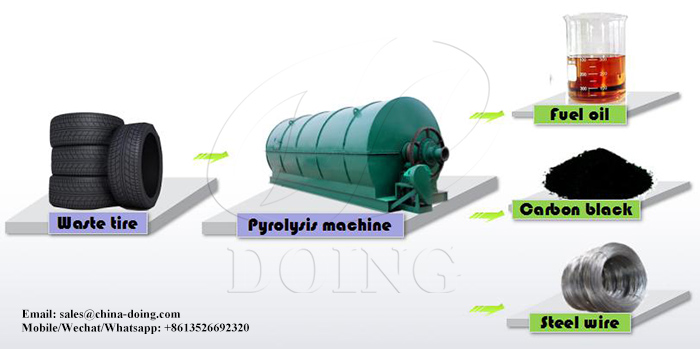

DOING fully automatic waste tyre pyrolysis plant product introduction

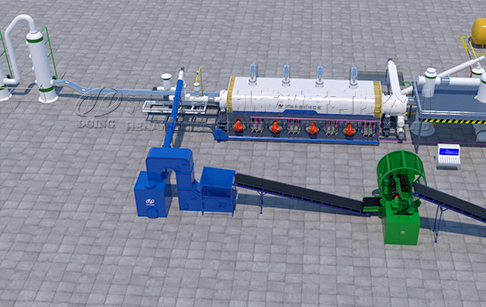

DOING fully automatic waste tyre pyrolysis plant

DOING fully automatic waste tyre pyrolysis plant

Process Description:

a.Heating in advance to make the temperature of the reactor rises up to about 300℃, fuel choose can be gas or oil.

b.Turn on the auto-feeder, small pieces of tyres loaded into reactor and pyrolysis begins; reaches certain temperature and the gas oil is generated from the waste.

c.oil gas generated and condensed into fuel oil stored, sync gas recycled and used as fuel during operation; at the same time, carbon black and steel wires in short also discharged from the auto-discharging system. The Steel metal and carbon black separated automatically and stored.

d.Since one batch begins, it lasts for about 20days continuously, without any stop.

e.Then stop the motor, and do the maintenance.

The next batch of process begins again.Doing fully automatic waste tire pyrolysis plant final product and usage

| NO | Name | Percentage | Usage |

| 1 | Tyre fuel oil | 45% | 1.Can be sold directly 2.Can be as fuel 3.Can be used industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic factory. |

| 2 | Carbon black | 30% | 1.Can be sold directly 2.Can be used electric cable jacketing,black nylon bag,rubber additive |

| 3 | Steel wire | 15% | 1.Can be sold directly 2.Make steel bloom by use hydraulic press-packing |

| 4 | Oil gas | 10% | 1.Can be as fuel burn by use gas burning system 2.Extra gas also be storage as fuel for other heating |

| Technical parameter of doing fully automatic waste tyre pyrolysis plant | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, waste plastic, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd