Waste lube oil distillation plant product introduction

Lube oil mainly means the waste lube oil generated from all kinds of machinery, vehicles and ships. We also call it waste engine oil. It’s caused of the lube oil used in all kinds of engines after long time use. Due to the outside pollution, the lube oil will generate large quantity of gum and oxide, which will reduce the friction control, wear resistance, cooling, sealing and vibration attenuation of the lube oil, which have to be changed by new lube oil.

Generation of lube oil

Due to the widely use of lube oil, like in China, the waste engine oil generated from vihicles and ships is more than 4 million tons waste oil per month. In the early days, most waste engine oil are just poured aways or directly burned. This not only waste a lot of resource, also cause very serious environmental pollution. For the countries lack of oil, this is a very big consumption for their oil storage, thus to cause high oil price, resource shortage and environmental pressure. And the overload oil importation will endanger the social and economic development and national security. Thus what we do with the used oil plays an important role in balancing our desire for convenient transportation with our desire for a clean and healthy environment today and for future generations.We are all familiar with recycling newspapers, aluminum cans, glass and plastic bottles, but you may not be aware of the efforts of the petroleum industry and other groups to promote used motor oil recycling: providing convenient collection sites for the purpose of keeping used motor oil out of our waterways and ground water supplies and getting used oil into the recycling system.

If you recycle just two gallons of used oil it can generate enough electricity to run the average household for almost 24 hours.

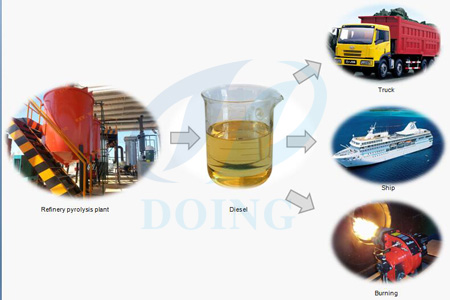

Waste oil to diesel

We DOING Company is a professional manufacturer specialized in waste recycling machinery. The waste or used oil recycling machine is one of our main products. The waste oil recycling machine, we usually call it oil distillation machine, which can refine the waste or used oil to clean fuel for further use through a distillation and chemical process.

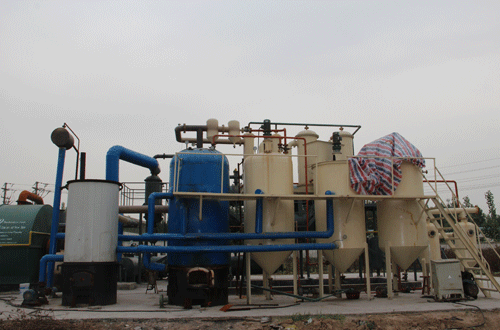

Waste lube oil distillation plant

Raw materials and end products:

Feedstock: waste engine oil/ lube oil/ motor oil

Products: 85% diesel, 10% asphalt, 5% water and other impurities.

Working process of waste lube oil distillation plant :1. Prepare waste engine oil

2. Heating for distillation

3. Cooling

4. Chemical process for cleaning the distillation oil

5. Collect final diesel product

Main features of Waste lube oil distillation plant:

Ourcrude oil distillation plant mainly has 2 advantages.

1. Vertical design: which can make fast and automatic discharge for asphalt residues;

2. Coil heater with conduction oil heating method:

Coil heater can make heating evenly and fast, it can keep processing 3 batches oil in 2 days without stop;

Conduction oil is for recycle use, which can save a lot of heating fuel for you.Technical Parameters of waste lube oil distillation plant:

| Technical Parameters of waste lube oil distillation plant | ||

| NO. | Items | Contents |

| 1 | Capacity | 5T/D, 10T/D, 15T/D, 20T/D |

| 2 | Raw material | Tire/plastic pyrolysis oil, waste engine oil |

| 3 | Structural form | Vertical |

| 4 | Outputs | Diesel, asphalt |

| 5 | Diesel yield | 80-85% |

| 6 | Operating pressure | Normal |

| 7 | Material of Reactor | Q245R boiler plate |

| 8 | Thickness of Reactor | 16mm |

| 9 | Safety standard | Pressure vessel standard |

| 10 | Total power | 24.5KW |

| 11 | Mode of cooling | Recycled water cooling |

| 12 | Required water | 40m3 for recycle use |

| 13 | Heating method | Recycled conduction oil heating with fuel heating |

| 14 | Discharge way | Automatically |

| 15 | Noise dB(A) | ≤85 |

| 16 | Running process | Semi-continuous |

| 17 | Delivery time | 20days |

| 18 | Weight | 20-50T (depends on the capacity) |

| Technical parameter of waste lube oil distillation plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | waste tyre, waste plastic, waste rubber, |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd