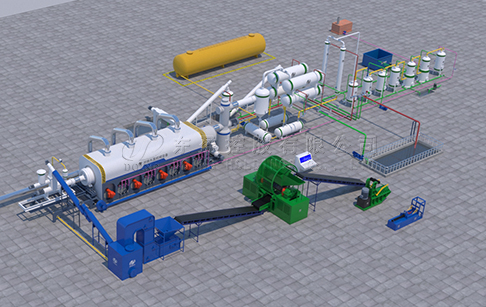

Waste tyre pyrolysis plant product introduction

Waste tyre pyrolysis equipment

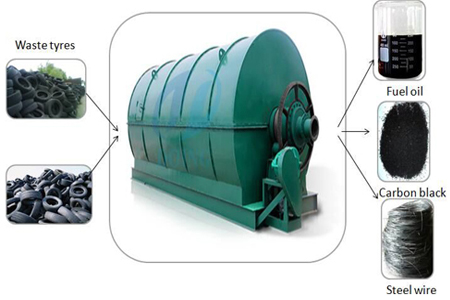

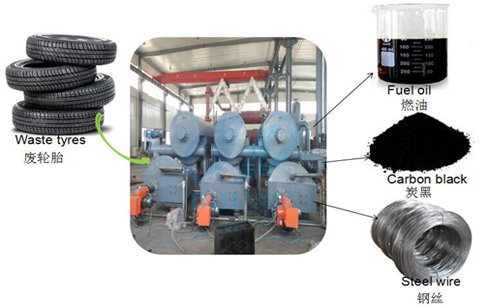

Waste tyre pyrolysis equipment is a machine converts the waste tire to oil as fuel. The equipment is used to convert the waste tyre to oil as a recycling industry. The waste tyre pyrolysis equipment mainly deals with the waste tyre. With the development of the economics we have a high stand for our environment. So the waste tyre pyrolysis equipment meets the command of the developing society. And the tyre pyrolysis equipment will protect our environment.

We henan doing mechanical equipment co.ltd manufacture high quality pyrolysis equipment, We have exported our waste tyre pyrolysis equipment to more than 50 countries in the world.Some may double whether the tyre pyrolysis equipment will pollute environment, the waste tyre pyrolysis equipment will not pollute the environment. For its serious quality control and air commission control there will be no exhaust gas polluting the environment. The fuel oil the waste tyre pyrolysis equipment generated can be used for cement factory, glass factory and so on.

We Henan doing mechanical equipment manufacture waste tyre pyrolysis equipment for the customers all over the world. The tyre pyrolysis equipment converts the waste tyre to oil for fuel,

We can not only relieve the pressure of the less and less energy but also will reduce the gas which makes the global warmer. The waste tyre pyrolysis equipment we manufacture is widely acknowledged to be the known pyrolysis equipment.

The raw material of the tyre pyrolysis equipment is waste tyre or waste plastic,The advantage of the waste tyre pyrolysis equipment is that both tyre and plastic can be processed in one reactor, the tyre pyrolysis equipment will bring the largest reward in this invest in the shortest time.the process of the waste tyre to oil is mainly a chemical react. The temperature and catalytic will influence the oil yield on large extent. We have special catalytic to catalyze the react and improve the oil yield rate.

So the tyre pyrolysis equipment is a fast developing industry, the energy will surely become more and more important in the future. The tyre pyrolysis equipment will become important as wll.

| Technical parameter of waste tyre pyrolysis plant | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, waste plastic, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd