In today’s world faced with increasingly severe plastic waste pollution, how to effectively recycle and utilize waste plastics has become a critical issue. Pyrolysis technology, as an emerging waste plastic recycling method, has garnered significant attention. I will take DOING pyrolysis technology as an example to show you how pyrolysis technology can improve the recycling value of waste plastics.

DOING waste plastic pyrolysis equipment

Pyrolysis refers to the process of decomposing waste plastics into smaller molecules under high temperatures (typically between 300°C and 600°C) in an oxygen-free environment. During this process, waste plastics undergo thermal cracking, transforming into high-value products such as fuel oil, carbon black, and non-condensable gases similar to natural gas. Unlike traditional waste plastic recycling methods like landfilling and incineration, pyrolysis not only effectively addresses waste plastic issues but also generates economically valuable products, offering dual benefits for environmental protection and the economy.

DOING waste plastic pyrolysis technology

High Efficiency Conversion

DOING’s pyrolysis technology excels in its high-efficiency conversion of waste plastics. The equipment operates under anaerobic conditions at high temperatures to decompose waste plastics into fuel oil and other chemicals. It effectively handles various types of waste, including plastics, municipal solid waste, tire rubber, and biomass materials.

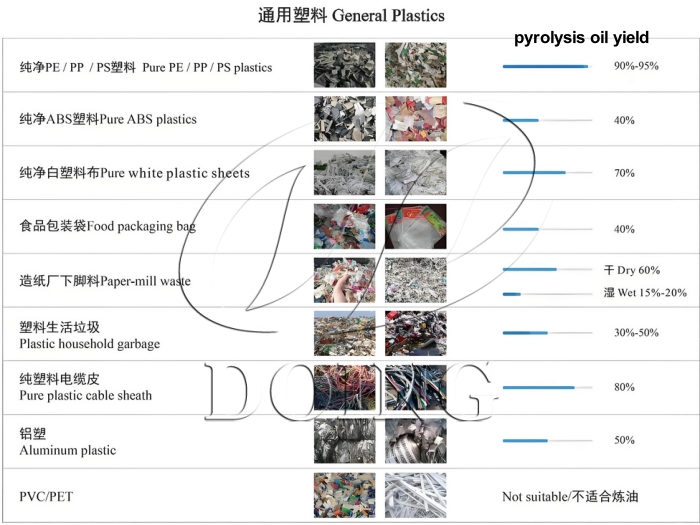

For high-quality plastics such as PP, PE, and PS, DOING pyrolysis equipment achieves exceptionally high conversion rates, with oil yields exceeding 80%. Even when processing mixed plastic materials, the oil yield remains at least 50%, along with approximately 20% to 30% carbon black powder. This high conversion rate significantly enhances the recycling efficiency of waste plastics, enabling the production of more valuable products from the same amount of waste.

Waste plastic pyrolysis oil yield

Valuable Products

By adjusting the pyrolysis temperature gradient of DOING’s pyrolysis equipment, plastic waste can be efficiently converted into high α-olefin content oil (HFO), which holds high economic value. Plastic pyrolysis oil serves as a high-quality industrial heating fuel, widely used in boilers, glass factories, steel mills, cement plants, and other industries. Carbon black, another byproduct, is a key material in the rubber industry, particularly in tire manufacturing. It also finds applications in the plastics, ink, coatings, and other sectors as a reinforcing agent, coloring agent, or conductive material. With the development of the new energy industry, its use in lithium batteries and other fields is becoming increasingly prominent.

Moreover, pyrolysis oil can be further refined into high-quality diesel using DOING waste oil distillation equipment. This diesel can be utilized in power generation, mining machinery, agricultural equipment, and more, further expanding the application scope and economic value of pyrolysis products.

Final products and applications from waste plastic pyrolysis equipment

Environmentally Friendly

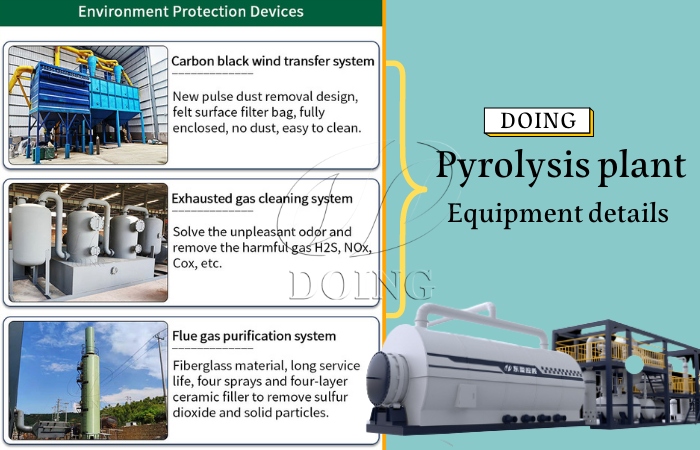

Compared to traditional landfilling and incineration methods, pyrolysis technology significantly reduces environmental pollution. Unlike outdated pyrolysis equipment, DOING’s pyrolysis technology has undergone continuous innovation and improvement, balancing safety and environmental protection. Based on the standard configuration, additional optional features like dust removal system, exhaust gas purification system can be added to enhance environmental performance, ensuring compliance with EU standards.

DOING waste plastic pyrolysis equipment environment protection devices

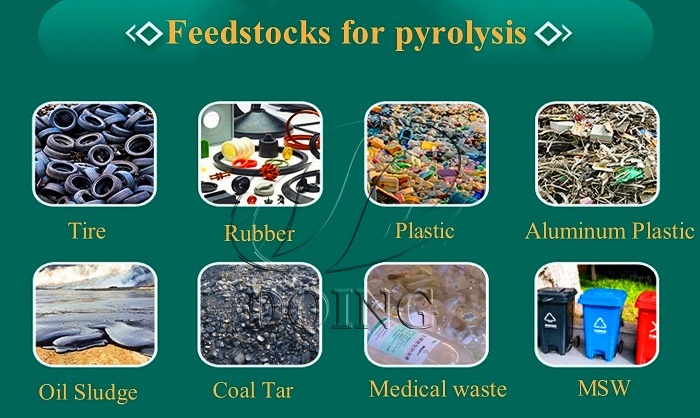

DOING Company, specializing in waste pyrolysis devices for over 14 years, is one of the few domestic and international suppliers offering comprehensive waste recycling solutions. From batch pyrolysis equipment to semi-continuous and fully continuous ones, DOING can handle various types of waste, including waste tires, rubber,plastic, oil sludge, household waste, medical waste and hazardous waste.

Raw materials for pyrolysis

DOING’s pyrolysis equipments feature advanced technology and reliable performance. The equipment adopts a unique heating furnace design, enabling even heat distribution and improving pyrolysis efficiency. The automatic feeding and discharging system enhances operational convenience and safety. Additionally, the equipment is equipped with comprehensive safety devices, such as temperature and pressure monitoring systems and emergency relief valves, ensuring stable and safe production. At present, our plastic pyrolysis technology has been widely used in many countries, such as China, Mexico, Canada, India, Thailand, India, South Africa, Indonesia, Vietnam, Thailand, Fiji, Haiti, Brazil and other countries, and has been widely praised.

DOING waste plastic pyrolysis equipment manufacturer

Pyrolysis technology plays a crucial role in improving the recycling value of waste plastics. DOING’s pyrolysis equipments, with their high-efficiency conversion, valuable product output, and environmental benefits, provide an ideal solution for waste plastic recycling. If you have questions about pyrolysis technology or are interested in DOING’s pyrolysis equipments, please feel free to contact us at any time. We are committed to offering the most professional waste recycling solutions to help you create greater economic and environmental value from waste plastics.