Waste tires are high-molecular organic compounds, mainly made of natural rubber, synthetic rubber, fiber cord, carbon black and other organic additives. We can use waste tire pyrolysis machine to process waste tires into fuel oil, carbon black, steel wire, combustible gas and other products under high temperature and oxygen-free conditions.

Waste tire pyrolysis plant

And here is the detailed production process from waste tire to fuel oil:

1.Feeding:

Feed raw materials are transported to the reactor of waste tire pyrolysis machine. There are two feeding methods: manual feeding and automatic feeder. The automatic feeder can shorten the feeding time by half, from 3-4 hours to 1-2 hours, effectively speeding up the feeding speed.

2.Heating:

Heat the reactor with fuels to pyrolyze the waste tires under high temperature. Generally when the temperature reaches to around 160celsius, there will be oil and gas generation. And the fuels can be used for coal, natural gas, fuel oil, non-condensing gas produced in waste tire pyrolysis process.

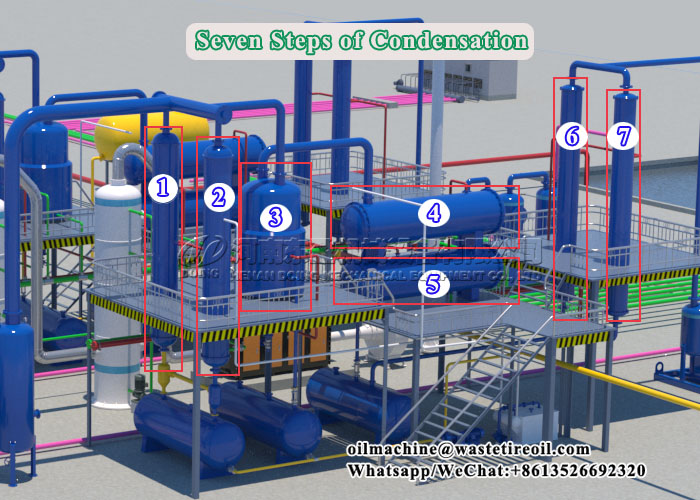

3.Cooling:

Oil and gas are cooled by the cooling system (four-step condensation) and condensed into oil, which can be observed through the sight mirror. The whole cooling system adopts circulated water cooling, which is environmentally friendly and pollution-free and can be reused.

Cooling system

4.Exhaust gas recovery and utilization:

In the process of waste tire pyrolysis, in addition to oil and gas, there will also be part of the combustible but non-condensable gas, which is called non-condensable gas, or tail gas. After water sealing, this gas can be directly recycled for heating pyrolysis furnace, at the same time saving the investment cost of fuel.

5.Flue gas treatment:

For different national standards, DOING provides different flue gas treatment measures. Some countries with low requirements, water film dust removal can reach the standard. However, like European and American countries, DOING will provide customers with water film dust removal and glass fiber reinforced plastic desulfurization tower, which can effectively remove the sulfur content in the flue gas and achieve higher environmental protection standards.

6.Carbon black and steel wire slag discharge:

After the pyrolysis process, the reactor is cooled to a certain temperature, and the residual substances in the reactor are discharged, mainly carbon black and steel wire.

The above is a detailed introduction of waste tire to fuel oil production processes designed by DOING company. As a professional manufacturer, Doing company have helped customers install the pyrolysis machine in more than 90 countries and regions. If you also have interest, welcome to contact us. We can customize you both batch type and full-automatic type waste tire pyrolysis machine according to your requirements at a favorable price.