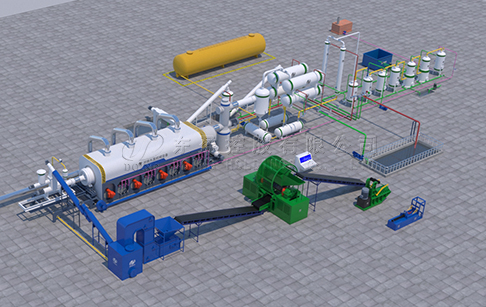

Waste tyre pyrolysis machine product introduction

Waste tyre pyrolysis machine is majoring in pyrolyzing used tyres to

kinds of valuable substances under normal pressure which can contain

8-10tons of waste tyre, whole or cut ones, large or small, and run about

23hours continuously within one day with about 2 people operate. The

valuable outputs are following: largest amount of tyre crude oil, carbon

black.

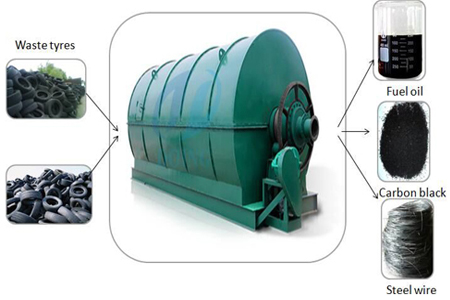

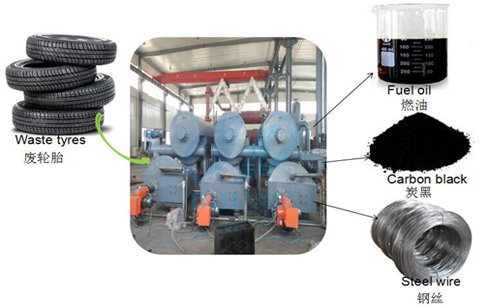

The below of picture is named waste tyre pyrolysis machine for disposal waste tyre, which is among the best sellers throughout year 2014.

Tyre pyrolysis machine

In

the meantime, a plenty of advantages are absolutely not ignored. Safe,

there are at least three main safety devices, which are connected with

the reactor and cooling system, to avoid syngas going back to the

reactor causing accidental explosion; besides, several safety valves are

working together with the alarms to keep the reactor running under

normal pressure in case the workers are absent of the site unexpectedly.

Environmental friendly, chemical water is employed in dedusting system

to cleanse the smoke to steam, and waste water from the cooling system

and syngas from burning processing both can be recycled to the reactor

and go back to the cooling system, such as heating the reactor and run

as circulating cooling water again; thus air and water pollution are

avoided. Energy-saving, used circular water from the cooling system and

syngas both can be reused to save a lot of fuel energy and clean water,

therefore reducing a large amount of cost for clients.

Besides,

the available markets for the above outputs are not hard to search,

actually very broad. First, the fuel oil from waste tyre can be sold to

manufacturers such as power plant, glass factory, cement factory,

ceramic factory, and boiler factory etc. Second, tyre carbon black can

be processed to make briquette and rubber in a unique formula with good

price. All the outputs have good selling lines, plus most tyre pyrolysis

machine run in industrial zone which include huge markets.

Fuel oil usage

| Technical parameter of waste tyre pyrolysis machine | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, waste plastic, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd