Crude oil sludge treatment plant product introduction

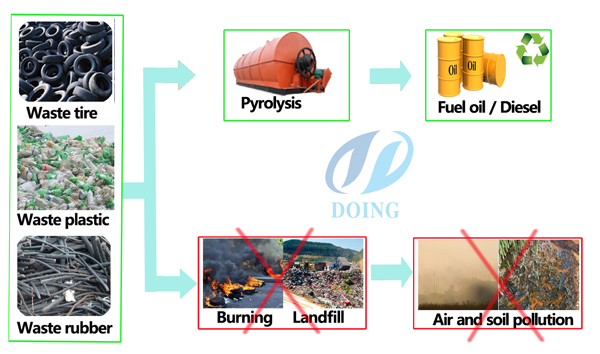

Oil sludge belongs to the by-product of drilling and refining oil, and they are also primarily a mixture of oil and water. But the most important thing is that unprocessed oil sludge will cause great harm to environment. That's why oil sludge treatment pyrolysis plant is a feasible solution.

DOING crude oil sludge treatment plant project site

Our crude oil sludge treatment plant adopts the most advanced sludge pyrolysis technology and is popular in many countries. DOING crude oil sludge treatment plant include these main parts, such as screw feeder , reactor, buffer chamber, condensers, oil-water separator, water seal device, oil tank, deducting system, vacuum system, tail gas cleaning system, exhaust gas burner, thermometer, etc. Equipped with special machine to process all wastewater and exhaust, our crude oil sludge treatment plant generates no pollution to environment. In addition, the crude oil sludge treatment plant comes with pressure gauge, automatic warning device, which make certain that it is safe for use.

Next I will tell you how the crude oil sludge treatment plant works:

1. Feeding

If your oil sludge is liquid, it needs to be packed in ton bags firstly, while solid oil sludge can be fed directly. Then feeding the oil sludge into reactor by the sealed screw conveyor.

2. Heating

fire the fuel in the burning room by diesel, natural gas, LPG and so on. The hot air will flow into the reactor for heating. When the inner temperature of the reactor reaches to a certain degree, the oil gas will be generated, then goes into the buffer chamber firstly where the heavy particles will be liquefied into heavy oil and drop in the heavy oil tank and the light oil gas rise up.

3. Cooling

The light oil gas goes into the condensers uniformly. Through 3-steps condensers, a large scale of oil gas will be liquefied into fuel oil and enter oil tank. The uncondensable gas will be desulfurated and cleaned in the water seal, then recycled to the burning room to provide heat, saving a lot of fuel.

4. Slag discharge

After all the above is finished, the slag will be discharged by the auto screw discharger. The main component of this slag is soil.

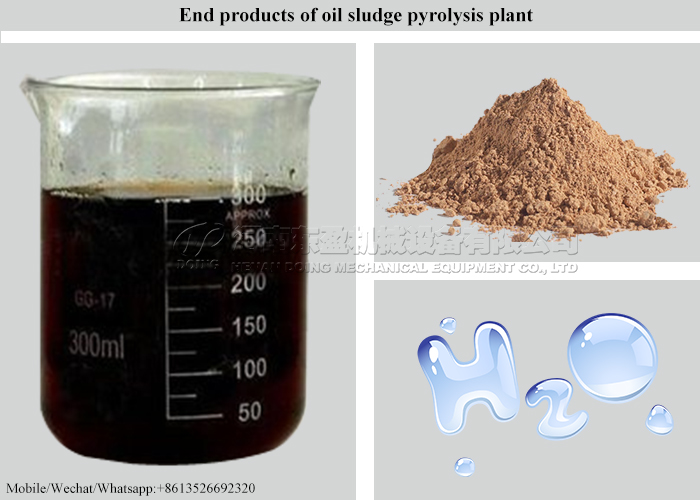

Through the oil sludge pyrolysis process, we can ger fuel oil, soil and water. But the ratio of these three products is uncertain, determined by your raw materials. In general, the oil content of oil sludge is 10-30%. The oil made from oil sludge is of high quality, so you can use it as fuel directly in steel factory, boiler heating, heavy oil generator, cement factory, etc. The soil produced is not much different from ordinary soil, and can be used directly for making bricks or paving.

The end products made from crude oil sludge

It is highly beneficial to start a crude oil sludge treatment plant, because not only high value oil can be got, but also you can get subsidies from oil sludge producers for this treatment. Meanwhile, If the crude oil sludge treatment plant cost is low, the profit will be even greater. The cost of our crude oil sludge treatment plant is always the most reasonable. In order to meet different requirements of customers, we have designed different models of crude oil sludge treatment plant for sale. If you have interest in this plant, please send us an inquiry! We will reply in 24 hours!

| Technical parameter of crude oil sludge treatment plant | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Crude oil sludge, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd