Waste tyre recycling to fuel oil pyrolysis plant product introduction

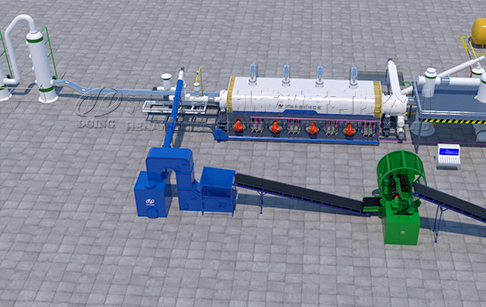

Waste tyre recycling to fuel oil pyrolysis plant

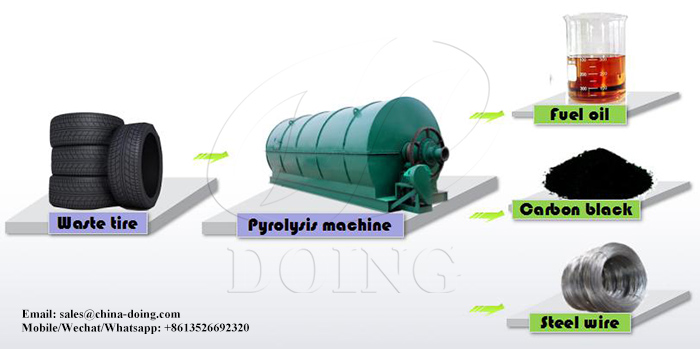

Waste tyre recycling to fuel oil pyrolysis plant is a set of waste recycling equipment which can convert waste tyre into useful fuel oil through pyrolysis reaction. After the pyrolysis working of waste recycling to fuel oil pyrolysis plant, you can get fuel oil, carbon black, steel wire and incondensable gas. Now, let me show you how the waste tyre recycling to fuel oil pyrolysis plant work.

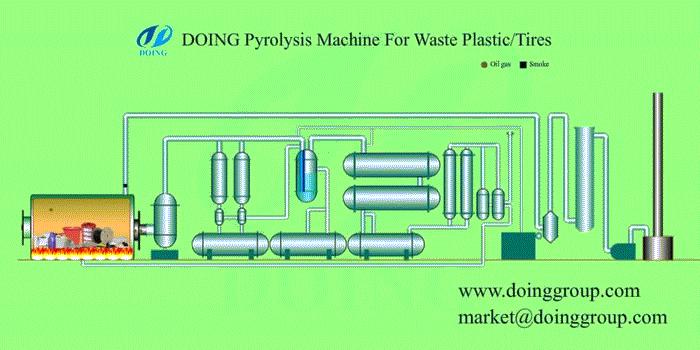

The working process of DoingGroup's Waste tyre recycling to fuel oil pyrolysis plant as follows:

1. Feeding the waste tyres into the reactor and make sure both the feeding door and slagging door are closed tightly.

2. Heating the pyrolysis reactor. With the rising of temperature, the waste tyre will be pyrolyzed into oil gas.

3. Condensing the oil gas through the cooling system. The pyrolysis oil gas enters the condensing system and is liquefied into heavy oil and falls into the oil tank.

4. Cleaning the tail smoke. The dedusting and deodorization of the heavy oil in the oil tank will be disposed by the smoke cleaning system.

5. Discharging the carbon black. When the temperature in the reactor is cooled to below 40°C, the carbon black in the furnace will be discharged through the underground sealing device to avoid secondary pollution to the environment.

6. Pulling out the steel wire. After discharging the carbon black, opening the feeding door, and pulling out the steel wire as son as possible better control it within 5~10 minutes.

Waste tyre recycling to fuel oil pyrolysis plant working process

Main features of waste tyre recycling to fuel oil pyrolysis plant:

1.Safety

Doing waste tyre recycling to fuel oil pyrolysis plant possesses strict quality control system and professional safety devices guarantee the plant running safely and wins a good reputation from customers.

2.Energy saving

Combustible gas that cannot be liquefied will be recycled and used as fuel to heat the reactor. The reuse of this gas can save fuel costs in the production process of waste tyre recycling to fuel oil pyrolysis plant.

3.Environmental friendly

Professional dedusting systems ensure our pyrolysis oil to diesel plant runs zero pollution.

Now, more and more people have realized the lucrative and efficient of waste recycling to fuel oil pyrolysis plant. If you are also interested in this plant, welcome to contact us!

| Technical parameter of waste tyre recycling to fuel oil pyrolysis plant | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, waste plastic, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd