How to start waste tire pyrolysis plant project? product introduction

For customers who want to purchase waste tire pyrolysis plant, they will be more concerned about how to start waste tire pyrolysis plant project. Here, Doing Group will tell customers the preparations before starting the waste tire pyrolysis plant project.

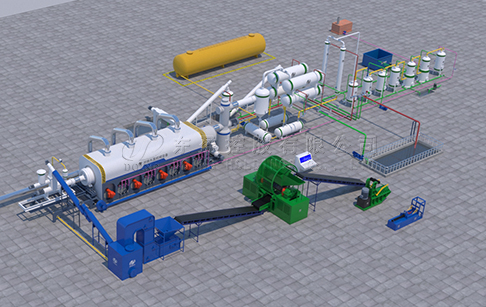

Waste tire pyrolysis plant project

Waste tire pyrolysis plant project

First of all, when customers has studied the waste tire pyrolysis plant project and decided to start this project, customers need to prepare a piece of land for the construction of waste tire pyrolysis plant workshop. Usually a waste tire pyrolysis plant requires about 600 square meters of land. Henan Doing provides two types of waste tire pyrolysis plant: batch waste tire pyrolysis plant and continuous waste tire pyrolysis plant. The two types of waste tire pyrolysis plant have different daily capacity, and occupy different land area. If customers want to know more information about how to choose the area of land, please consult us, our engineers will provide suitable solutions for customers.

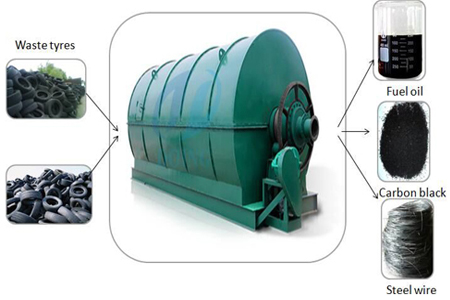

Waste tire pyrolysis plant

Waste tire pyrolysis plant

Secondly, to carry out the waste tire pyrolysis plant project, in addition to the land, customers need to have sufficient raw materials-waste tires. Our common waste tires mainly include: automobile tires, truck tires, engineering tires, automobile tires, motorcycle tires, bicycle tires, etc. After you have the raw materials, you can make a preliminary plan for the project, such as how many raw materials to collect in a day and how many raw materials to process each day. You can choose the appropriate waste tire pyrolysis plant according to the daily capacity. The daily capacity of Doing Group waste tire pyrolysis plant is between 100Kg and 50 tons. We can also provide customers with personalized solutions to meet the needs of different customers.

Oi yield of different waste tire

Oi yield of different waste tire

Thirdly, after determining the land and raw materials, customers need to calculate the amount of investment in the waste tire pyrolysis plant project. These investment amounts roughly include: waste tire pyrolysis plant cost, land cost, raw material cost, labor cost and daily electricity cost for waste tire pyrolysis plant operation. Doing Group continuous waste tire pyrolysis plant adopts PLC control system, which has a high degree of automation and is convenient for workers to operate. The main advantage is that continuous waste tire pyrolysis plant has a continuous feeding and slagging discharge system, which greatly improves production efficiency. One production line requires 1-2 people, which saves manpower, has low investment and high profits.

Waste tire pyrolysis plant project investment

Waste tire pyrolysis plant project investment

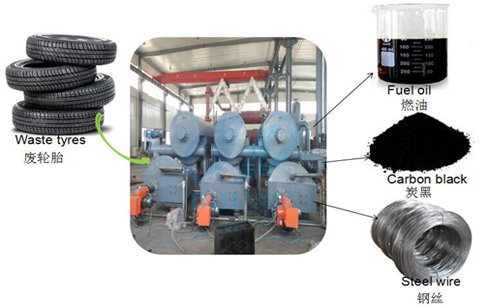

Fourthly, after calculating the investment amount , customers should investigate the waste tire pyrolysis plant project market, calculate the cost of obtaining raw materials and how to sell the end products - fuel oil and carbon black. Calculate how much money can be obtained from the waste tire pyrolysis plant project based on market prices.

Finally, after preparing for the above four aspects, you can prepare for the final step of the project, which is to inspect the manufacturer of waste tire pyrolysis plant and choose a machine manufacturer that can provide you with reliable, effective and high-quality equipment. Doing Group has been dedicated to waste tire pyrolysis plant for more than 10 years, is a comprehensive environmental protection equipment manufacturing enterprise integrating design,research and development,manufacturing,sales and after-sales service. Our equipment are sold well in more than 90 countries and regions, and have won praise an trust from customers all over the world.

Waste tire pyrolysis plant installation

Waste tire pyrolysis plant installation

The above is the preparation required to start the waste tire pyrolysis plant project. If customers want to know more information about starting the project of waste tire pyrolysis plant or waste tire pyrolysis plant, welcome consult us feel free, we will provide customers with the most reasonable and reliable services and equipment.

| Technical parameter of how to start waste tire pyrolysis plant project? | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd