Industry news / DATE:2025/8/19

Is oil-based mud a hazardous material? Yes, oil-based mud (OBM) —a drilling fluid used in oil and gas operations, which is generally classified as a hazardous material in most regions. This classification is based on specific characteristics and regulatory standards.

DOING oil-based mud pyrolysis machine

Oil-based mud (OBM) contains a large amount of harmful substances, such as heavy metals, petroleum substances, chemical additives and rock cuttings, hydrocarbons, and volatile organic compounds (VOCs)etc. If discharged directly, it can cause severe damage to the ecological environment. Therefore, the treatment of oil-based mud should follow the principles of reduction, harmlessness and resource utilization. As a provider of equipment deeply engaged in the environmentally friendly recycling of solid waste, hazardous waste feedstocks, etc., DOING has sustainable treatment solutions for oil-based mud (OBM).

Characteristics of oil-based mud (OBM)

1. Complex composition and high toxicity

Oil-based mud (OBM) contains base oils (e.g., mineral oil, diesel, or synthetic oils), weighting agents (e.g., barite, galena), and additives (e.g., emulsifiers, corrosion inhibitors). Many of these components—such as certain petroleum-based oils or heavy metals in weighting agents.

2. High pollution risk

The petroleum-based oils in oil-based mud (OBM) biodegrade slowly. Excessive levels of heavy metals (such as barium, chromium, and lead) can lead to soil desertification, geological damage, and damage aquatic ecosystems if leaked or improperly disposed of.

3.Flammability Risks:

Most base oils in OBM are flammable (especially diesel-based formulations), creating fire or explosion hazards during storage, transportation, or on-site use (e.g., in oil and gas drilling operations).

DOING oil-based mud pyrolysis machine advantages

Therefore, the traditional oil-based sludge mud treatment method of direct landfilling is no longer applicable. DOING oil-based mud pyrolysis machine offers a solution to mitigate these hazards while creating value. Designed to process oil-based mud(OBM) efficiently, it uses thermal decomposition in an oxygen-free environment to break down hazardous components into:

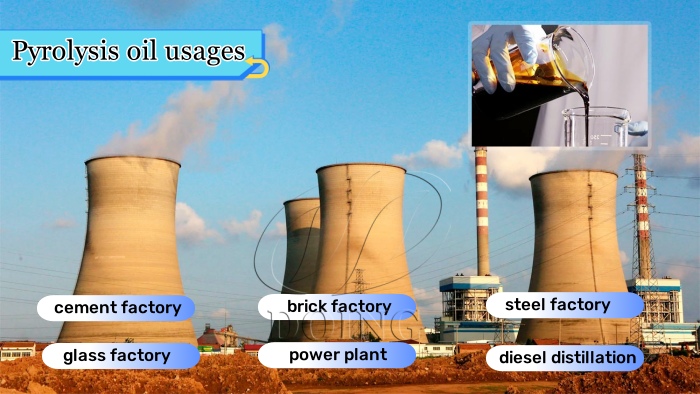

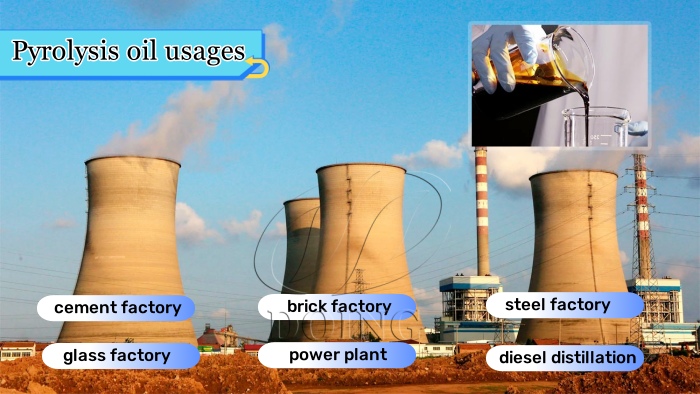

1.Pyrolysis oil:

A high-quality oil similar to industrial fuel oil. This oil can be used directly as a fuel in industrial burners, heavy oil generators or be further refined into higher-value dieselfor heavy machine and diesel generators.

2.Solid residue:

The solid residue, after being cooled and processed, is a sterile, inert carbon black. This material can be used as a reinforcing agent in the rubber industry, as a pigment in inks, or as a construction material additive, ensuring that no waste is left behind.

3.Syngas:

A combustible gas mixture (mainly methane, hydrogen, and carbon monoxide) that is recycled back into the system to fuel the pyrolysis reactor.

DOING oil-based mud pyrolysis oil application

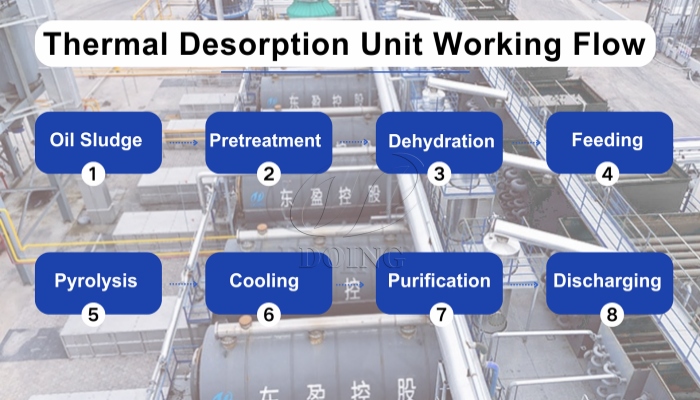

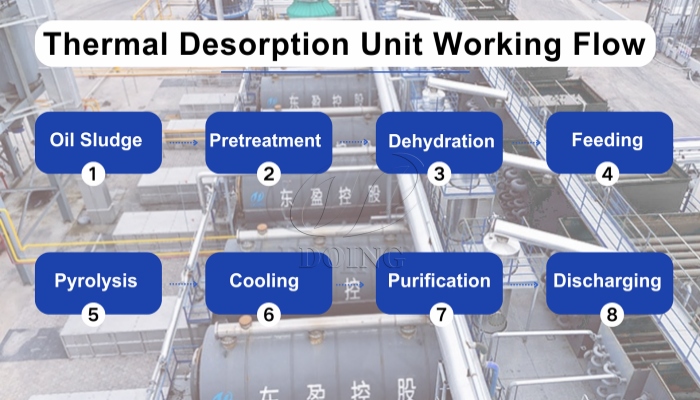

Treatment Process of DOING oil-based mud pyrolysis machine

Petroleum drilling mud is converted into oil and tailings by the DOING pyrolysis technique. The flow of the oil -based treatment process is as follows;

1.Feeding the oil-based mud:

Oily sludge is delivered to the feeding end of the pyrolysis furnace via a sealed discharge valve and a screw-squeezed conveyor, where preheating, distillation and pyrolysis begin.

2.Pyrolysis the oil-based mud:

The pyrolysis temperature is between 200 and 550℃, during which the light oil components in the oily sludge are distilled and the heavy oils are decomposed into volatile low-carbon hydrocarbon fuels, liquid fuels, and solid carbon, etc. After high-temperature pyrolysis reaction, oil-based mud mainly produces three types of substances, namely, recoverable oil and gas, water vapor, non-condensable combustible gas (non-condensable gas), carbon residue and inorganic solid particles.

3.Oil and gas condensate separation:

A mixture of recoverable oil and gas and non-condensate flammable gas enters the condensate from the buffer tank.Under the condensation effect of the heat exchanger, recoverable oil and gas become liquid oil and enter the oil storage system together with non-condensable flammable gas..Liquid oil, after filtration, enters the oil storage system, and flammable gas, after passing through water seals, enters the combustion system to replenish the heat required by the hot air combustion system.

4.Solid Slag Transportation and Flue Gas Purification and Emission:

After pyrolysis, solid material containing tailings and other residues is transported out of the system through a slag discharge sealing system after being cooled and thermally exchanged..The flue gas produced by combustion in the pyrolysis furnace is delivered and dust removed by an enhanced spray absorption tower and cooled simultaneously..It is then fully deodorized, decomposed and purified by UV equipment before being discharged to standard.

DOING oil-based mud pyrolysis machine working process

Thus, it can be seen that oil-based mud is usually classified as hazardous the oil-based mud due to its flammability, toxicity and environmental risks. However, through pyrolysis technology, oil-based mud can be transformed from a "pollution source" into a "resource pool". If you have any related needs for recycling solid waste (rubber tire, plastic, biomass, etc.) or hazardous waste (drilling oil sludge/coal tar residue related products), please contact DOING for further communication.

Inquiry more is oil-based mud a hazardous material? how to treat it? information

Leave a message in the below form to get more information about pyrolysis plant project, our engineer will contact you ASAP to analysis pyrolysis plant project cost for you.

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd