Industry news / DATE:2025/7/25

In recent years, with the continuous advancement of waste recycling technology, pyrolysis oil, derived from the processing of waste materials like tires and plastics, has gradually entered the public eye. So, is pyrolysis oil flammable? And who uses it?

Plastic pyrolysis oil and Tire pyrolysis oil

The Characteristics of Pyrolysis Oil

Pyrolysis oil is a fuel oil produced using pyrolysis equipment to process waste materials such as waste tires, plastics, sludge, and rubber. It has a dark brown color, high calorific value, moderate viscosity, and low ash and carbon residue content. Its density ranges from 950-970 kg/m³, and its flash point is relatively low. The H/C ratio of pyrolysis oil is 1.3%-1.5%, and its calorific value falls between 40-43 MJ/kg. These properties make pyrolysis oil comparable to conventional petrochemical fuels, giving it significant energy value and broad application prospects.

Pyrolysis oil Gross Calorific Values

The Flammability of Pyrolysis Oil

Yes, pyrolysis oil is flammable. Its flammability primarily stems from its high calorific value and the combustible organic compounds it contains. When ignited, it burns rapidly and releases a large amount of heat, making it suitable for use as fuel. However, due to its relatively low flash point, pyrolysis oil is also somewhat volatile. Proper storage and handling are required to prevent safety incidents.

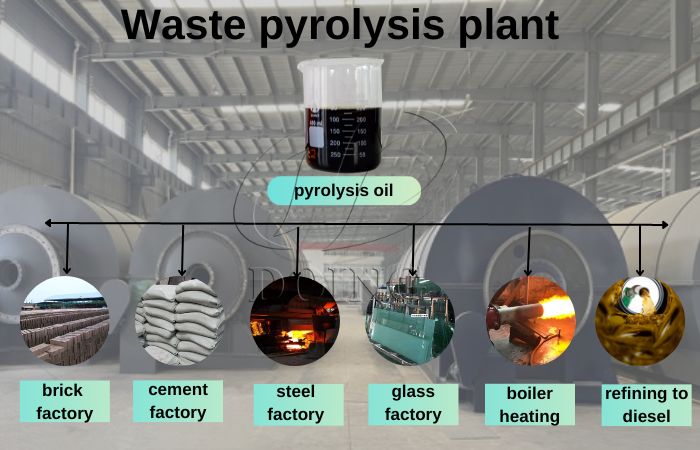

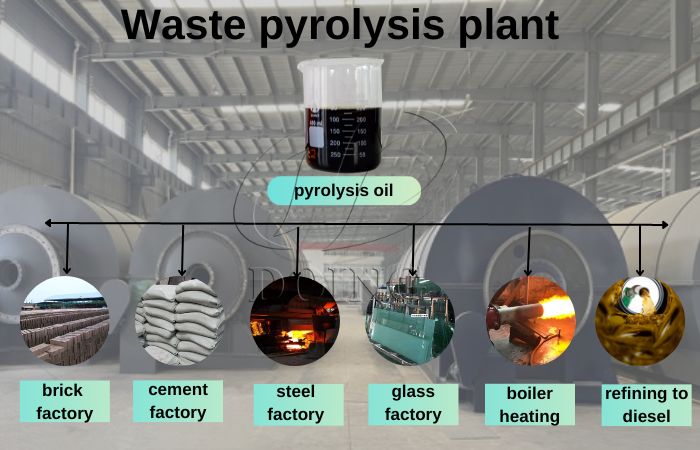

The Users of Pyrolysis Oil

Industrial Energy Sector

Cement Plants: During cement production, large amounts of heat are required. Pyrolysis oil can be used as a substitute for traditional fossil fuels like coal and natural gas, providing the necessary thermal energy for the calcination process of cement clinker.

Glass Factories: The glass melting process demands high temperatures. Pyrolysis oil, with its high calorific value and stable combustion performance, meets the temperature requirements of glass melting furnaces.

Power Plants: Some small-to-medium-sized power plants use pyrolysis oil to generate electricity. After proper treatment, pyrolysis oil can be burned in power plant boilers to produce steam, driving turbines and generating electricity. This provides a new way for distributed energy generation and enhances energy utilization efficiency.

Steel Mills: Pyrolysis oil can be used in steel heating furnaces and hot rolling processes. Its high calorific value quickly heats steel billets to the required temperature, improving production efficiency. Additionally, the combustion products of pyrolysis oil have minimal impact on steel quality, making it a viable fuel option for steel mills.

Boiler Factories: Boiler factories represent one of the key application areas for pyrolysis oil. Various industrial boilers can be modified to burn pyrolysis oil, supplying heat and power to enterprises. Boiler factories can also develop dedicated pyrolysis oil burners and combustion systems to improve combustion efficiency and reduce emissions.

Distillation: If you want to obtain a product of higher quality, you can use the DOING distillation plant to further distill it to obtain high-quality diesel, which can be used in diesel engines of generators, agricultural machinery, mining machinery, ships, etc.

Applications of pyrolysis oil

Chemical Industry Sector

Pyrolysis oil contains benzene, toluene, xylene, and other important chemical raw materials. Through processes such as fractional distillation and refining, these components can be extracted and further processed into a range of chemical products, such as solvents, resins, and plastics, providing raw materials for the chemical industry and reducing reliance on traditional petrochemical resources. Besides that, tire pyrolysis oil is rich in limonene, a valuable organic solvent with low toxicity. Some industries will extract limonene from pyrolysis oil for further chemical uses.

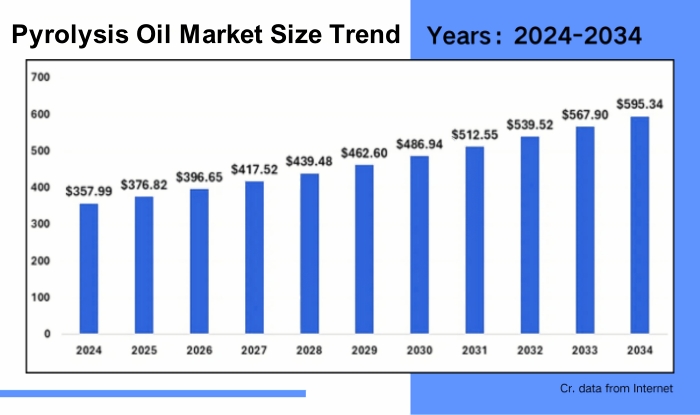

The Significance and Prospects of Pyrolysis Oil

Pyrolysis oil not only provides a solution for waste disposal but also creates economic value through resource recycling. Its applications in the energy and chemical industries help reduce reliance on traditional fossil fuels, alleviate energy shortages, and decrease environmental pollution. As pyrolysis technology continues to advance and improve, the quality and yield of pyrolysis oil will further increase, expanding its application scope. In the future, pyrolysis oil is expected to play a more critical role in the economy and development.

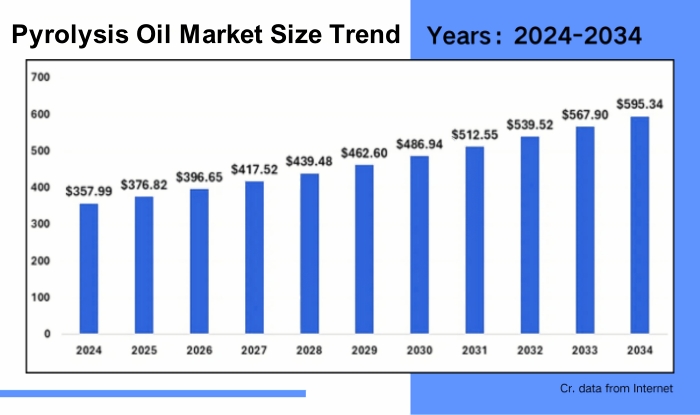

Pyrolysis oil market size trend

For enterprises and individuals interested in pyrolysis oil, staying informed about the latest advancements in pyrolysis technology and market trends is essential. If you want to explore whether your materials are suitable for pyrolysis projects and confirm py whetherrolysis oil meets your needs, feel free to contact DOING Company. Our professional business managers will provide detailed consultations and tailored solutions.

Inquiry more is pyrolysis oil flammable? who uses pyrolysis oil? information

Leave a message in the below form to get more information about pyrolysis plant project, our engineer will contact you ASAP to analysis pyrolysis plant project cost for you.

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd