Waste oil to diesel distillation plant

Nowadays, everything is evaluated by quality in the competitive market, and no exception for fuel oil. While pyrolysis oil derived from waste tires, rubber, or plastics has proven useful in powering generators, ships, and trucks, many industries are now seeking higher-value end products such as diesel and gasoline. Besides that, some recycling companies want to re-refining used oil into diesel fuel.

This growing demand for premium fuels has led to the rise of waste oil distillation plants. These plants offer a cost-effective, eco-friendly solution with high profitability. They efficiently convert waste oils like pyrolysis oil, used motor oil, waste engine oil, other industrial waste oils and even heavy mazut fuel into high-quality non-standard diesel. And the final diesel has wider applications, such as diesel generators, tractors, heavy machines, even tractors, trucks, etc. The recovery rate of used oil in such used oil refining plants is approximately 75%~85%, making them a valuable investment for anyone looking to turn waste into a resource.

Convert waste used oil to diesel refining machine

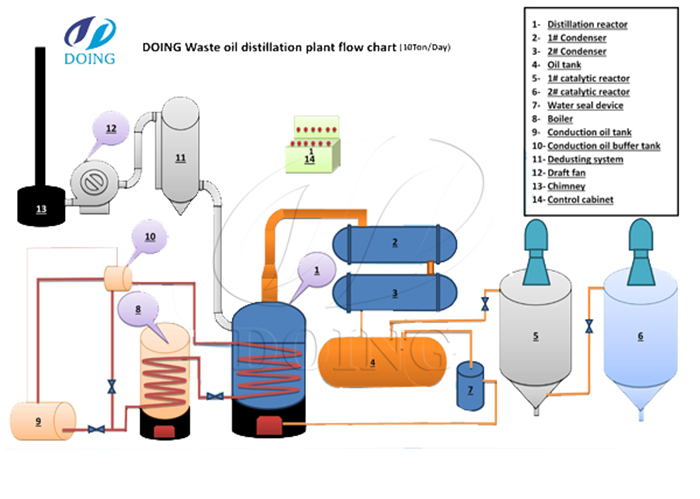

DOING advanced waste oil distillation plants employ a sophisticated yet straightforward process to maximize your return on investment and environmental impact. Here's how we transform used oil into diesel:

Waste oil to diesel conversation process flow

Feeding the Raw Material: The first step involves pumping the raw material into the distillation reactor using an oil pump. The feeding inlet is then sealed to ensure the reactor remains fully enclosed.

Heating the Reactor: The reactor is heated using fuel sources like coal, wood, natural gas, fuel oil, or electricity. As the temperature rises, the liquid oil gradually turns into oil gas. This gas is then cooled and condensed through a cooling pipe and condenser, resulting in the production of fuel oil, which is stored in the oil tank. To obtain high-quality diesel, the reactor temperature needs to be controlled to above 150°C. And used oil decolor and filter system is recommended to get bright color diesel.

Recycling Uncondensed Gases: Some gases, such as Methane, Ethane, Propane, and Butane, which cannot be liquefied, are recycled back into the furnace to continue heating the reactor. This ensures energy efficiency and reduces waste.

Smoke Treatment: Burning fuel materials can generate smoke. This is effectively processed by a dedusting system, ensuring that the smoke is fully treated and does not pollute the environment.

Emission Control: The exhaust gas generated is directed into the exhuast gas purification system and then the chimney, where it is drawn up by the draft fan. Before being emitted into the atmosphere, the exhaust is purified, ensuring no harmful emissions and no pollution.

When considering waste oil distillation plants, there are two main distillation technologies available for converting used oil to high-quality diesel:

1. Solid Catalyst Refining Technology (High Automation, High Efficiency)

This technology is highly automated, offering significant efficiency and large-scale processing capabilities. It is ideal for handling larger quantities of waste oil (typically 5 tons or more). Solid catalyst refining technology is a popular choice due to its ability to process a wide range of oils, including pyrolysis oil, used motor oil, waste engine oil, and more. It has a high conversion rate and produces high-quality diesel with minimal maintenance.

2. Liquid Catalyst Refining Technology (Lower Initial Investment, Lower Efficiency)

Liquid catalyst technology uses acid and alkaline solutions for the refining process. While this method typically handles smaller batches (starting from around 500 kg per batch), it requires a lower initial investment and is suitable for smaller operations. However, its processing efficiency is generally lower compared to solid catalyst technology, making it a more cost-effective option for businesses just starting out or those with lower processing demands.

Catalyst technologies of used oil to diesel distillation plant

Whether you prioritize automation, output volume, or startup cost, we can help you select the system that maximizes both performance and return on investment.

If you are interested in converting waste oil into high-quality diesel, we China Henan Doing Company invite you to contact us. DOING team of experts is ready to provide you with a detailed consultation on choosing the best solution for your needs. Let us help you start your eco-friendly and profitable waste oil distillation plant project today!