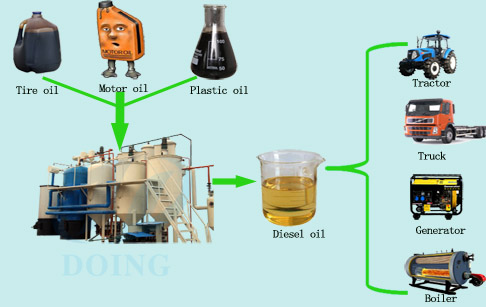

Used motor oil to diesel fuel machine

Recycling your used motor oil into diesel is efficient way to save both money and the environment. Used motor oil can generate quality energy, if processed, stored and handled with care.

Doinggroup develop innovative used motor oil to diesel fuel technologies that recycle for the environmental benefits, and turn all kinds of waste oil into highly profitable diesel.

How to make diesel from used motor oil?

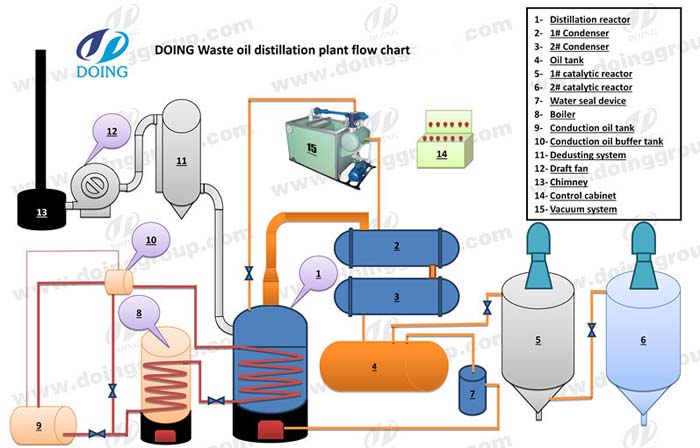

Used motor oil to diesel fuel working process

1. Pre-treatment device for raw material: waste oil is fed into refinery boiler after pre-treatment.

2. Refinery system: heat the waste oil to working temperature by using fuel oil, gas, coal etc. as heating materials. In the meanwhile, there are stir system and heat preservation system.

3. Cooling system: cool the gaseous hydrocarbon into diesel.

4. Interim storage system: base oil and diesel after cooling are stored here, and then put into oil tank.

5. Vacuum system: to meet the process required.

6. Filter system: rapidly filter mechanical impurities in the diesel produced, and got qualified diesel.

7.Finally, you can get 85% diesel from our used motor oil to diesel machine