The 5th generation improved pyrolysis plant product introduction

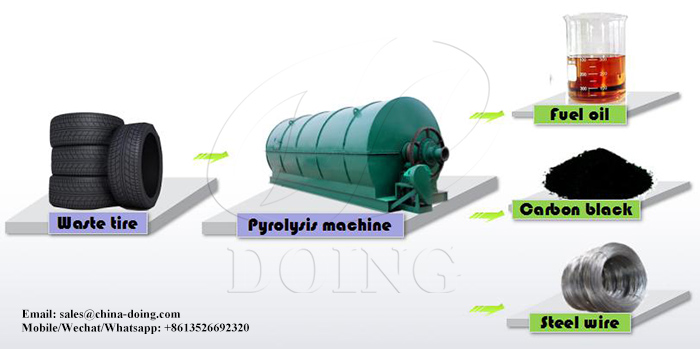

Technology is advancing with the development the environment. pyrolysis plnat is a machine converts wasteplastic to oil. It is a in the absence of hydrocarbon. So we will introduce the difference from the 1th generation pyrolysis plant to 5th generation pyprolysis plant.

With the development of the environment and economics. There is a higher stand about environment protection. And we are in eager demand of energy. We improved the technology of our pyrolysaaaaaaaaaaa plant to meet the demand of the environment, relieve the lack of the energy in the world. Higher yield of oil output and more serious environmental pollution is the two main key of the improved 5th generation pyrolysis plant.

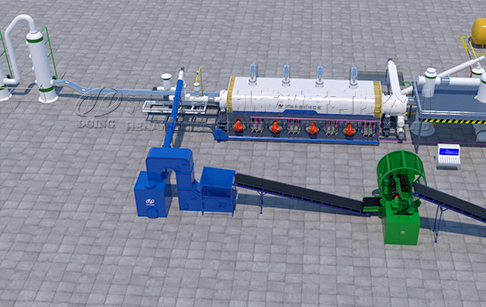

Higher output of oil: the 4th generation pyrolysis plant has about a 45 squares area of condensing. The condense of the area are limited. While improved, we enlarge the area of condensing. The oil yield output is higher and more quality. The oil is more purifier.There are total 57 condensers pipes in the condenser with an diameter 14mm.The condense pipe will enlarge the condensing area and the contact area between the oil gas and cooling water.

More environmental friendly:the waste oil gas which can not be condensed will be collected and recycled back to heat the reactor.Take the 10T plastic pyrolysis plant for example,we can save 45% energy available.And the dedusting system will remove the waste gas,waste solid.And specilized design for carbon black collecting system will deal with the carbon black well without any solid pollution to the environment.what is more the discard is collected well which the waste plastic or waste Tyre generated.Sealing all the details well thus avoid gas leak and smelly.

Then the safety of the pyrolysis plant is very important.The 5th generation plastic to oil pyrolysis plant is safer compared with before.Reactor with auto welding avoid direct heat.Indirect heat will be sager and decrease the rate to happen accident. The new designed vacuum system will prevent the oil gas being back to cause accident.

Generally speaking,compared with the pyrolysis plant befor The 5th generation pyrolysis plant is more environmental friendly,safer,and energy saving.

| Technical parameter of the 5th generation improved pyrolysis plant | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, waste plastic, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd