Plastic pyrolysis oil is a hydrocarbon product---fuel oil, produced waste plastics pyrolysis machine in an oxygen-free or oxygen-deficient environment through the process of thermal pyrolysis, condensation and recovery.

Hundreds of millions of tons of plastic waste are generated globally each year, known as "white pollution" and a heavy burden on the environment. But have you ever considered that this discarded waste is actually an untapped "oil field"? Plastic pyrolysis oil is the key to unlocking this treasure trove. It is essentially a "re-extraction" of petroleum resources, as plastic itself is a derivative of petroleum.

Waste plastic to fuel oil recycling pyrolysis plant

①What kind of pyrolysis oil is it? Plastic pyrolysis oil is a high-calorific value, widely used fuel oil that can be used as a heavy fuel oil substitute in industrial kilns, heating furnaces or boilers, power plants, and other heating applications.

②Color and Properties: It is typically brown or dark yellow in color, with a texture similar to ordinary diesel or heavy fuel oil. The specific color varies slightly depending on the type and purity of the raw plastic.

③What is its calorific value? Plastic pyrolysis oil generally has a high calorific value, typically between 10,000 and 10,500 kcal/kg, close to that of standard diesel and significantly higher than coal, resulting in excellent combustion efficiency.

④Main Applications:

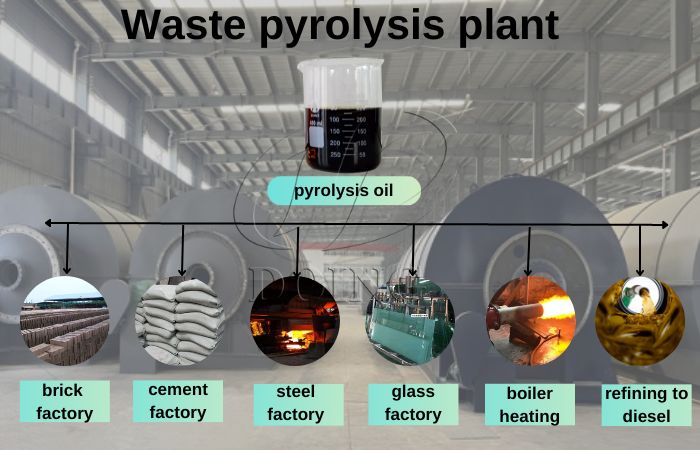

Waste plastic pyrolysis oil usages

Industrial Fuel: Used in industrial kilns requiring high temperatures, such as those in steel mills, cement plants, glass processing factories, and brick making factories, etc.

Boiler Fuel: Powering heating or steam boilers in factories.

Power Generation Fuel: Can be used in heavy oil generator sets for power generation.

Further Refining: After deep refining by pyrolysis oil refinery plant, it can be produced into non-standard diesel for use in heavy machinery, trucks, ships, tractors, etc.

Choosing plastic pyrolysis oil is not only an alternative energy source, but also a sustainable path to transforming pollution into profit.

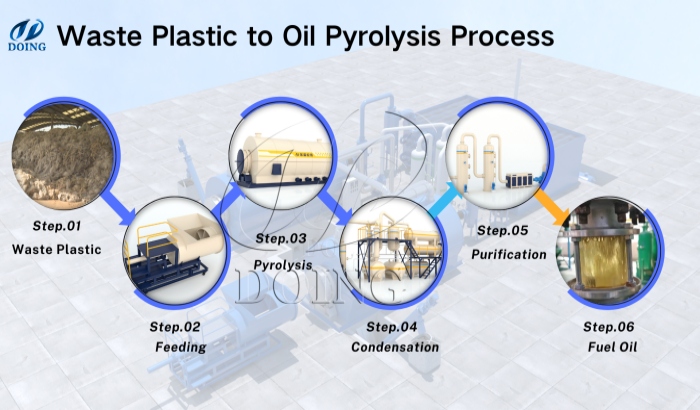

The process of transforming solid waste plastic into liquid fuel oil may seem magical, but it actually relies on a mature and stable pyrolysis process. The core plastic to fuel oil pyrlysis process is as follows:

Pyrolysis waste plastic to oil machine process flow

Loading and Feeding: Sorted waste plastics are fed into the feeding system via an automatic conveyor or manually, ensuring a continuous and efficient production process.

Pyrolysis: After loading, the plastic pyrolysis machine reactor is sealed and heating begins. In an oxygen-free environment, the temperature inside the pyrolysis reactor is gradually heated to approximately 350°C-450°C. At this temperature, the macromolecular chains of the plastic break, converting them into a mixture of oil gas.

Oil Gas Condensation: The generated high-temperature oil and gas enter the condensation system through a pipeline. After multiple cooling stages, most of the condensable oil and gas are liquefied into liquid plastic pyrolysis oil and flow into a storage tank.

Exhaust Gas and Residue Treatment:

Non-condensable Combustible Gas: The non-liquefiable combustible gases (primarily alkanes) generated during the pyrolysis process are recovered and returned to the bottom of the reactor to be used as heating fuel, significantly reducing the energy consumption of the entire plastic pyrolysis oil production process.

Solid Residue: After the reaction is complete, a small amount of solid residue—carbon black—remains. Carbon black is also a valuable industrial raw material that can be processed into briquettes or used as a filler in plastic masterbatch.

The entire plastic pyrolysis oil production process forms an energy-saving, environmentally friendly, closed-loop production model, truly achieving "full utilization."

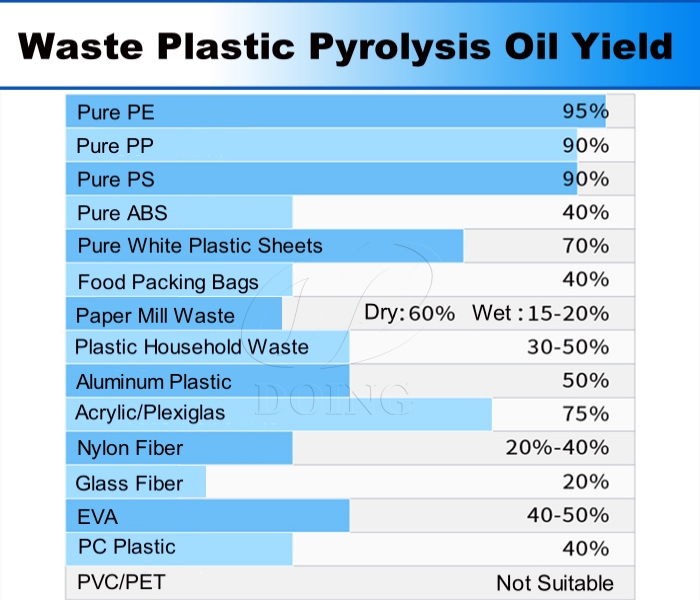

Not all plastics produce the same amount of pyrolysis oil. Understanding the relationship between raw materials and output is key to ensuring your return on investment. Below are typical oil yields for several common scrap plastics:

Waste plastic pyrolysis oil output

Plastic Type &Common Items&Average Oil Yield Characteristics

PE (Polyethylene): Plastic bags, plastic wrap, milk bottles. Approximately 95% Highest oil yield, high-quality oil, ideal for thermal cracking.

PP (Polypropylene): Microwaveable lunch boxes, buckets, and basins. Approximately 90% Extremely high oil yield, high calorific value oil, and a wide range of applications.

PS (Polystyrene): Foam lunch boxes, appliance packaging. Approximately 90% or more High oil yield, but produces a high level of oil and gas, requiring a more efficient condensation system.

Mixed plastics: household plastic waste, agricultural plastic film waste, and aluminum-plastic composite waste, can all be used as pyrolysis feedstock, with an oil yield of approximately 25-50%.

PET (polyester): beverage bottles, which have an extremely low oil yield and are not suitable for direct pyrolysis. PET pyrolysis primarily produces monomers of terephthalic acid and ethylene glycol, not fuel oil.

PVC (polyvinyl chloride): water pipes, doors, and windows are prohibited from use in the pyrolysis process. PVC pyrolysis produces highly corrosive and toxic gases such as hydrogen chloride, which can seriously damage equipment and pollute the environment.

Key Recommendation: To achieve the highest oil yield and maximize equipment life, we strongly recommend that customers primarily use polyolefin plastics such as PE, PP, PS or mixed plastic as waste plastic pyrolysis machine feedstock for pyrolysis oil extraction, and strictly separate PET and PVC.

A. Environmental Value

Converting waste plastics that are difficult to recycle or destined for landfill into useful energy and chemical feedstocks reduces waste disposal pressure and greenhouse gas emissions.

B. Economic Potential

As a localized fuel and chemical intermediate, pyrolysis oil can reduce transportation costs, mitigate the impact of crude oil price fluctuations on businesses. And plastic pyrolysis process create high-value-added waste plastic recycling business.

C. Technical Maturity and Scalability

Modern pyrolysis processes are feasible for scale-up and scalability, which has been in operation for about 20 years. Equipment manufacturers can provide complete plastic waste treatment and recycling solutions, from single-line pilots to industrial scale-up, including intelligent control, energy efficiency optimization, and environmental management systems.

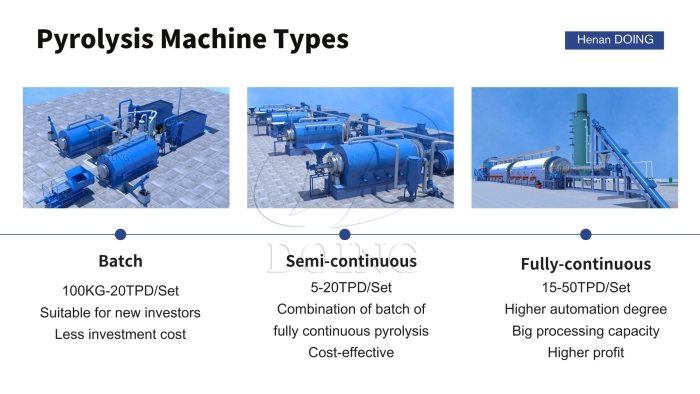

Batch continuous types of waste plastic pyrolysis oil machines for sale

D. Market Opportunities

As more and more oil-consuming heavy industries, refining, energy, and renewable resource companies seek to diversify their feedstocks and optimize their carbon footprint, plastic pyrolysis oil is becoming a new engine connecting waste plastics recycling with core business growth.

Faced with enormous market opportunities and complex technical details, choosing a reliable plastic pyrolysis machine manufacturer is crucial. Here are some reasons why Henan Doing Company becomes the preferential choices for plastic pyrolysis solution:

Efficient and Energy-Saving Plastic Oil Pyrolysis Process: DOING waste plastic pyrolysis machine features a unique furnace design and condensing system, ensuring high pyrolysis oil yields and low energy consumption.

Safety and Environmentally Friendly Features: Multi-level safety devices and an exhaust gas treatment system throughout the system ensure safe and environmentally friendly production that complies with environmental requirements.

Durable Quality: Core components are manufactured from special steel, which is heat-resistant and corrosion-resistant, ensuring a long service life.

Comprehensive Support: From site planning and equipment installation to personnel training and after-sales maintenance, we offer one-stop services to help your project go smoothly.

Rich Experience: More than 14+ years plastic pyrolysis oil machine R&D, manufacturing, export experience. We have successful pyrolysis machine installation project cases all over the world, such as India, Indonesia, South Africa, Fiji, America, Russia, Thailand, Vietnam, Mexico, Brazil, Poland, Italy, etc. And Henan Doing Company won many certifications, such as “High-tech Enterprise”, over 20+ patent certificates, etc.

Waste plastic is a misplaced resource. When you invest in a plastic pyrolysis oil production project, you're not only building a business, but also contributing to the sustainable development of plastic recycling. Contact us today for a personalized project proposal and quote of waste plastic pyrolysis machine!