DOING Holdings is a top manufacturer of waste oil recycling to diesel plants in China. Our waste oil distillation plant could be used to recycle the waste engine/motor/lube oil to diesel fuel. And there are different configurations that can be chosen. Let us introduce the new design waste oil to the diesel fuel process for you.

DOING waste oil recycling to diesel plant

1. Heating

There is a dual heating system equipped with our waste oil to diesel plant, heat conduction oil furnace preheating system and reactor heating system, which is more efficient and saves time.

① Preheating: Heating the heat-conducting oil in the heat-conducting oil furnace takes about 2 hours.

② Heating: Heating the reactor by burners, this step can be carried out simultaneously with preheating or after preheating.

2.1 Cooling

When the waste oil in the reactor is heated to about 250 ℃, then some emulsifiable concentrate in the waste oil will be turned into oil gas.

The oil-gas of emulsifiable concentrate will turn into diesel fuel after cooling system. Our cooling system consists of vertical condensers and horizontal condensers. And these tube condensers can greatly increase the cooling area, so that the cooling effect is sufficient and the oil output is high.

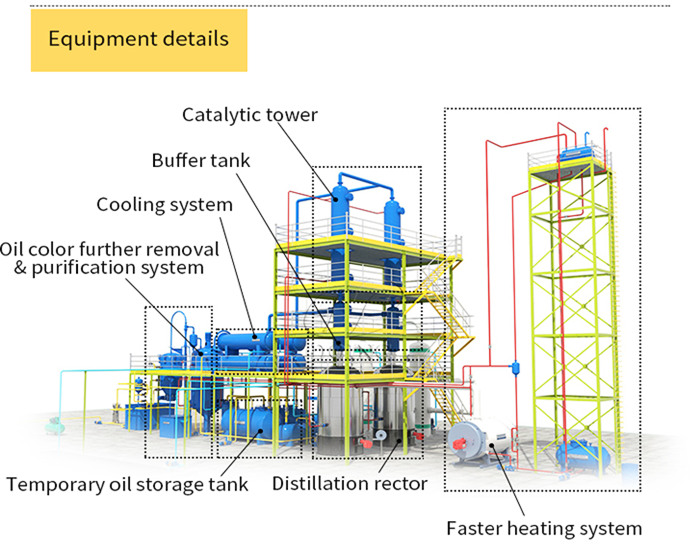

The details of DOING waste oil distillation plant

2.2. Purification & Cooling

① When the temperature exceeds 250 ℃, the remaining waste oil will be oil-gas and enter into the catalytic system. After the catalytic system, the waste oil-gas will be distilled into diesel oil-gas. In our catalyst system, there are two kinds of catalyst, catalyst A and catalyst B, they all can all be recycled.

② The diesel oil-gas will be cooling into diesel after our cooling condensers.

3. White clay purification system & Filter system(Optional device)

The white clay purification system can make the color of diesel fuel look brighter, and the filter system will filter the white clay.

4. Storage

Then the diesel fuel can be stored in the oil tank.

The disel obtained from DOING waste oil distillation plant

The above is the introduction of waste oil to diesel fuel process. Our waste oil to diesel plants adopts solid catalysts, and the catalysts can be purchased directly from our company, saves the time of purchase and is more convenient for customers. If you are interested in our waste oil distillation plant, you can contact us at any time.