Company news / DATE:2025/12/31

In December 2025, DOING company secured a deal with a Philippine client for DY-3 tire oil distillation equipment. The client presently runs two tire pyrolysis units, transforming scrap tires into tire oil. This partnership seeks to boost the value of their output by further distilling the generated tire oil into diesel for local sales.

DOING tire oil distillation equipment details

Having acquired an initial grasp of waste pyrolysis oil distillation methods, the Philippine client reached out to DOING Company. Their primary need was for a dependable, effective, and eco-conscious tire oil distillation equipment. Following a review of DOING's tire pyrolysis oil distillation and purification solutions, and to proceed prudently, the client opted for initial production experiments using compact tire oil distillation equipment prior to committing to major investments. This approach would confirm the market demand, suitability, and financial practicality of distilling tire oil into diesel. As a result, DOING suggested this DY-3 tire oil distillation equipment.

Regarding the DY-3 Tire Oil Distillation Equipment

Distillation Procedure: DOING’s waste oil distillation equipment combines distillation, catalytic treatment, decoloring, and odor removal. This integrated method efficiently eliminates resins, contaminants, pigments, and smells from tire oil, yielding a transparent, low-smell non-standard diesel with reliable burning properties ideal for farm equipment, power generators, and industrial furnaces, among others.

Capacity Suited for Trials: With a DY-3 processing rate, it facilitates handling several small batches and refining operational settings progressively. This consistent output aids in real-world assessments of product standards, uniformity, and functionality in regional environments.

Process of tire oil distillation equipment

Budget-Friendly Strategy: Compact trial-sized machinery demands minimal area. A DY-3 pyrolysis oil distillation setup covers about 50 square meters, lowering upfront financial exposure and running expenses, enabling clients to investigate tire pyrolysis oil to diesel distillation prospects with managed spending.

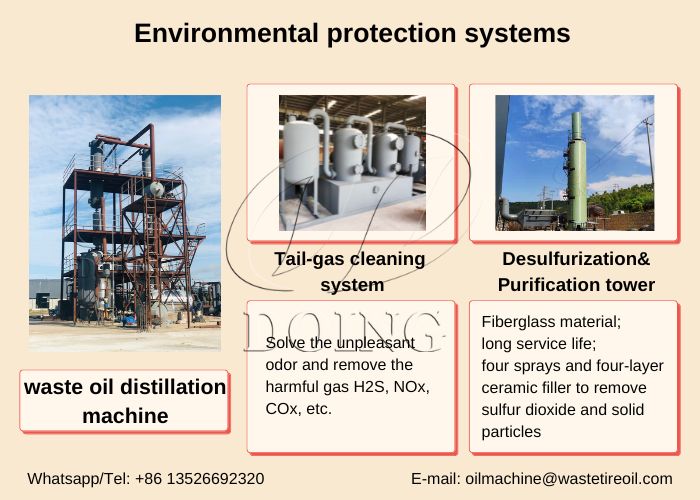

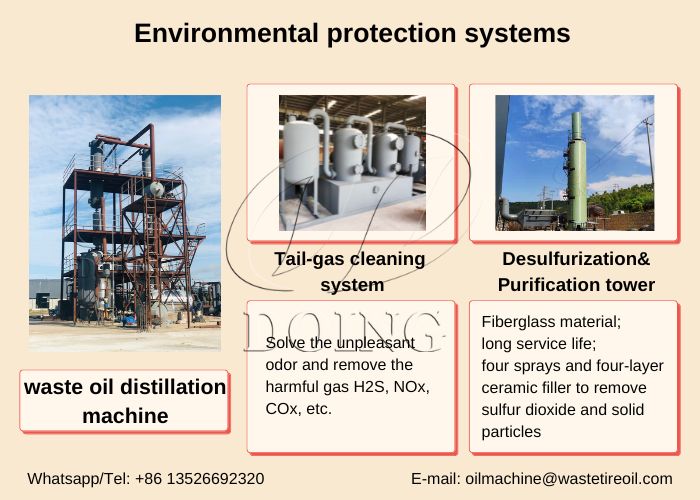

Superior Eco-Friendliness: DOING's waste oil distillation equipment features a full-spectrum pollution control setup to cut down on discharges and ecological effects. Key elements include a sophisticated exhaust purification unit that processes flue gases via multi-level filtering and washing, greatly decreasing dust particles and toxic substances. The sealed-circuit design enhances waste oil distillation productivity while curbing spills. Additionally, the syngas capture and reuse mechanism enables non-condensable burnable gases to serve as reactor fuel post-water separation and sulfur removal, cutting reliance on outside energy and emission outputs.

DOING tire oil distillation equipment environment protection systems

DOING anticipates that this DY-3 tire oil distillation equipment will enable the client to effectively confirm the market promise and profitability of converting tire oil to diesel.

DOING tire oil distillation equipment manufacturer

If you're interested in running modest-scale experiments to probe emerging markets or launching extensive waste oil/pyrolysis oil to diesel distillation ventures, DOING Company is ready to assist. Offering a broad selection of machinery focused on productivity, ecological care, and reliability, we can guide your initiative from early trials to complete operations.

Inquiry more philippine client selects doingchr(39)s dy-3 tire oil distillation equipment for market evaluation information

Leave a message in the below form to get more information about pyrolysis plant project, our engineer will contact you ASAP to analysis pyrolysis plant project cost for you.

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd