Industry news / DATE:2023/11/23

As a top and reliable manufacturer of pyrolysis system, DOING has been committed to researching and enhancing the pyrolysis systems, and now we have three types of pyrolysis systems for our customers to choose:

1. Batch type pyrolysis system

The batch pyrolysis system is one of the simplest and most common types of pyrolysis systems, which has the processing capacity between 100/500KG and 20TPD. The smallest capacity 100/500KG per batch can be designed to the frame type, providing more convenience for our customers.

DOING batch type pyrolysis system for sale

DOING batch type pyrolysis system for sale

For batch type pyrolysis system, the working process is feeding, heating, oil gas production and cooling, pyrolysis reactor cooling down, and final products discharging, each process has to start after the former process is finished. But for some customers, this type is a cost-effective choice.

2. Semi-continuous pyrolysis system

The semi-continuous pyrolysis system operates in a similar manner to the batch type pyrolysis system but incorporates some automation for improved efficiency. Because the semi-continuous pyrolysis system can discharge the carbon black without cooling the pyrolysis reactor, the pyrolysis system can reach the working yield of three batches in two days, which has the processing capacity of 12/15/20+TPD and is suitable for middle-scale operations.

DOING semi-continuous pyrolysis system for sale

DOING semi-continuous pyrolysis system for sale

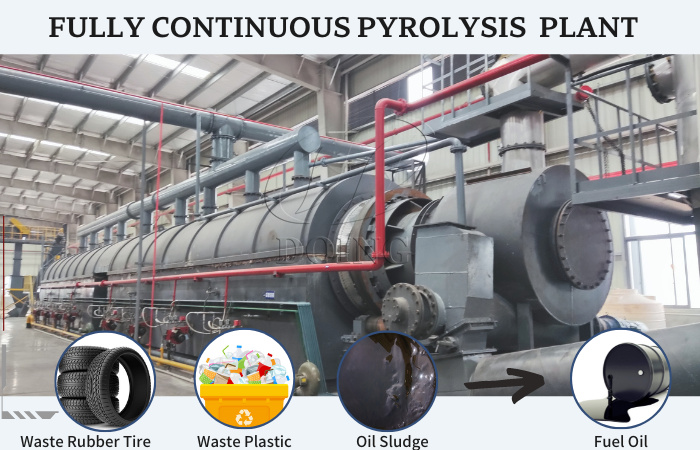

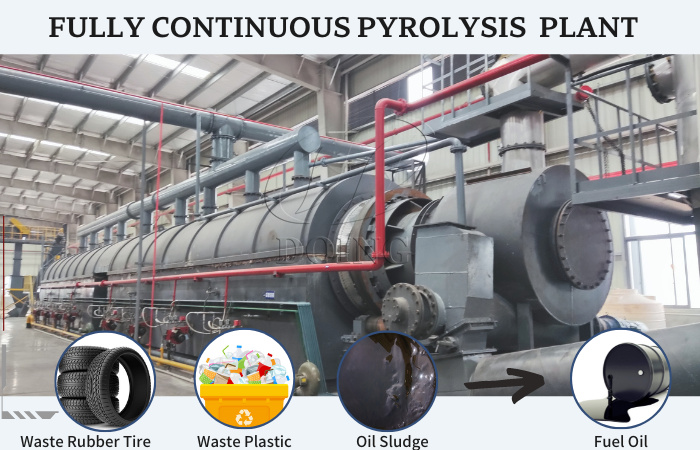

3. Fully continuous pyrolysis system

The fully continuous pyrolysis system is the most advanced and efficient type of pyrolysis system, which has the processing capacity of 20/30/40/50+TPD. It operates continuously, meaning there is a constant feed of waste material and a continuous discharge of pyrolysis products. Equipped with an automatic feeding system, multiple reactors, and an advanced PLC control system, this type is known for its optimal performance. Additionally, because the continuous pyrolysis system adopts the sealed operation system, it is relatively more environmentally friendly. It is suitable for large-scale operations and offers high productivity and energy efficiency.

DOING fully continuous pyrolysis system for sale

DOING fully continuous pyrolysis system for sale

Each type of pyrolysis system has its advantages and is suited to different applications and scales of operation. The choice of pyrolysis system depends on factors such as the type and volume of waste material, desired product outputs, processing capacity, and budgetary considerations. By selecting the appropriate pyrolysis system, businesses and entrepreneurs can effectively convert waste into valuable resources while generating environmental and economic benefits.

If you are considering ordering a pyrolysis system but are unsure which type best suits your needs, please feel free to contact us with details about your processing raw material, capacity, etc. We can provide a detailed scheme to meet your specific requirements.

Inquiry more what are the different types of pyrolysis systems? information

Leave a message in the below form to get more information about pyrolysis plant project, our engineer will contact you ASAP to analysis pyrolysis plant project cost for you.

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd DOING batch type pyrolysis system for sale

DOING batch type pyrolysis system for sale DOING semi-continuous pyrolysis system for sale

DOING semi-continuous pyrolysis system for sale DOING fully continuous pyrolysis system for sale

DOING fully continuous pyrolysis system for sale