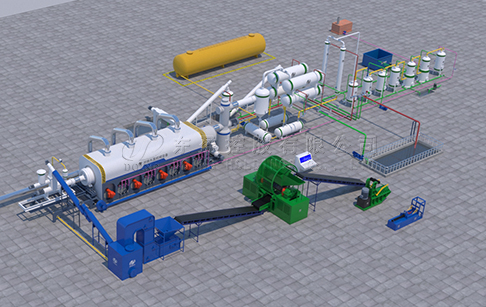

Operational process of tyre pyrolysis plant product introduction

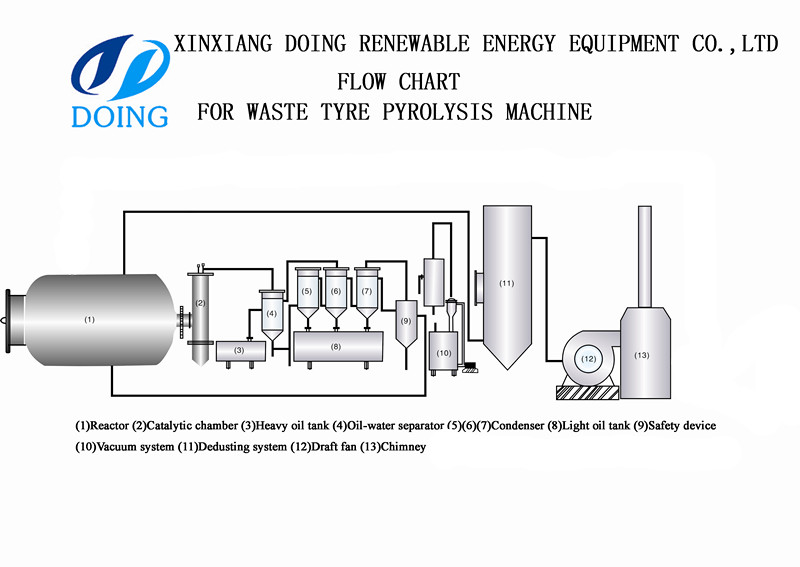

The flow chart of tyre pyrolysis plant for 6T capacity

Xinxiang doing mechanical equipment co.ltd are supplier and manufacturer of the waste tyre pyrolysis plant; we specialized in manufacturing tyre pyrolysis plant for many years. We exported our pyrolysis plant to many countries in the world. The tyre pyrolysis plant is a green technology to convert the waste tire to oil for fuel.

The flow chart of our tyre pyrolysis plant is as below:

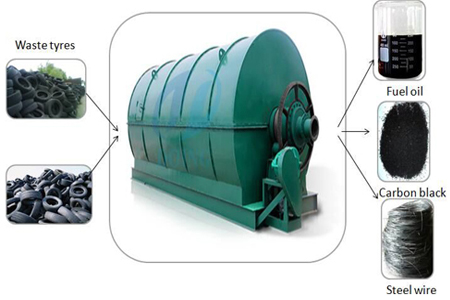

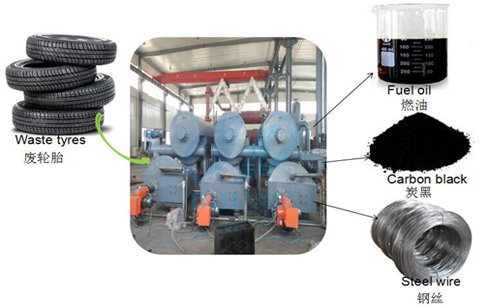

First we add the raw material waste tyre into the reactor. And we heat the reactor under to a high temperature, and then the raw material will generate oil gas. Then the oil gas will go into the condenser. During the transfer of the oil gas, the oil gas will go cross a chamber when the temperature of the oil gas cooled down they will become liquid. Most oil gas will become light oil, and some oil will become heavy. The heavy oil will go into the heavy oil tank. Then preliminary condensed oil will go into the filtering machine. Then now the oil is clean. The oil will finally go into the oil tank. When on batch is finished we can open the oil tank and take out the oil.The oil gas which cannot be recycled to heat the reactor.

We have specially designed condenser to enlarge the area of cooling as a result of getting a high oil yield rate. And the well sealing system will make the waste tyre burned fully. During the process the react is safe. For we have the vacuum system to avoid the oil gas leak and explosion.

The process of the tyre pyrolusis plant is clean. There will be no pollution to the environment, we have dedusting system to remove the dust.

| Technical parameter of operational process of tyre pyrolysis plant | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, waste plastic, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd