Industry news / DATE:2025/10/10

As global demand for sustainable energy grows, pyrolysis technology has emerged as a key solution for converting waste plastics/tires/oil sludge into valuable liquid fuel (pyrolysis oil) that can be used as alternative fuels for boilers, generators, or diesel refining. Central to its success is the quality of the resulting pyrolysis oil, which impacts combustion efficiency, equipment durability, safety, environmental compliance, and market value. Poor-quality oil can lead to engine blockages, increased maintenance costs, and even violations of environmental regulations. This article will guide you in evaluating pyrolysis oil quality through physical properties and chemical composition.

Physical Properties:

1.Color: High-quality pyrolysis oil (from tires or plastics) should be transparent to slightly translucent, with colors ranging from amber to dark red. Darker oils with inconsistent color might indicate poor-quality production or contamination during the process.

2.Density: For tire/plastic pyrolysis oil, density should be 0.82–0.88 g/cm³. Pyrolysis oil with a density above 0.9 g/cm³ has a high content of heavy hydrocarbons, resulting in incomplete combustion and leaving residue in the boiler. Pyrolysis oil with a density below 0.8 g/cm³ has a high content of light volatile fractions, which increases the risk of fire during storage and transportation.

Applications of pyrolysis oil

3.Viscosity: Viscosity refers to the thickness of the oil and is crucial for ensuring smooth combustion and preventing blockages in fuel systems. Pyrolysis oil should have a viscosity of 10-25 cSt (centistokes) at 40°C. Tire pyrolysis oil is typically 15-20 cSt, and plastic pyrolysis oil is typically 10-15 cSt. High viscosity may indicate incomplete pyrolysis, requiring higher temperatures for combustion.

4.Flash Point Chemical: The flash point is the minimum temperature at which the oil produces enough vapor to ignite. For industrial applications, the flash point should be greater than 55°C to ensure safety during storage and handling. Oils with a flash point below 40°C are highly flammable and pose a safety hazard.

Chemical Properties:

1.Moisture Content: The moisture content of pyrolysis oil should be <0.5% by weight. High moisture content (>1%) can cause foaming in boilers, incomplete combustion, and frequent maintenance issues such as filter clogging.

2.Sulfur Content: Sulfur content should be <0.5% sulfur. High sulfur content can contribute to harmful emissions during combustion and can also corrode engine parts, leading to costly repairs.

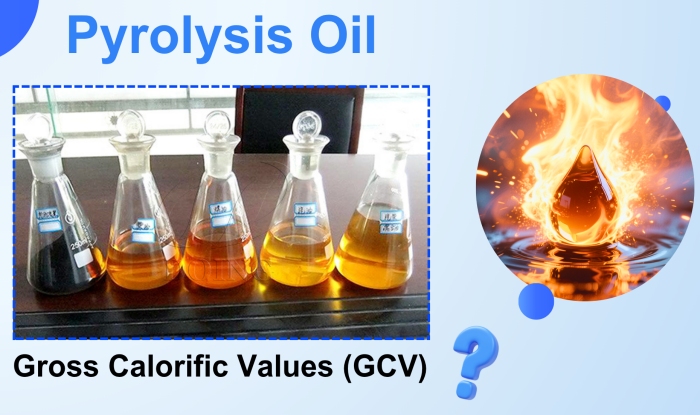

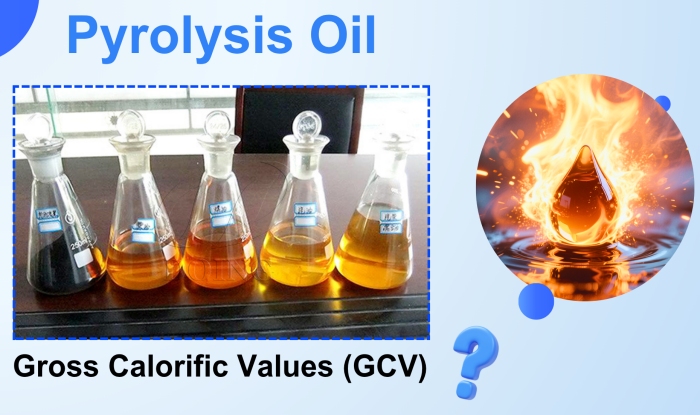

Characteristics of pyrolysis oil

3.Ash Content: Ash content should be <0.1% (by weight). >0.3% means the oil was poorly filtered during production—unsuitable for engines or precision boilers.

4.Energy Content (Heating Value): The energy content, or calorific value, of pyrolysis oil is a key factor in its combustion efficiency. High-quality tire/plastic pyrolysis oil has a calorific value of 42–45 MJ/kg—comparable to commercial diesel (45 MJ/kg) and far higher than coal (25–30 MJ/kg).

How DOING Waste Recycling Pyrolysis Machine Ensures High-Quality Pyrolysis Oil

1.DOING pretreatment process reduces moisture content to <0.5%, preventing issues such as foaming and incomplete combustion.

2.DOING pyrolysis reactor ensures uniform heating, preventing the accumulation of heavy hydrocarbons (resulting in high density) or an excess of light fractions (low density).

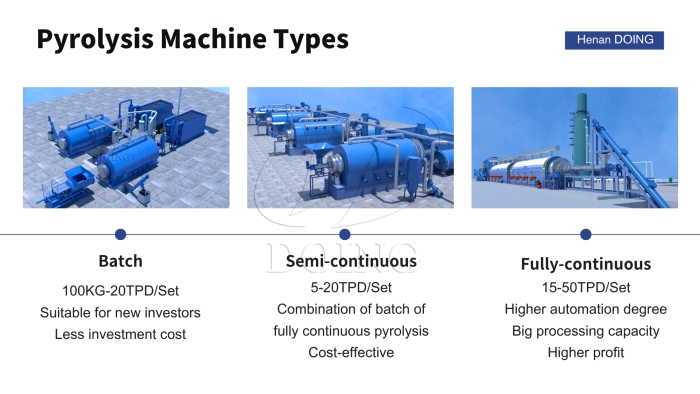

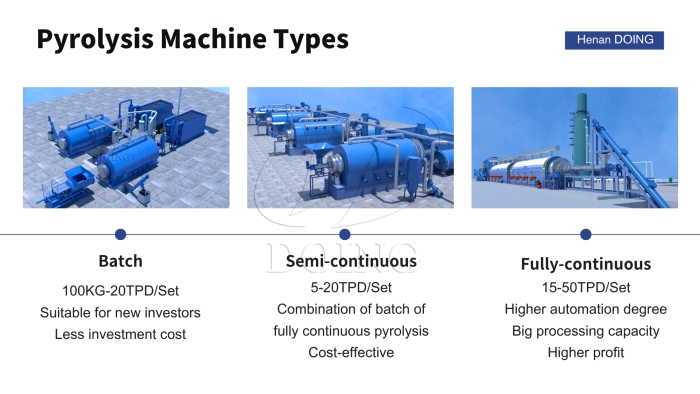

DOING three types pyrolysis machine

3.DOING shell-and-tube condenser optimizes cooling process, ensuring complete condensation of steam and preventing viscosity spikes that can affect the quality of the oil.

4.DOING PLC system controls the pyrolysis reactor's precise temperature control to prevent over-cracking, which can produce highly flammable light fractions and lower the flash point.

5.DOING distillation machine improves the quality, color, and odor of pyrolysis oil through filtration, purification, decolorization, and deodorization, converting it into diesel for a wider range of applications, such as diesel generators, trucks, tractors, ships, and other heavy machinery.

DOING pyrolysis oil distillation machine

Evaluating the quality of pyrolysis oil involves assessing both physical and chemical properties, each of which plays a crucial role in its performance and safety. By understanding these characteristics and using advanced technologies like those in DOING waste recycling pyrolysis machines, you can ensure the production of high-quality pyrolysis oil that meets safety regulations, reduces maintenance costs, and provides an efficient alternative energy source.

For more information on how our state-of-the-art pyrolysis machines can help you produce high-quality pyrolysis oil, contact us today!

Inquiry more how to evaluate the quality of pyrolysis oil? information

Leave a message in the below form to get more information about pyrolysis plant project, our engineer will contact you ASAP to analysis pyrolysis plant project cost for you.

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd