Industry news / DATE:2025/4/29

Waste oily sludge is a byproduct generated from various industrial processes such as oil refining, petrochemical production, and oil storage. It contains a high concentration of oil, heavy metals, and toxic organic substances, posing a serious threat to the environment and human health if not treated properly.

Traditional methods of treating waste oily sludge, like landfilling and incineration, have many drawbacks. Landfilling can cause soil and groundwater pollution as the harmful substances in the sludge gradually seep out. Incineration, on the other hand, may release a large amount of harmful gases into the atmosphere, contributing to air pollution.

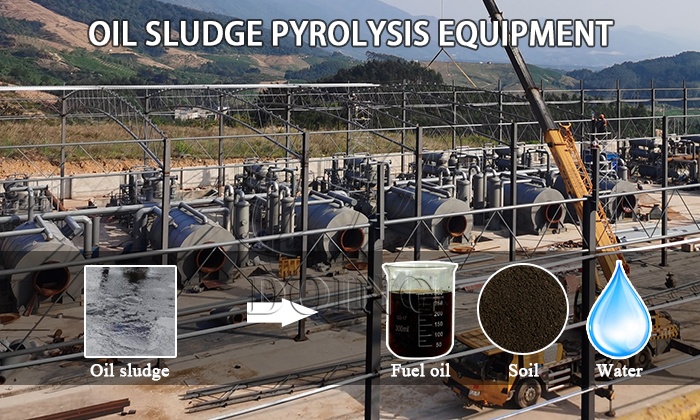

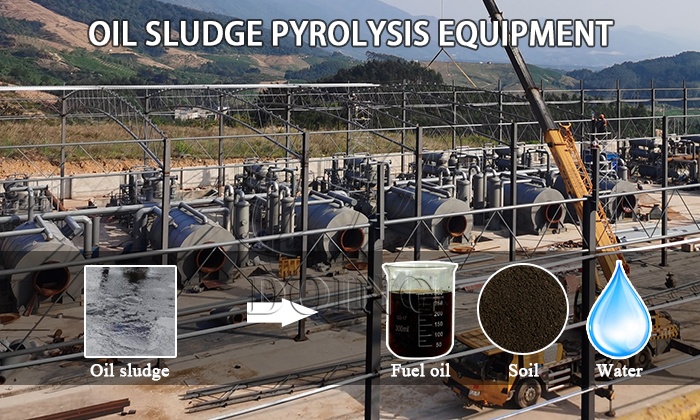

DOING waste oily sludge pyrolysis machine

One of the most innovative and environmentally friendly methods for treating waste oily sludge is pyrolysis. The waste oily sludge pyrolysis machine designed by DOING involves heating the waste oily sludge in an oxygen-free environment, causing it to break down into valuable byproducts such as oils, gases, and residue. These byproducts can be further processed for energy recovery or other industrial applications, making pyrolysis an ideal solution for recycling waste oily sludge.

Today I am introducing how to effectively treat waste oily sludge with DOING pyrolysis machine.

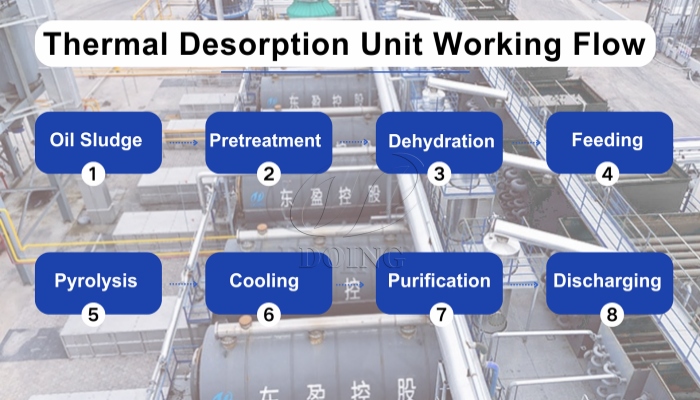

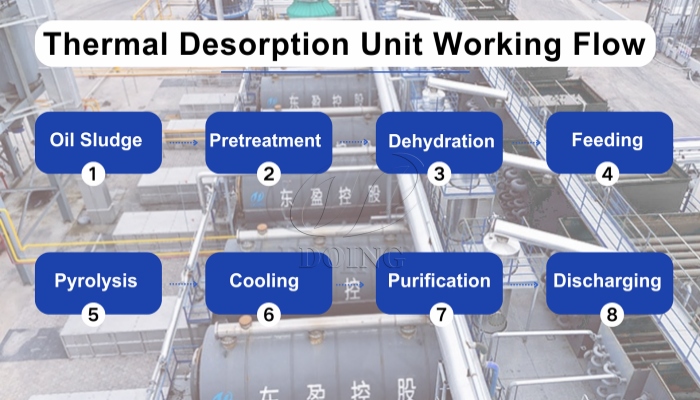

1.Pretreatment of waste oily sludge

Dehydration and impurity removal: removing water and solid impurities (such as mud, metal fragments, iron filings ) from ground sludge, tank bottom sludge, refinery sludge, oil-based rock cuttings, steel sludge, etc. by sedimentation, centrifugation or filtration to reduce the subsequent cracking energy consumption.

Drying: reducing the water content of waste oily sludge to below 10% (usually using drying equipment) to improve cracking efficiency.

2.Pyrolysis waste oily sludge

Charge: feeding the pretreated waste oily sludge into the DOING pyrolysis machine, seal the DOING pyrolysis machine using oxygen-free closed pyrolysis technology. For more efficient pyrolysis, we recommend using a semi-continuous DOING waste oily sludge pyrolysis machine with sealed auger feeding.

Heating pyrolysis: the operator should control the burner, gradually and slowly heat to 300~500℃, and maintain the high temperature for 7-8 hours to fully pyrolysis the waste oily sludge.

3.Product collection and separation

Oil and gas condensation: high-temperature oil and gas are cooled into liquid oil through the condensation system. This product pyrolysos oil is heavy fuel oil, which is suitable for factory boiler combustion. And can be further refined and used in heavy machine as fuel.

Combustible gas recovery: non-condensable combustible gas enters the reactor furnace through the tail gas pipeline, ignites through the tail gas burner, and is used to heat the DOING waste oily sludge pyrolysis machine to reduce energy consumption.

Solid residue treatment: Residual coke or inorganic matter (about 5%~20%) can be incinerated or used as raw materials for building materials.

Process of treating waste oily sludge process effectively

DOING waste oily sludge pyrolysis machine is not only efficient and of good quality, but also environmentally friendly, easy to operate and maintain. It is a waste oily sludge treatment equipment worthy of customer trust. DOING waste oily sludge pyrolysis equipment has been installed and operated in Colombia, Brazil, China, Malaysia, and Canada. If you are looking for an effective waste oily sludge treatment solution, DOING waste oily sludge pyrolysis machine is definitely worth considering, welcome to contact us.

Inquiry more how do you treat waste oily sludge? information

Leave a message in the below form to get more information about pyrolysis plant project, our engineer will contact you ASAP to analysis pyrolysis plant project cost for you.

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd