Industry news / DATE:2025/11/21

Thermochemical conversion (TCC) is a process that uses heat energy to break down organic materials such as plastic waste into simpler molecules. Common thermochemical conversion processes include combustion, gasification, pyrolysis, and hydrothermal conversion. However, among the many thermochemical conversion processes (TCC), pyrolysis is the most effective process for making fuel from waste plastics, due to its high practicality and wide application potential.

Thermochemical conversion processes-pyrolysis

Pyrolysis, the core of thermochemical conversion (TCC) process of making fuel from plastic waste, providing stable product yields and its principle is simple: heating plastic waste in an oxygen-free environment (380–550℃) to break long-chain hydrocarbons into small-molecule compounds. These compounds condense into liquid fuel (plastic pyrolysis oil), while non-condensable gases and solid carbon black are produced as byproducts.

For businesses focused on converting plastic waste into profitable, usable products, pyrolysis outperforms other TCC processes in three key aspects:

1.Cost-effectiveness: Reduced operating costs

Lower energy consumption: Typically, high-calorific-value, non-condensable combustible gases are recycled to power the reactor, thus reducing external energy requirements.

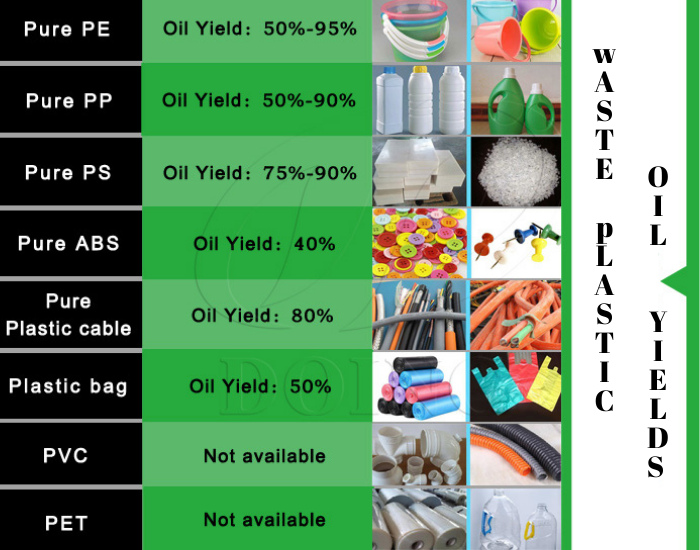

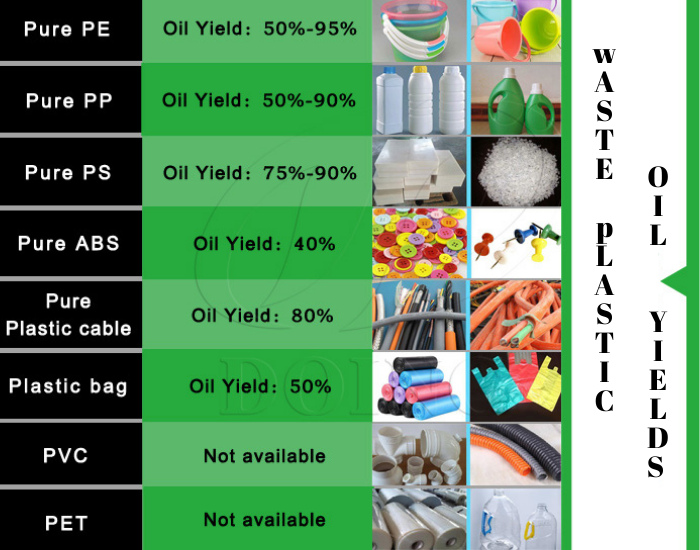

Flexible Raw Material Handling Capacity: TCC can process various types of plastics, such as PP, PE, PS, ABS, and aluminum-plastic composites, including mixed plastics, contaminated plastics, and difficult-to-recycle plastics, without the need for expensive sorting and pretreatment.

DOING making fuel from plastic waste types oil yield

2.High economic efficiency: The resulting fuel oil and carbon black have a wide range of applications and can be sold for profit.

Plastic pyrolysis oil (PPO): Plastic pyrolysis oil (PPO)can be used as fuel in factories such as boiler plants, glass factories, brick factories, and gypsum plants. For higher-value applications, it can be further processed into diesel fuel using DOING distillation equipment for use in diesel generators or heavy machinery such as trucks, ships, and tractors.

Recovered carbon black (RCB): Recovered carbon black(RCB) can be reused in building materials or rubber production.

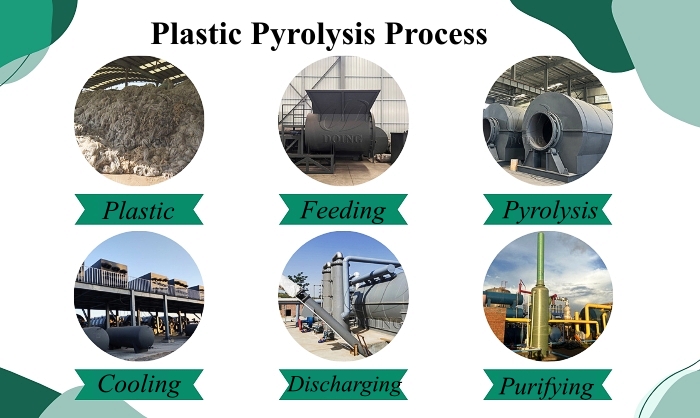

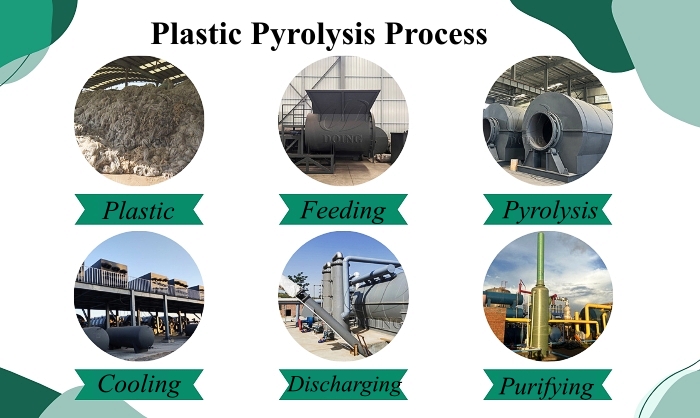

DOING waste plastic pyrolysis equipment workflow advantages

3.Market adaptability: The pyrolysis process is suitable for operations of all sizes, from small mobile units to industrial plants. It offers rapid return on investment, making it scalable for various business models.

As a trusted manufacturer of waste-to-fuel recycling equipment, DOING offers a range of pyrolysis machine tailored for companies seeking reliable making fule from plastic waste production line: batch (frame and conventional)/semi-continuous/fully continuous. Each type of pyrolysis equipment integrates proven TCC principles with user-centric design. Each system ensures stable performance, easy operation, and compliance with environmental standards.

DOING making fuel from plastic waste pyrolysis processing types

DOING pyrolysis equipment utilizes a thermochemical conversion process of making fuel from plastic waste, comprising 3 core steps, each crucial to product quality and efficiency.

The first step is feeding. Feeding can be done manually or by machine. Manual feeding only requires two workers to operate, and the time is about 1.5 to 2 hours, which can fill a plastic pyrolysis reactor with a daily processing capacity of 12-15ton. DOING can recommend a customized machine feeding solution based on your raw material conditions.

The second step is pyrolysis. After the feeding is completed, the burners need to be opened to heat the DOING plastic pyrolysis reactor. It will evaporate the water and breake the molecular structure in the waste plastic. Next the temperature will gradually increase to 200 degrees. Making fuel oil gas from plastic waste by controlling the burners to maintain the temperature between 230 and 260 degrees, this stage lasts for 4 hours.

The third step is the product separation. The oil and gas are converted into plastic pyrolysis oil (PPO) to the maximum extent possible through the DOING condensation system, while non-condensable gases and recoverable carbon black are also collected separately. DOING can recommend product cooling and collection devices based on your investment budget, cooling efficiency, installation, and maintenance requirements.

DOING making fuel from plastic waste pyrolysis processing steps

Thermochemical conversion (TCC) via pyrolysis is the optimal solution for making fuel from plastic waste, addressing both environmental challenges and business profitability. DOING 14+ years of experience in TCC pyrolysis equipment manufacturing ensures reliable, scalable, and cost-effective. Contact DOING today to get a tailored TCC plastic-to-fuel solution, and start your profitable, eco-friendly waste recycling business.

Inquiry more thermochemical conversion (tcc) process of making fuel from plastic waste information

Leave a message in the below form to get more information about pyrolysis plant project, our engineer will contact you ASAP to analysis pyrolysis plant project cost for you.

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd