Plastic to fuel conversion process

Waste plastic is a potential resource for human to use. After proper disposal, plastic can be precious in some way. Doinggroup Plastic to fuel conversion process machine is the right plant of doing this. It converts plastic to fuel through a process of pyrolysis. This Plastic to fuel conversion process machine maximizes the value of waste plastic and properly solve the problem of plastic pollution in human world, therefore, it will be a perfect choice for you.

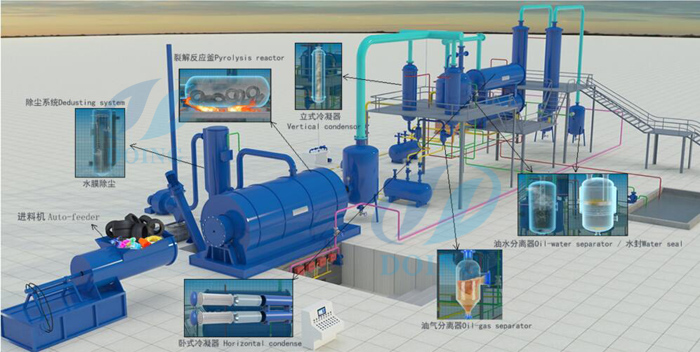

Plastic to fuel conversion process ?

Plastic to fuel conversion process waste plastic to fuel oil and carbon black

1. Pre-treatment: sort and clean the waste plastic to make sure there’s no impurities. Preheat the burning room of the pyrolysis host. If the wastes you collect are not clearly sorted, we recommend you to use a waste sorting machine to do the waste separation.

2. Screw feeder feeds the waste plastic into the pyrolysis reactor automatically. Catalyst is also needed and we suggest activated clay, ZnO and barium hydroxide.

3. Heat the reactor by fuels (wood, fuel oil, coal, LPG or nature gas, etc.) and make sure the interior temperature reach to the requisite degree. When the temperature reaches to certain degree, there will be oil gas and the oil gas will go to the gas manifold.

4. Heavy particles in the gas will be liquefied and reserved in heavy oil tank. Light oil gas will rise to the condenser and then liquefied into light oil being reserved as well.

Plastic to fuel conversion process machine

5. There is also combustible gas generated during the pyrolysis process. The gas will get cleaned and desulfurization in the hydroseal and then be used as fuel to heat the reactor of the pyrolysis machine.

6. Exhausted smoke will be discharged safely. Before that, the smoke will be cooled down in the flue condenser and then be de-dusted. It will also go through de-dusting, washing, water spraying, ceramic ring adsorption and activated carbon absorption and finally meet the EU environmental protection and emission standards.