The capacity of pyrolysis machines on the market varies in size. DOING is a professional manufacturer and supplier of pyrolysis machines, which also has developed pyrolysis machines with different capacities in order to meet the different needs of different customers. From 100kg to 50tons, various capacities and types are available.

There are three types of pyrolysis machines of DOING company: continuous type, semi-continuous type and batch-type pyrolysis machine.

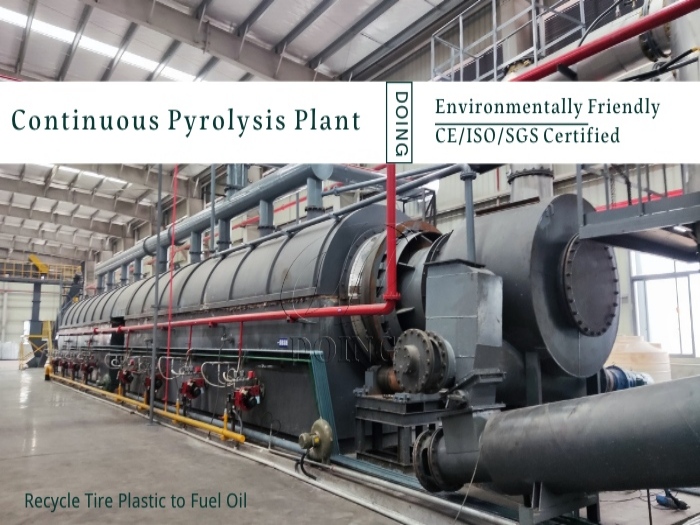

DOING continuous type pyrolysis machine

Continuous pyrolysis machine is more suitable for large processing capacity, its capacity has 15tons, 20tons, 30tons, 40tons, 50tons. DOING continuous type adopts PLC fully automatic system, which is very suitable for customers who need large capacity and local labor is expensive.

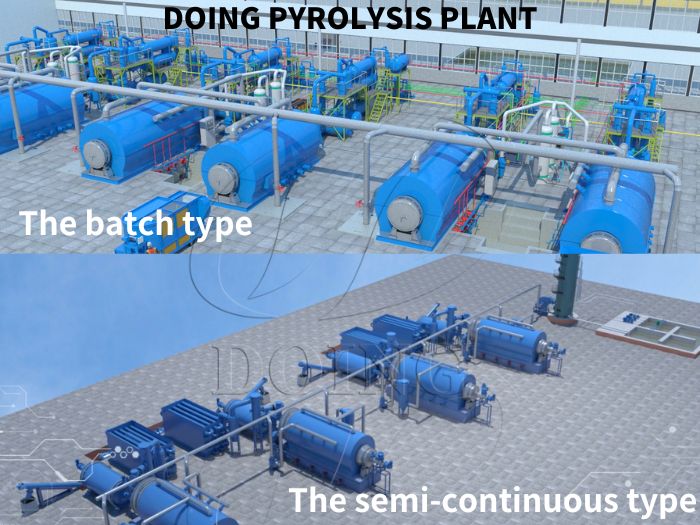

The processing capacity of DOING semi-countinuous pyrolysis machine is 10tons, 15tons, 20tons, which is more suitable for people who need a high degree of automation but don't have a lot of budget. The automation degree of semi-continuous type is higher than the batch type, but not as good as the full continuous.

DOING semi-continuous & batch type pyrolysis machine

The batch pyrolysis machine's capacity range is from 100kg -20tons, including 100kg, 500kg, 1tons, 2tons, 5tons, 10tons, 15tons, 18tons, 20tons. Batch type capacity options are the most and can meet the needs of most customers. If you are just engaged in the pyrolysis industry of waste tires, plastics, and oil sludge and have a small budget, then you can choose from a capacity below 5 tons. Then you can slowly expand the scale of the pyrolysis plant, choose a pyrolysis machine with a capacity of 10tons-20tons.

DOING batch type pyrolysis machine

Besides, the continuous type has high requirements on raw materials, such as waste tire, which needs to process the tire into rubber powder. Relatively speaking, the batch type does not have high requirements on raw materials, and the whole tire can be put into the pyrolysis reactor. If you want to omit the pretreatment steps of raw materials, you can choose our batch type pyrolysis machines.

Each type of pyrolysis machine has its own characteristics and advantages. When choosing a pyrolysis machine, not only the capacity, but also the budget and post-operation cost should be considered. Therefore, there is no best pyrolysis machine, only the most suitable pyrolysis machine for you. If you are interested in our pyrolysis machine, you can consult us at any time. Our sales manager will customize the most suitable pyrolysis machine for you according to your actual situation.