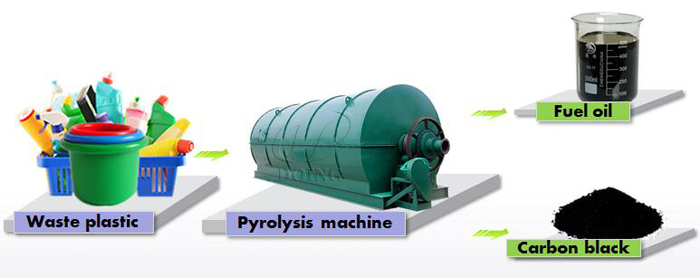

Convert plastic to fuel oil line product introduction

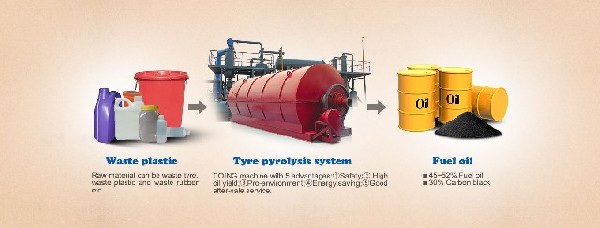

Convert plastic to oil is a new technology. By the technology, we can convert the plastic, which is seen as waste to oil. With years researching and developing,we have manufactured the latest generation convert plastic to fuel oil line.According to the feedback of customers, we consistently improve the quality of this machine. Finally, we manufactured the latest generation machine. Compared with the old machine, many advantages with the latest generation machine:

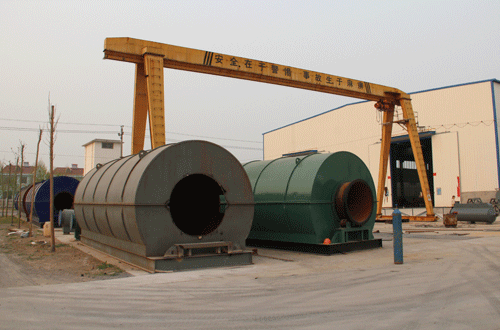

convert plastic to fuel oil line

1. The latest generation convert plastic to fuel oil line adopt the newest technology toreduce the pollution to the environment, it produce nearly no pollution to theenvironment. It absolutely meets the stand of the environmental protection. And meet the command of the notion of sustainable development.

2. The latest generation convert plastic to oil line is more effective. With fewer raw materials it can produce crude oil as many as it can. And the time is shorter compared with old machine. What is worse, 2 workers are enough tooperation the machine.

3. The traditional way to convert plastic to fuel oil is to heat the plastic when the temperature reached its boiling point,let it vaporize and then condense the vapor. Finallywe will get liquid oil. The latest generation convert plastic to fuel oil line adopts chemical process which breaks long chains into shorter ones.This allows a refinery to turn diesel fuel into gasoline depending on the demand for gasoline. So we can get higher quality oil.

4. The latest generation convert plastic to oil machine is the cheapest during the history of my company. And it is cost-effective.it can maximize save the prime cost, and create more economics profits.

We put out heart and soul into serving our customers. It is a wisdom choice to have a corporation with us. We are Henan DOING Mechanical Equipment Co,Ltd. Welcome your visit!

| Technical parameter of convert plastic to fuel oil line | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste plastic, waste tyre, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd