A pyrolysis system can convert organic materials (like used tires, waste plastics, oil sludge)into useful products such as fuel oil, combustible gas and other valuable materials. The pyrolysis system consists of feeding system, reactor vessel, heating system, cooling system and collection system. The following takes DOING used tire batch pyrolysis system as an example to explain in detail the process of pyrolysis system and how the pyrolysis system works.

There are two kinds of feeding methods of pyrolysis system: feed used tires into pyrolysis reator pyrolysis system by labor or by automatic feeding machine.

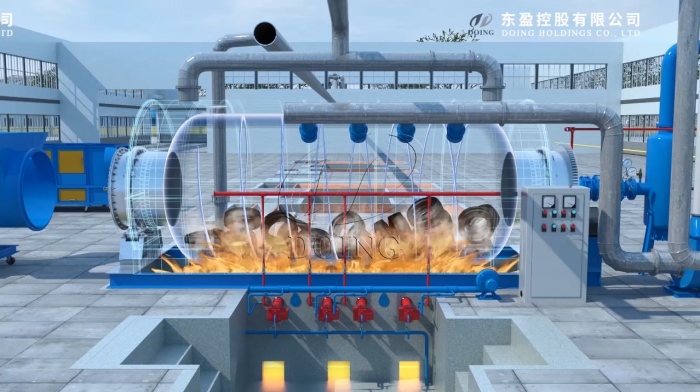

The reactor in the pyrolysis system is heated by a burner. In this process of pyrolysis system, temperature in the reactor gradually increases. When the temperature gets about 160℃, the used tires begin to be pyrolyzed and produce oil and gas.

After the temperature reaches 200℃, control the heat to make the temperature rise steadily. It is best to rise 1℃ every 1-2 minutes. And then keep the temperature between 200-300℃, the heating process of the pyrolysis system lasts for 8-10 hours. After that, the pyrolysis system process in the reactor is basically completed. At last increase the firepower to make the temperature exceed 300℃, and the rest of the incompletely pyrolyzed raw materials can be all heated and pyrolyzed.

The pyrolysis system process of reator heating

The pyrolysis system process of reator heating

Our newest cooling system of used tires pyrolysis system, which has four condensing units, total seven condensers to fully extract all fuel oil from your raw material.

Each vertical condenser has four 108 condensing tubes surrounded by condensate water, which greatly increases the contact area between oil gas and condensate water.

The oil-water separator is a safety device to prevent oil gas flow back, also it's cooling the oil gas into liquid oil.

The condenser of DOING pyrolysis system

The condenser of DOING pyrolysis system

There are 37 seamless tubes per condenser, total 74 tubes, almost 90% of oil gas will cool down here.

If the fire of heating process of pyrolysis system is too fierce, the oil gas flows too fast, there is a small part of the oil gas will not be condensed. This set of condensing towers make the oil gas flow from the bottom to the top, which can condense the remaining oil gas into oil to the greatest extent.

The oil will be collected in the oil tank after cooling and separating, the combustible gas will be transported to the reactor and used as raw material to heat it, and the non-combustible gas will be discharged after treatment. When the reactor cools down, the carbon black is discharged from the slag discharge port on the side of the reactor.

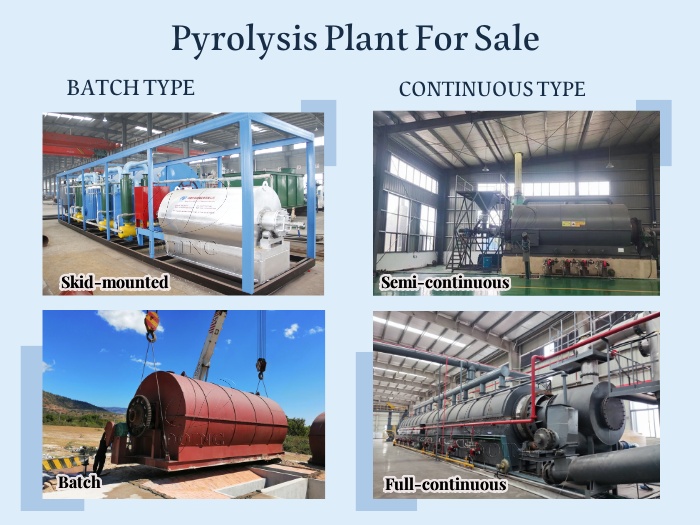

The above is the introduction to the working process of DOING batch used tires pyrolysis system. It is a sustainable and environmentally friendly process that can help waste recycling. In addition to batch used tires pyrolysis system, Doing also has semi-continuous pyrolysis systems and full continuous pyrolysis systems. These working process pyrolysis systems is almost the same, but they have their own characteristics and meet the different needs of different customers.

Different types of DOING pyrolysis systems

Different types of DOING pyrolysis systems

If you are planning to build a pyrolysis system factory, you can contact us at any time. DOING will provide you with the right pyrolysis system according to your specific needs.