Industry news / DATE:2025/5/15

With millions of waste tyres generated globally each year, setting up a tyre recycling plant offers both environmental and economic benefits, all final products can be sold to the market for making profits. Among many waste tire recycling businesses, pyrolysis of waste tires into fuel oil, carbon black, steel wire, etc. is very popular and profitable.

However, establishing such a tyre recycling plant requires careful planning and consideration of various factors. This article will walk you through the crucial steps involved in setting up a successful tyre recycling plant and introduce you about the features of DOING top-notch waste tyre recycling pyrolysis plants. What preparations are needed to do in advance?

Step 1. Market Research and Planning

Analyse the waste tyre generation volume in your area, identify potential clients for the end - products like tyres pyrolysis oil and carbon black, and evaluate the local regulations on tyre recycling. This groundwork helps you create a feasible business plan, including cost estimation, revenue projection and return on investment analysis.

Application of tyre pyrolysis product

The produced pyrolysis oil from waste tire is the main end product, mainly used as the industrial heating fuel for boiler factory, glass factory, cement factory and steel mill, etc. Carbon black is the second main product from pyrolysis plant, which can be used as heating fuel after processing into briquettes, and can also used for rubber factory and painting factory after further processing. Steel wire can be sold as scrap or remelted into new products for sale.

Step 2. Site Selection and Planning:

Consider factors such as proximity to tyre sources, transportation infrastructure, access to utilities, and environmental regulations. And the site should have enough space for the plant and comply with local regulations regarding waste management and environmental impact. DOING waste tyre recycling pyrolysis plants occupy an area of about 200~ 500 square meters.

DOING waste tyre recycling pyrolysis plants site

DOING waste tyre recycling pyrolysis plants site

Step 3. Obtain Necessary Permits and Licenses

To operate a tyre recycling plant legally, you need to obtain the required permits and licenses from local and national authorities. These may include environmental permits, business licenses, waste handling permits, and safety certifications. Complying with regulatory requirements is essential to avoid legal issues and ensure the long-term sustainability of your business.

Step 4. Invest in Quality waste tyre recycling pyrolysis plants

The heart of a tyre recycling plant is its equipment. Investing in high-quality waste tyre recycling pyrolysis plant is crucial for efficient and profitable operations. DOING, a leading manufacturer in the industry, offers state-of-the-art waste tyre recycling pyrolysis plants that are designed to deliver exceptional performance and reliability.

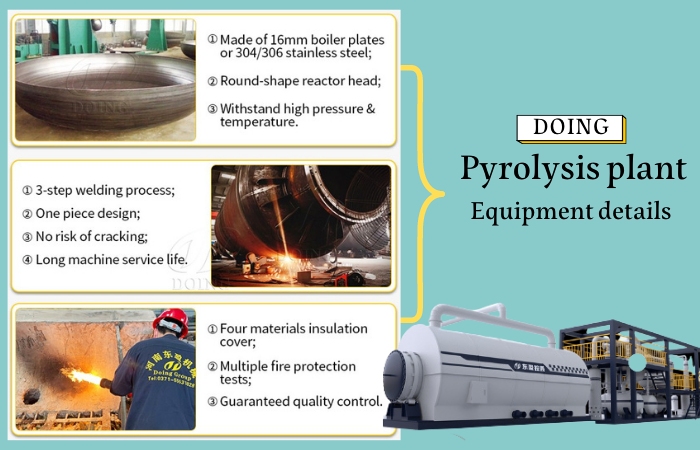

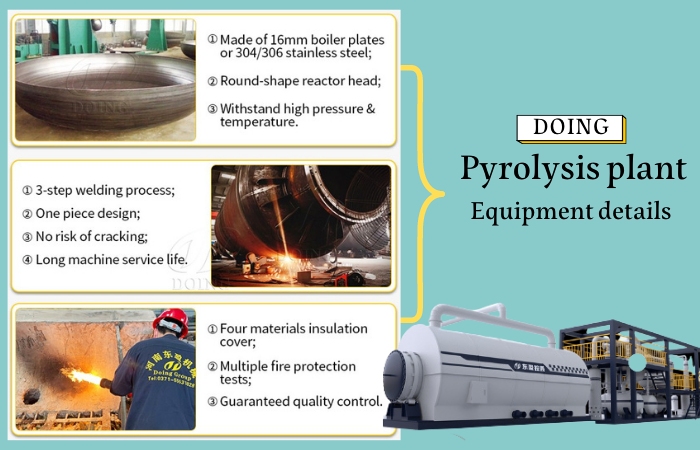

DOING waste tyre recycling pyrolysis plants advantages

Features of DOING waste tyre recycling pyrolysis plants

1.High Efficiency: DOING waste tyre recycling pyrolysis plants equipped with advanced technology that maximizes the conversion of waste tyres into valuable products. With a high oil yield and fast processing speed, these machines can significantly increase your plant's productivity and profitability.

2.Environmental protection: DOING waste tyre recycling pyrolysis plants equipped with an advanced pollution control system to ensure that the emission of harmful substances is within the permitted range. A circulating water system is configured to reduce the generation of wastewater.

3.Low energy consumption: DOING waste tyre recycling pyrolysis plants with an energy-saving design, the flammable tail gas generated during the pyrolysis process is used as reactor fuel, which not only reduces your operating costs but also minimizes the impact on the environment.

4.Durability: DOING waste tyre recycling pyrolysis plants is built with durable materials such as Q245R and Q345R steel and can also be customized with stainless steel to ensure long-term stability and corrosion resistance.

5.User-friendly design: DOING designed with full consideration of user convenience. Design DOING waste tyre recycling pyrolysis plants with various processing capacities to meet the needs of different customers, and configure a PLC control system for easy operation and monitoring.

DOING waste tyre recycling machine

Note: Considering the different feeding requirements of different types of tyre recycling pyrolysis plant, DOING also provides a series of tyre pre-processing equipment, such as tyre wire drawing machine, tyre bead cutting machine, tyre cutting machine, tyre shredder, tyre to rubber powder processing equipment, etc.

Step 5. Installation and Training:

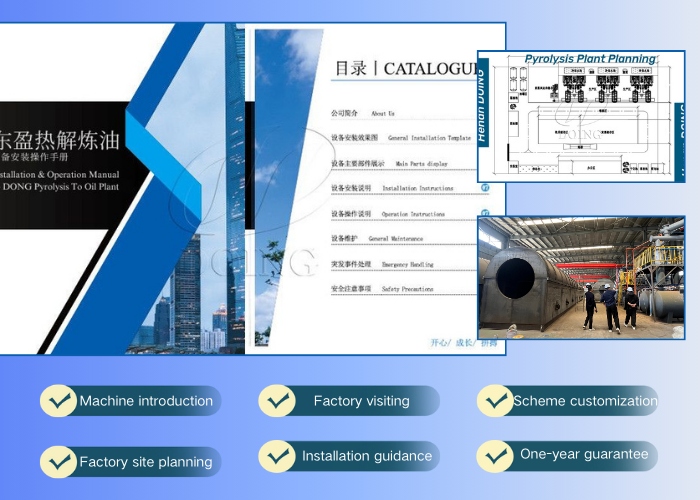

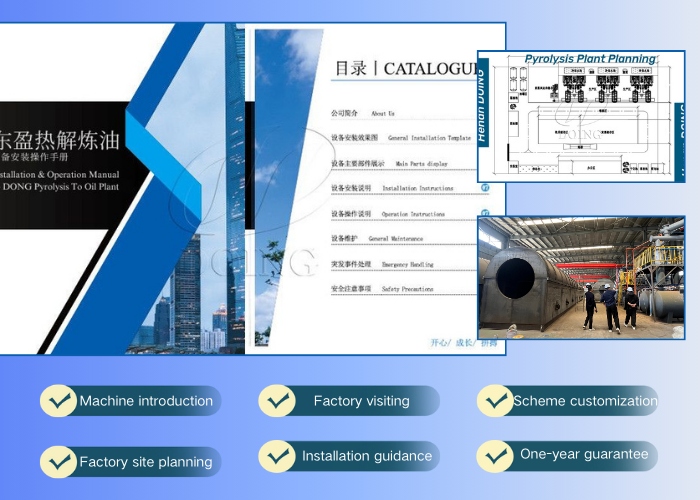

After purchasing DOING waste tyre recycling pyrolysis plants, installation can be done by DOING experienced technicians. Training is also provided to help operators understand the process, troubleshoot potential issues, and ensure smooth operations.

Step 6. Operations and Maintenance:

Once DOING waste tyre recycling pyrolysis plants is operational, regular maintenance is crucial to keeping everything running smoothly. This includes cleaning the system, checking for leaks, and replacing worn-out components.

DOING provide complete service

In conclusion, setting up a tyre recycling plant requires careful planning, investment in quality equipment, and compliance with regulatory requirements. By following the steps outlined in this article and choosing DOING waste tyre recycling pyrolysis plants, you can establish a successful and sustainable tyre recycling business and gain profits. Contact DOING today to learn more about our innovative waste tyre recyclinf solutions.

Inquiry more how do you set up a tyre recycling plant? information

Leave a message in the below form to get more information about pyrolysis plant project, our engineer will contact you ASAP to analysis pyrolysis plant project cost for you.

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd

DOING waste tyre recycling pyrolysis plants site

DOING waste tyre recycling pyrolysis plants site