That is means person who owns oil resource will owns wealth.

This inherent value has driven innovation, leading to the development of waste tyre/plasticpyrolysis plants that convert discarded materials into fuel oil. However, the purity and color of pyrolytic oil often fall short of the stringent standards required for direct use in vehicles. Simultaneously, a massive volume of waste oil emerges annually from the increasing number of vehicles and industrial activities – including waste motor oil, used engine oil, lubricating oil, and even heavy mazut fuel. This presents both an environmental challenge and a significant economic opportunity. This is precisely why DOING Waste Oil to Diesel Distillation Plant is emerged. It is not merely an industrial waste oil recycling machine; it's a key enabler of a profitable and sustainable future.

Establishing a waste oil recycling and distillation business offers substantial profit margins, turning potential environmental liabilities into valuable assets:

①Environmental benefits: The environment can be protected from pollutants caused by waste oil dumping or combustion plants by using this waste oil to diesel plant.

②Resource efficiency: The current market for recovered diesel is robust, with prices often competitive with conventional diesel, especially when considering the low cost of raw materials. It converts low-value waste fossil streams into diesel fuel, creating new revenue opportunities.

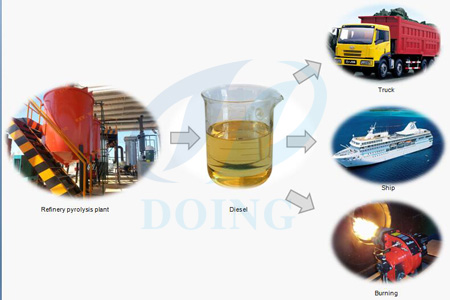

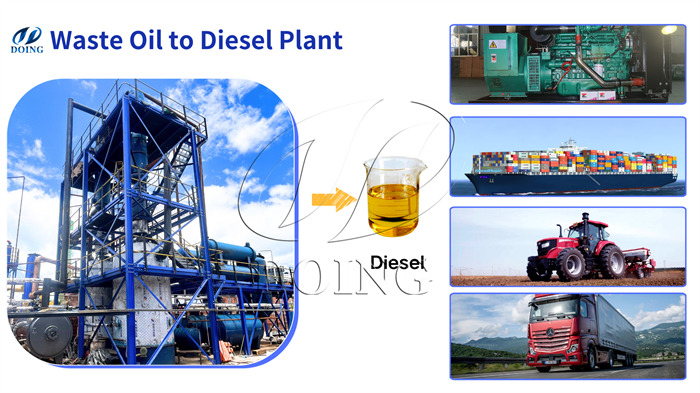

③Market demand: The refined diesel fuel produced meets the required standards for use in heavy machinery engines, diesel generators, tractors, trucks, ships, and other heating boilers. By upgrading waste oils, you unlock valuable products and create a sustainable business model.

Waste oil recycled diesel applications

Waste Oil to Diesel Distillation Plant Working Process

Our advanced Waste Oil to Diesel Distillation Plant is engineered to process versatile oily waste materials, with a superior used oil to diesel conversion rate, about 80-85%. About two to four people are only required to operate on this machine. It operates under low energy consumption rate.

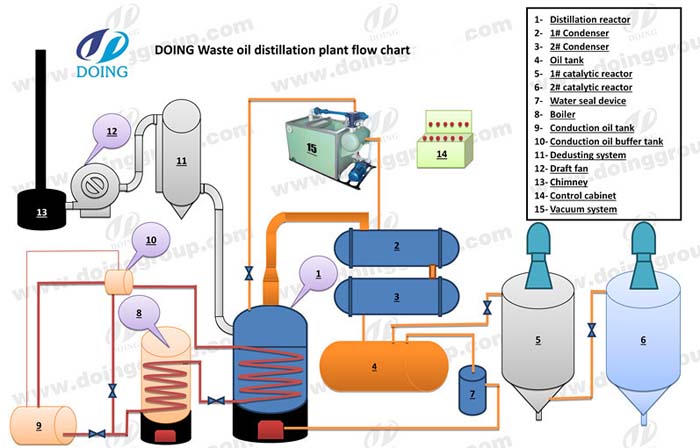

The whole waste oil to diesel distillation process involves heating, vaporizing, and purifying waste oils through a combination of thermal and chemical treatments. Here’s a step-by-step overview:

Waste oil to diesel distillation plant working process

1. Preparation of Waste Oil: Collect various waste oils, such as waste tire oil, plastic oil, used engine oil, and heavy mazut fuel, are collected and prepared for the distillation process. The oil is filtered to remove any large debris or impurities.

2. Heating and Distillation: The prepared waste oil is heated to a high temperature in a distillation reactor unit. As the oil heats up, it begins to break down into its constituent components. During this phase, volatile compounds are separated from heavier substances.

3. Cooling: The distillation unit cools the vapors, causing them to condense back into liquid form. This phase helps segregate the different fractions of the oil, separating the lighter fractions (which form diesel) from the heavier fractions (which can be further processed or used as fuel for the distillation process itself).

4. Catalytic Treatment: we offer two distinct yet advanced technologies to cater to diverse operational needs and investment levels:

A: Liquid Catalyst Technology: Acid and alkali solutions are used to remove impurities and improve fuel quality.

B: Solid Catalyst Technology: Our proprietary solid catalyst system offers higher automation, faster reaction times, and greater efficiency—ideal for continuous, large-scale operations.

Waste oil to diesel catalytic distillation technologies

5. Clay Bleaching Purification: In this final polishing step, the diesel passes through a special decolorization system using activated clay. This process removes any remaining pigments and impurities, resulting in a clear, bright-yellow diesel that commands higher market prices.

Selling unrefined waste oil or dumping waste oil to disposal center offers minimal returns. In contrast, converting that same oil into refined diesel multiplies its value significantly. Don’t let valuable resources go to waste.

If you are evaluating a waste oil to diesel distillation projector planning to expand your existing plant, reach out for a free, confidential consultation. Our engineers will review your feedstock profile, target diesel yield, and local regulatory requirements, then propose an optimized solution with a clear path to profitability.

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd