Industry news / DATE:2024/5/9

Recently, DOING has been inundated with inquiries from both domestic and international clients seeking a solution to dispose of waste engine oil. That sounds hard to achieve. How is it possible to turn waste engine oil that has no use value into energy? Surprisingly, DOING's waste oil distillation machines offer precisely this capability, effectively disposing of waste engine oil into diesel fuel. And this article delves into what a waste oil distillation machine is and how it to dispose of waste engine oil to diesel fuel.

DOING waste oil distillation machine for sale

Waste oil distillation machine is a device that extracts specific substances from raw materials and is dedicated to refining diesel oil from waste engine oil, used lube oil, crude oil and pyrolysis oil. DOING's waste oil distillation machines are at the forefront of this technology, offering a comprehensive solution for disposing of waste engine oil.

The following describes the specific process flow of the DOING waste oil distillation machine, which is divided into the following steps: distillation - cooling - dewaxing and degluing - further decolorization.

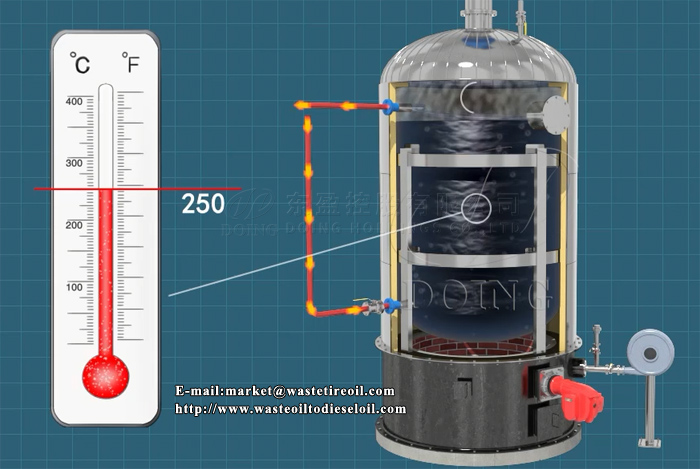

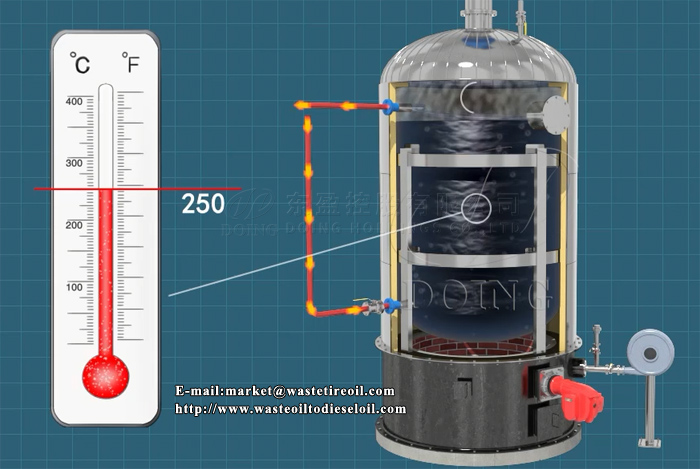

Step 1: Distillation

Firstly, the waste engine oil is pumped into the distillation reactor, and the heating system is turned on to heat the reactor. When the temperature continues to rise, the oil and gas will continue to be distilled out, which can filter out some heavy oil impurities.

Heating and distillating of DOING distillation reactor

Step 2: Cooling

The resulting oil gas will be cooled by a condensing system in which circulating water cools the oil into liquid oil, which is then collected in temporary storage tanks.

Step 3: Dewaxing and degluing

Since the liquid oil in the temporary storage tank is only distilled without changing the properties of the oil, it cannot be stored for a long time. Catalysts are needed to remove the wax and glue from the liquid oil to get the non-standard diesel with good quality, and it can be stored for a long time.

Further purification system of DOING waste oil distillation machine

Step 4: Further decolorization (optional)

If the customer wants to get a better color and texture of diesel, then the customer can choose to use a further decolorization system to decolorize the diesel, and finally get a light yellow and transparent diesel, such diesel market price will be higher. And the final obtained diesel can be used in heavy machinery, diesel generator, boiler, etc.

Applications of obtained diesel oil

Now I believe you should know what is the best machine to dispose of waste engine oil and how to turn the waste oil into diesel oil with the waste oil distillation machine. If you have waste oil or other used oil resources and want to know how much it costs to invest in the waste oil distillation machine project, please contact the DOING professional business manager in time to get a more accurate quote.

Inquiry more what is the best machine to dispose of waste engine oil? information

Leave a message in the below form to get more information about pyrolysis plant project, our engineer will contact you ASAP to analysis pyrolysis plant project cost for you.

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd