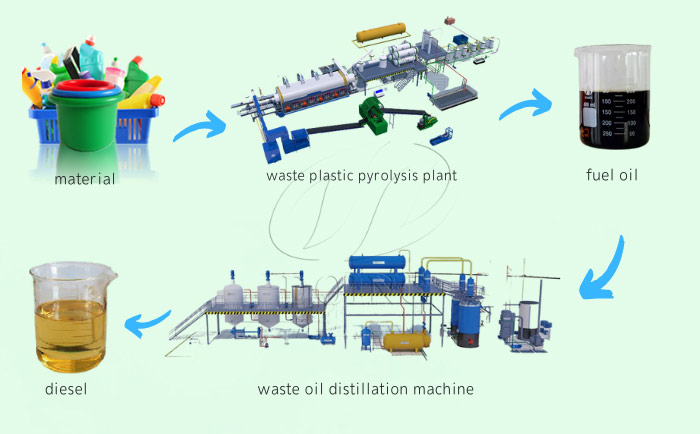

Converting plastic to diesel needs two machines: waste plastic pyrolysis plant and waste oil distillation machine. With the waste plastic pyrolysis plant, we can convert plastic to pyrolysis oil, which is the first step to convert plastic to diesel; then we need to use the waste oil distillation machine to refine pyrolysis oil to diesel.

The detailed recycling process of converting plastic to diesel is as follows:

1. Pyrolyzing waste plastic

Put waste plastic to the reactor of the waste plastic pyrolysis plant and heat the pyrolysis plant. When heat the temperature to 200~380℃, the plastic will be pyrolyzed to oil gas.

2. Cooling oil gas

The evaporated oil gas passes through the multi-stage cooling system and cools into plastic pyrolysis oil.

3. Distilling pyrolysis oil and catalysis

Put the pyrolysis oil into the distillation reactor of the waste oil distillation machine with oil pump and fill the heat conduction oil with the whole heating system. Heat the reactor and the pyrolysis oil will be evaporated and catalyzed. Then the vapor goes through the cooling system, and we can get the liquid oil.

4. Cooled liquid oil purification

We can adopt the purification system to remove the color and improve the odor of the cooled oil, then we can get good quality diesel.

DOING plastic to diesel recycling machine

DOING plastic to diesel recycling machine

Obviously, with these two machines, we can convert waste plastics to diesel easily. Here DOING Company can provide two schemes for you about the matched machines purchasing.

(1) Small scale waste plastic to diesel plant

For this type, we have the capacity of 100KG and 500KG, which is free installation and easy to operate. If you want to carry out trial running or you are a new investor, this one will be a better choice.

(2) Middle/Big scale waste plastic to diesel plant

For this type, we have the pyrolysis plant of 1TPD to 20+TPD and the refinery plant of 1TPD to 14+TPD, which has big processing capacity, high efficiency and saves labor and time. If you have abundant plastics to recycle and have enough budget, you can choose this scheme.

Project cases of DOING pyrolysis plant

These two different recycling schemes both can get 85% high quality diesel, which can be used in boilers, generators, burners, agricultural machinery, construction machinery, ship engines, etc.

DOING has more than 13 years experience in manufacturing waste plastic pyrolysis plants and refinery plants and helped lots of customers carry out similar projects in Pakistan, Thailand, Malaysia, Ecuador, Nigeria, Kenya, etc. If you are interested in converting plastic to diesel, please feel free to contact us for more details.