Tire to fuel oil recycling machine product introduction

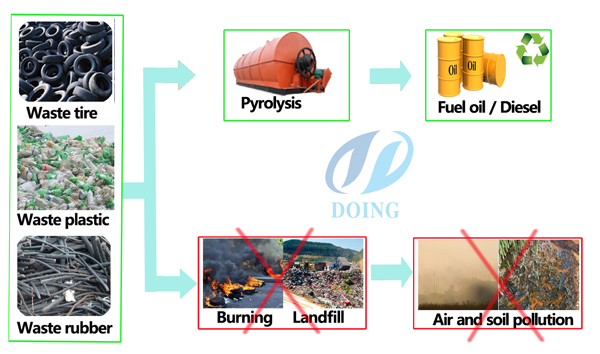

Waste tire is seen as hazard waste in society. They are consistently occupying the land we live, polluting our environment and so on. We have tire to fuel recycling plant to recycle the waste tire to fuel. The tire to fuel oil recycling plant can deal with the waste tire or other waste perfectly.A machine which can convert waste to energy. Tire to fuel is a good method to recycle the waste tire. Thus waste tire will not be serious problem for us.

Tire to fuel oil recycling plant is mainly from the process named pyrolysis. We put the collected Waste tire into sealing reactor. The environment of the reactor is in absence of oxygen. When the temperature in reactor reached about 180 Celsius degrees, the waste tire will vaporize. Then the oil gas will go into the condenser. In the condenser, the waste oil will be cooled into liquid; the liquid is called liquid oil. During the process, some oil gas which cannot be condensed will be recycled to heat the reactor instead of the fuel such as coal, natural gas and so on.

The fuel oil extracted from the waste tire can be used for heating fuel, glass factory, cement factory, and so on. The fuel oil is a good alternative to the traditional energy such as petroleum based crude oil, natural gas and so on.

During the process it will also generate some carbon black, When one batch is finished we will discharge the carbon black which precipitates in the foot of the reactor. The carbon black is no pollution to the environment.

If the process performed well, the process will be very clean and green. The fuel used to heat the reactor is from the plant itself. The only solid is the carbon black which is not pollution to the environment at all. During the process, the water is only used to cool the oil gas. The water is not in –contact with the process itself. So the water is clean and uncontaminated.

Converting tire to fuel is an advancing in the technology of recycling waste tire.

| Technical parameter of tire to fuel oil recycling machine | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tire, waste plastic, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd