Converting municipal solid waste, such as plastic, rubber tires, and oil sludge, into fuel through pyrolysis is an excellent way to recycle waste into energy. However, it is crucial to choose a top-quality pyrolysis plant for efficient and controlled processing. If you want to take action and enhance your business, it is essential to obtain a reliable and top-quality pyrolysis plant from a reputable manufacturer.

Allow me to provide guidelines for selecting a top-quality pyrolysis plant manufacturer in China to simplify the process and make it more natural.

Top quality pyrolysis plant for sale

1.Evaluating Experience

Investing blindly carries risks, and you certainly don't want to lose money. Therefore, consider the experience of pyrolysis plant manufacturers and the equipment they specialize in. If you are satisfied with their manufacturing capabilities and quality, proceed to the next step.

Henan Doing Environmental Protection Technology Co., Ltd. (referred to as HENAN DOING) is a leading manufacturer in China dedicated to the research and development of large and medium-sized renewable energy recycling and pyrolysis plants. With excellent products, sincere service, and a good reputation, HENAN DOING has become an industry leader. The company possesses a research institute and a new product experimental base for continuous product development. HENAN DOING's pyrolysis plants have been successfully installed and operated in over 90 countries and regions, including America, Italy, Russia, India, Japan, Macedonia, Iran, Egypt, Mexico, Ecuador, Haiti, Congo, Uganda, the Philippines, South Africa, Nigeria, Pakistan, Thailand, Malaysia, Bangladesh, and Guatemala, etc.

DOING pyrolysis plants project cases all around the world

2.Cost-Effective Equipment Selection

Cost is a crucial factor when planning to purchase a pyrolysis plant, especially a top-quality one. Apart from quality, there are other features that affect the overall cost. Before deciding on a manufacturer, consider the cost-related features.

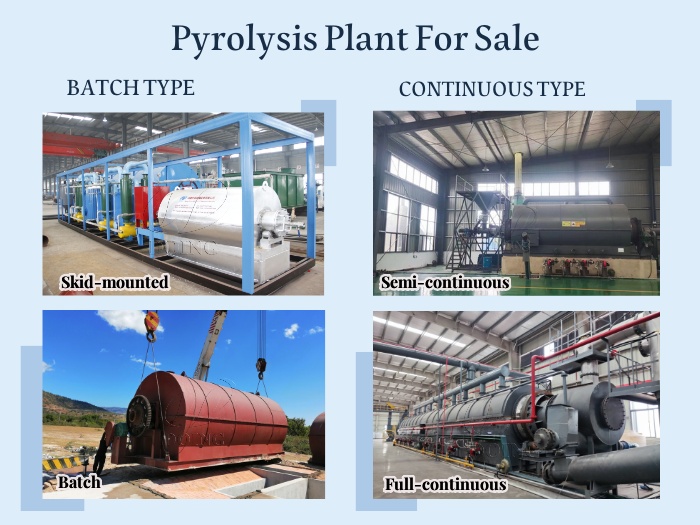

If you are currently analyzing costs, please feel free to contact us with your specific pyrolysis plant configuration requirements. We will develop a comprehensive project feasibility report analysis and ROI analysis for you. Henan Doing provides various types and scales of pyrolysis plants at factory prices, including mini small-scale mobile skid-mounted pyrolysis plants, batch pyrolysis plants, semi-continuous pyrolysis plants, and fully automatic continuous pyrolysis plants.

DOING batch continuous pyrolysis plant for sale

3.How to Compare Pyrolysis Plant Manufacturer?

Before making a purchase decision, evaluate pyrolysis plant manufacturers. With numerous manufacturers claiming to provide the best pyrolysis plants, it is vital to assess their products. Focus not only on price but also on quality, machine design, fabrication details, installation experience, manufacturing facilities, and certificates. Knowing exactly what you need is key to comparing pyrolysis plants effectively.

If you are unsure which Chinese manufacturer can provide a better plant for you, we invite you to visit Henan Doing Environmental Protection Technology Co., Ltd. Meet our professional team, engineers, and technology experts to make an informed decision.

Top pyrolysis plant manufacturer in China Henan Doing Compamy

4.Characteristics of Pyrolysis Plants Produced by Henan Doing Company:

(1)Reliable quality, safety, environmental friendliness, long lifespan, and ease of operation. HENAN DOING's pyrolysis plants are the preferred choice of customers from 90+ countries and regions, and we receive positive feedback from our customers.

(2)We provide process design, installation, commissioning, technical personnel training, and one-stop services with our professional engineering team.

(3)We undertake relocation, technical transformation, and turnkey projects for old factories.

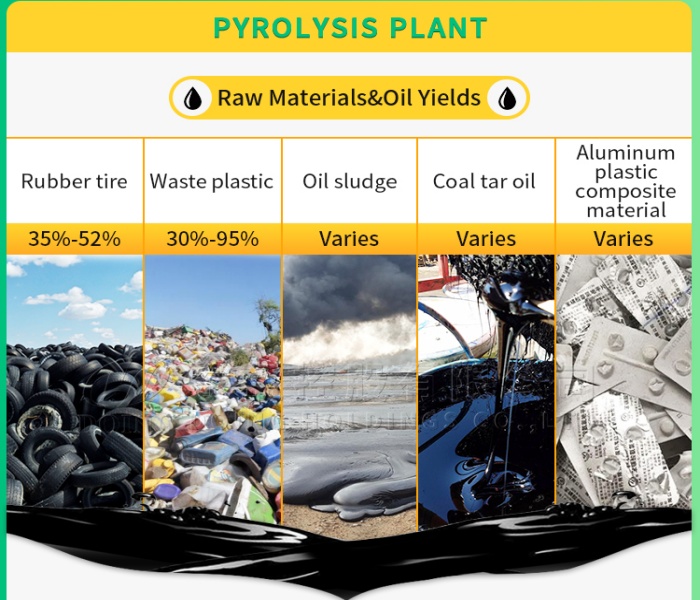

5.Raw Materials Recycled by DOING Pyrolysis Plant

DOING Pyrolysis plants can process various organic municipal solid waste materials, including waste rubber tires, waste plastics, oil sludge, coal tar, aluminum-plastic materials, and more. Our pyrolysis plant extracts fuel oil, carbon black, syn-gas, and steel wire from these solid wastes. Most importantly, the entire pyrolysis process is environmentally friendly and non-polluting.

Recycable raw materials for pyrolysis plants

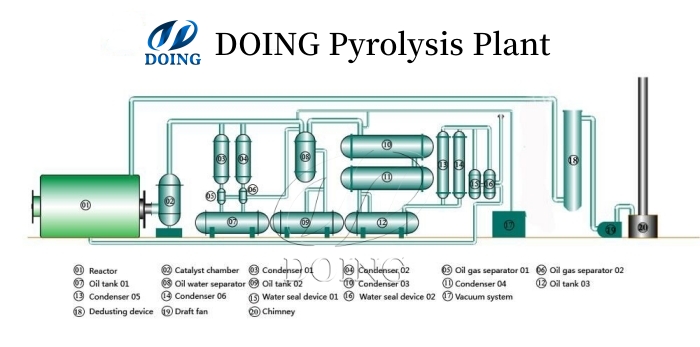

6.Pyrolysis Plant Process: (Using waste tires as an example)

HENAN DOING pyrolysis plant working process is as the follows:

Workflow of pyrolysis plant working process

a) Feeding: This takes approximately 1-2 hours. Tires below 1.4 meters can be directly fed into the plant, while larger tires require cutting before feeding.

b) Heating: Heating takes about 10 hours, with oil gas produced after approximately 2 hours of heating.

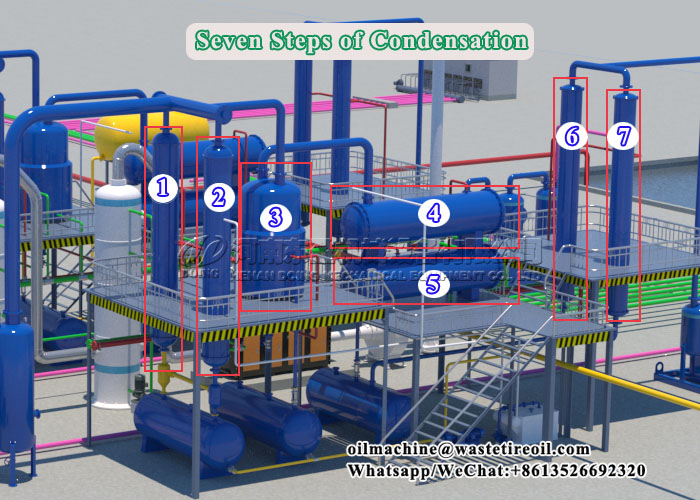

c) Cooling: The oil and gas are condensed into pyrolysis oil through the cooling system. To achieve optimal cooling and high oil output, our pyrolysis plant adopts a 3-step cooling system, including 2 vertical condensers, 2 horizontal condensers, and 2 cooling towers.

Mutiple stage cooling system of DOING pyrolysis plant

d) Exhaust Gas Recycling: During the pyrolysis process, in addition to oil and gas, there will be non-condensable exhaust gas, which can be directly recovered for heating the pyrolysis reactor, saving fuel.

e) Carbon Black and Steel Wire Slagging: After the oil and gas are discharged, the residual materials inside the reactor, mainly consisting of steel wire and carbon black from the tires, need to be discharged for further pyrolysis.

Customers visiting pyrolysis plant manufacturer in China HENAN DOING

Henan Doing Environmental Protection Technology Co., Ltd. is highly praised and trusted by domestic and international users for its commitment to safety, high efficiency, low consumption, excellent service, and technological expertise. We sincerely welcome customers from all over the world to visit us or send us your inquiry about our pyrolysis plant!