Industry news / DATE:2025/6/26

As the construction industry expands, the amount of waste generated has become significant, creating both environmental and economic challenges. Driven by both policy and technology, these construction wastes are undergoing a magnificent transformation - 30% to 40% of the light combustible materials are being converted into high calorific value fuels, becoming the "black gold" that cement plants and power plants are vying for.

DOING construction waste to fuel pyrolysis plant

Construction waste is complex in composition, mainly consisting of two types of substances: one is inorganic materials such as concrete, bricks, glass, and metal that cannot be pyrolyzed, which usually require other methods for recycling, such as crushing, melting or reprocessing. And the other is organic combustibles such as plastic,rubber, and wood that can be pyrolyzed. Data shows that the proportion of combustibles in construction waste that can be pyrolyzed is as high as 30% to 40%, and these organic substances can be decomposed into fuel oil, carbon black, charcoal, wood vinegar under high temperature and oxygen-free conditions. The following are the main types and their characteristics:

1.Plastic Waste: Construction waste often includes plastic materials like construction plastics (pipes, formworks, packaging materials), plastic films, foam insulation (e.g., polystyrene)

2.Rubber Waste: Rubber seals, gaskets, and discarded tires from construction-related equipment.

3.Wood Waste: Solid wooden beams and columns from building demolition, door and window frames, unpainted wooden formwork, and debris from wood cutting and grinding, such as sawdust, wood chips, and wood powder.

Waste pyrolysis product and application

DOING GROUP, a supplier of environmental equipment for converting waste into effective resources, proposes to process such waste using pyrolysis plant, equipped with its patented products (safety device, environmental device) to effectively remove pollutants and convert it into RDF in an environmentally safe manner. The characteristic of this fuel is its high calorific value, which is 10,592.48 Kcal/kg. It can be used as an alternative fuel in cement plants, glass plants, steel plants, boilers, etc. While the carbon black residue can be utilized in the manufacturing of new tires, rubber products, or even in the production of inks. The charcoal generated by carbonization equipment can be used as fuel and fertilizer, wood vinegar can be used for soil improvement, deodorization, food preservation, tar can be used as fuel and waterproof material, raw material of carbon black.

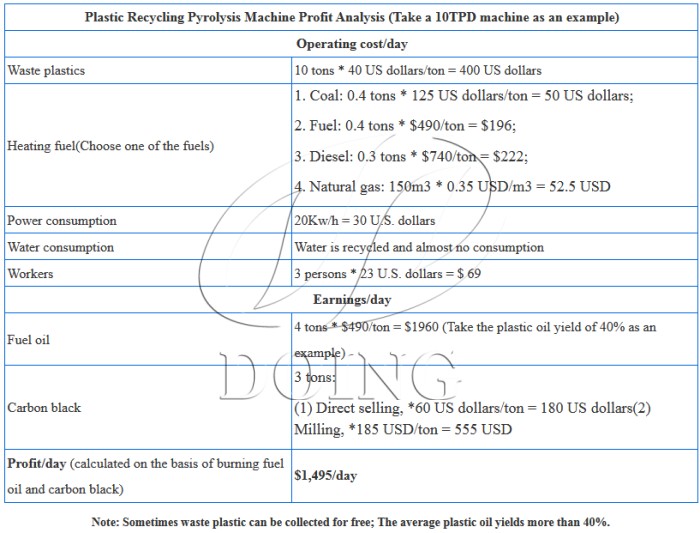

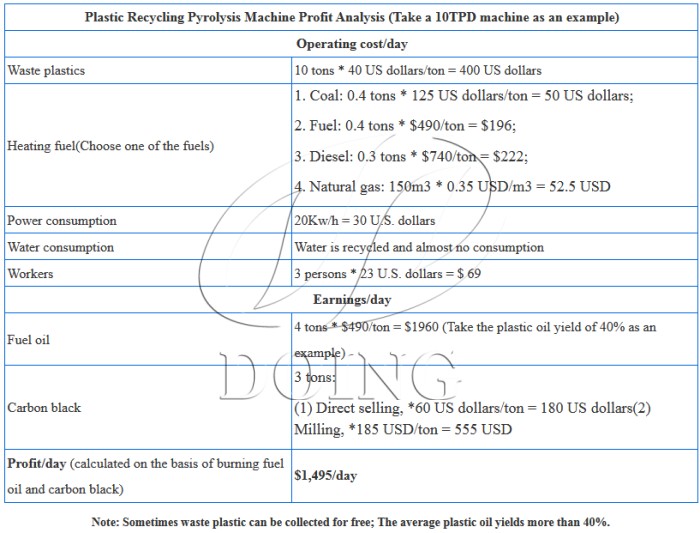

Profits table of plastic pyrolysis

It can be seen from this that the resource utilization of construction waste is not only an environmental protection issue but also an economic proposition. When a discarded rubber or a piece of plastic packaging can be transformed into clean energy, companies can reduce waste disposal costs and create valuable resources, and can sell these fuels and carbon black to make profits.

DOING not only resolves the predicament of " The city is drowning in MSW ", but also paves the way for green economic growth. If you want to know more informationabout construction waste pyrolysis recycling and DOING GROUP advanced pyrolysis plant technology, you are warmly welcome to visit the DOING factory and witness the magic of waste - to - resource transformation firsthand.

Inquiry more what kind of construction waste can be recycled by pyrolysis? information

Leave a message in the below form to get more information about pyrolysis plant project, our engineer will contact you ASAP to analysis pyrolysis plant project cost for you.

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd