Converting tyre to fuel oil pyrolysis plant product introduction

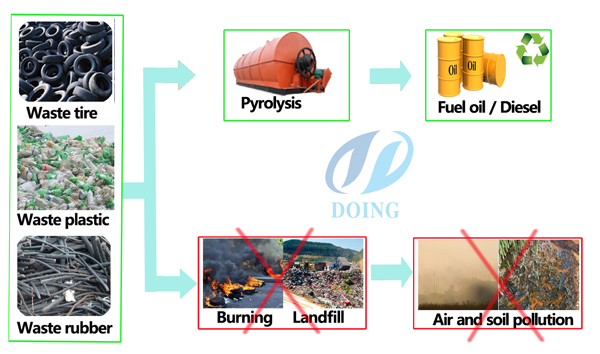

In our opinion the waste tire is a serious pollution to the environment. They dumped everywhere, they make the environment dirty, pollute water, when burned they will distribute bad smells with black smoke. When accumulated for a long time they are good place to breed virus carrying mosquitoes. What is the most important is that it is a waste of sources when we discarded the waste tires.

The tire to fuel oil pyrolysis plant is a plant to convert the waste tire to fuel oil. The plant converts the waste tire to fuel oil directly.

According to the capacity of tire to fuel oil pyrolysis plant, we put the shredded or whole tire into the reactor. The waste tire in the reactor will vaporize. Then the oil gas will go into condenser, the oil gas will become liquid oil. The liquid oil can be used as fuel oil directly or sold directly. The end product of tire to fuel oil pyrolysis plant is fuel oil, carbon black, and oil gas, some oil gas which cannot be recycled will lead to the reactor to heat the reactor.So there will be waste generated during the process.

Advantages of the tire to fuel oil pyrolysis plant that we manufacture

1. Higher oil yield rate we adopt auto-welding technology to weld the reactor which ensure the sealing of the reactor. So the waste tyre in the reactor will be pyrolysed fully. It will generate more oil gas. When the oil gas goes into the condenser, the cooling area is closed related to the oil yield rate. Inside our condenser there are total 57 condensing pipes with diameter 48 mm which means the cooling area of each condenser can be 13m2.Oil yield rate is guaranteed. When the temperature in the condenser reached about 180 degree Celsius. There will be oil gas generated Thus the oil yield rate can be further guaranteed.

2. Environmental friendly: The tire to fuel oil pyrolysis plant is zero pollution to the environment. The process is no pollution to the environment at all. The waste gas which cannot be condensed will be recycled back to the reactor to heat the reactor. No solid waste, No waste water.

3. Safety: Auto-welding technology ensures sealing of the reactor. Thus there will be no oil gas leaking to the air, thus will avoid accident. The anti-fire back system will prevent the oil gas going back to the reactor to cause accident. Vacuum system will prevent the oil gas from leaking. Professional heating treatment and X-ray detection guarantees sealing of the reactor. It is dangerous to burn the oil gas which cannot be condensed. We have safety device to deal with the oil gas which cannot be condensed Thus will guarantee the safety of burning. Professional thermometer, pressure gauge and safety valve.

4. Energy-saving: Well-sealing for heating system. No gas leaking and save energy. The exhaust gas will be recycled to heat the reactor.

| Technical parameter of converting tyre to fuel oil pyrolysis plant | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, waste plastic, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd